Preparation method of nickel-coated copper powder for conductive rubber

A technology of conductive rubber and nickel-clad copper, which is applied in the direction of liquid chemical plating, coating, metal material coating process, etc., can solve the problems of high cost, increased energy consumption, environmental pollution, etc., and achieve the reduction of plating cost and saving Effects of energy consumption and water conservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

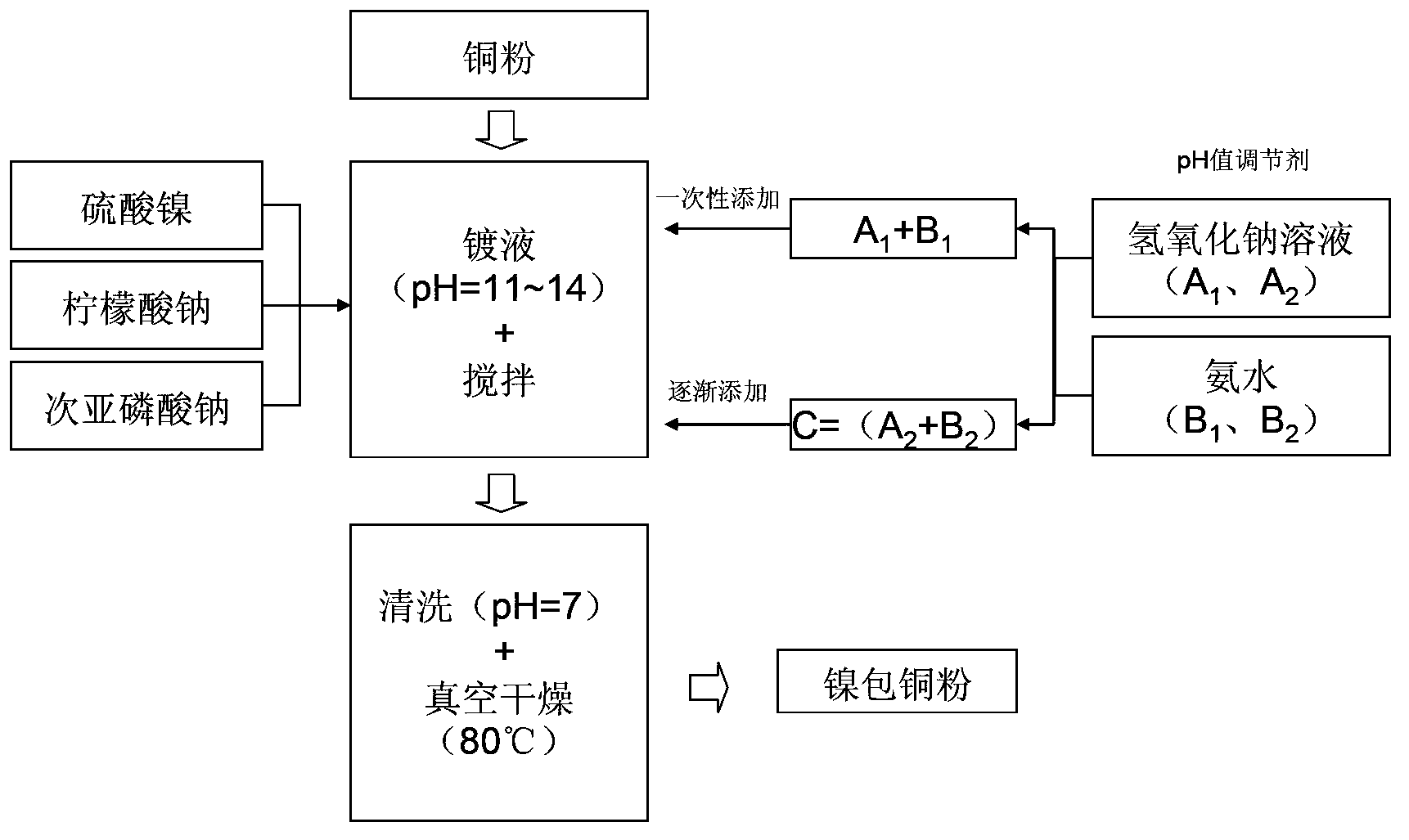

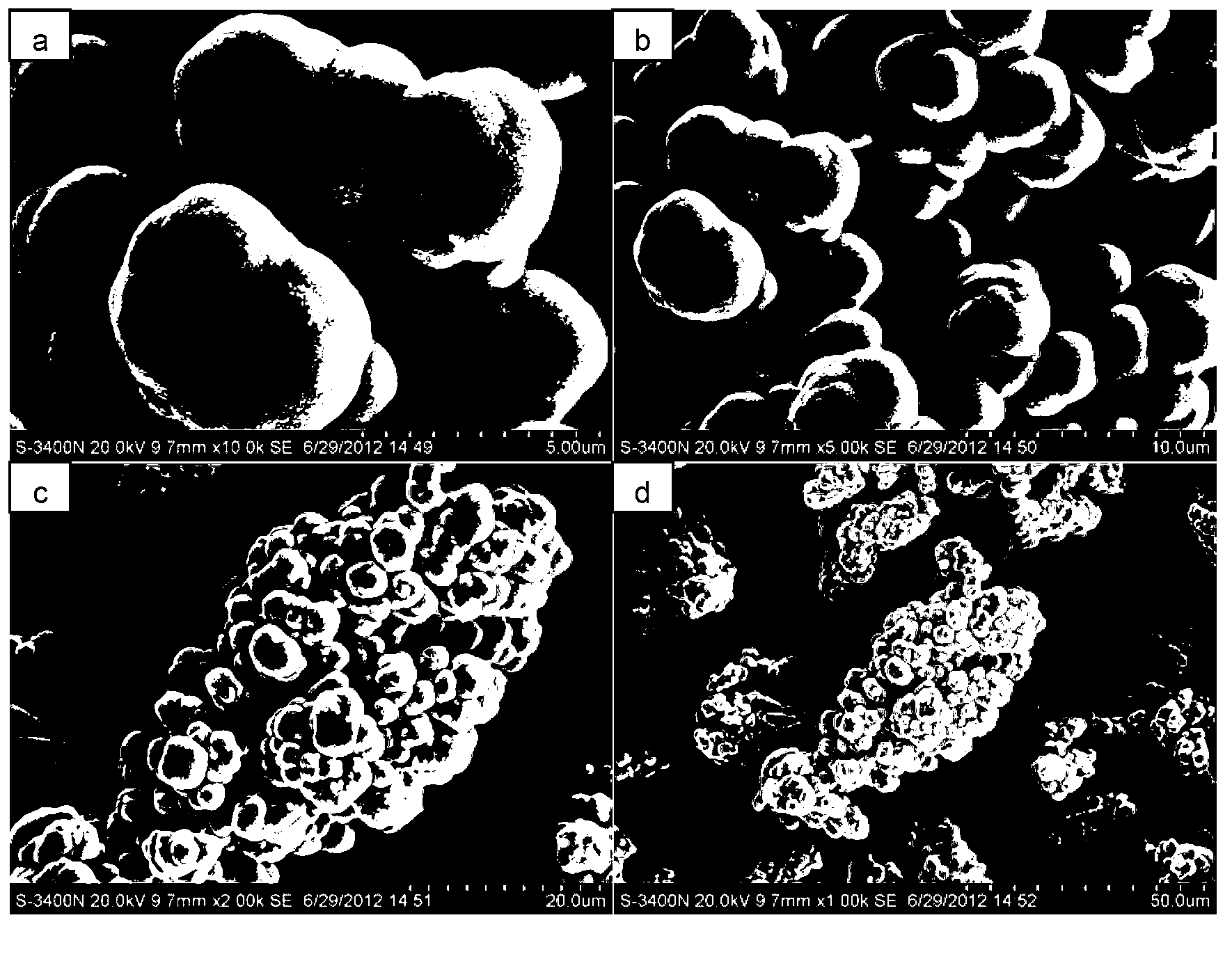

[0061] The nickel content of the design formula is 30%, the mass of copper powder is 2g, and the particle size of the powder is 75μm. Plating solution formula: nickel sulfate 39g / L, sodium hypophosphite 40g / L, sodium citrate 44g / L, copper powder loading 20g / L. The final plating solution volume is about 100ml, the plating pH=12~13, the preparation process is as follows figure 1 shown.

[0062] Weigh a 1 =a 2 =2.0g sodium hydroxide, dissolved to get A 1 、A 2 ; Measure B 1 = 10ml, B 2 =2ml; mixed solution A 2 with B 2 , to obtain a solution C ≈ 20ml, where a 2 The concentration in C is 100g / L, B 2 The concentration in C is 100ml / L; 1 , copper powder, B 1 Slowly add to the plating solution beaker in turn, stirring the plating solution continuously; the plating reaction time is 10-20 minutes, during the plating process, slowly add C solution dropwise for 20-30 minutes, the average rate is 1-2ml / min, to make the pH of the plating solution The value is maintained at (12-...

example 2

[0068] Design Example 1 comparative test, plating pH=11~12, other operations are the same as Example 1, EDS coating composition analysis is shown in Table 1.

example 3

[0070] Design Example 1 comparative test, plating pH = 13 ~ 14, other operations are the same as Example 1, the composition analysis of EDS coating is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Magnetization | aaaaa | aaaaa |

| Shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com