Method for preparing high purity level lithium hydroxide monohydrate

A pure grade technology of lithium hydroxide monohydrate, which is applied in the direction of lithium oxide;

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

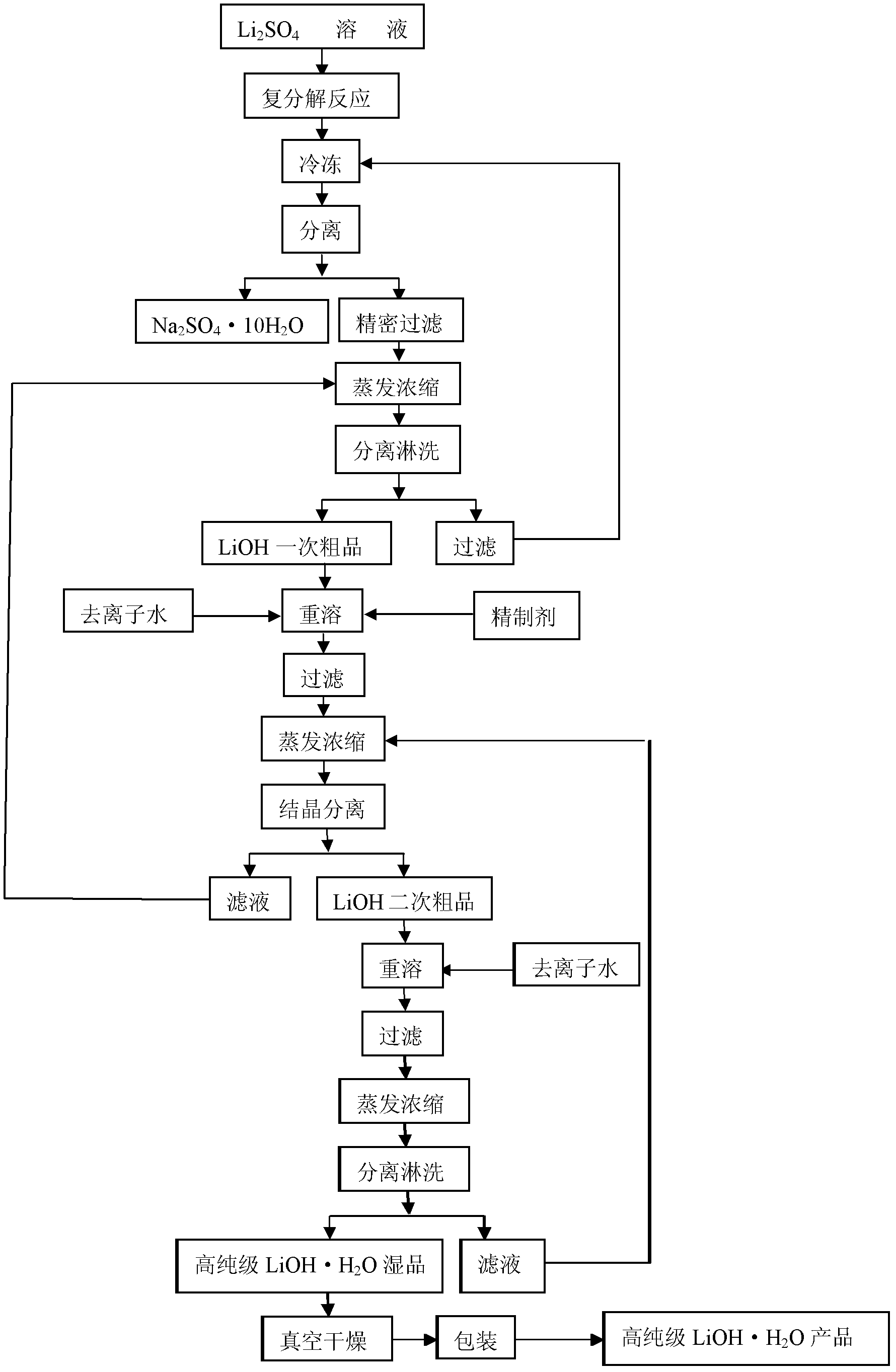

Image

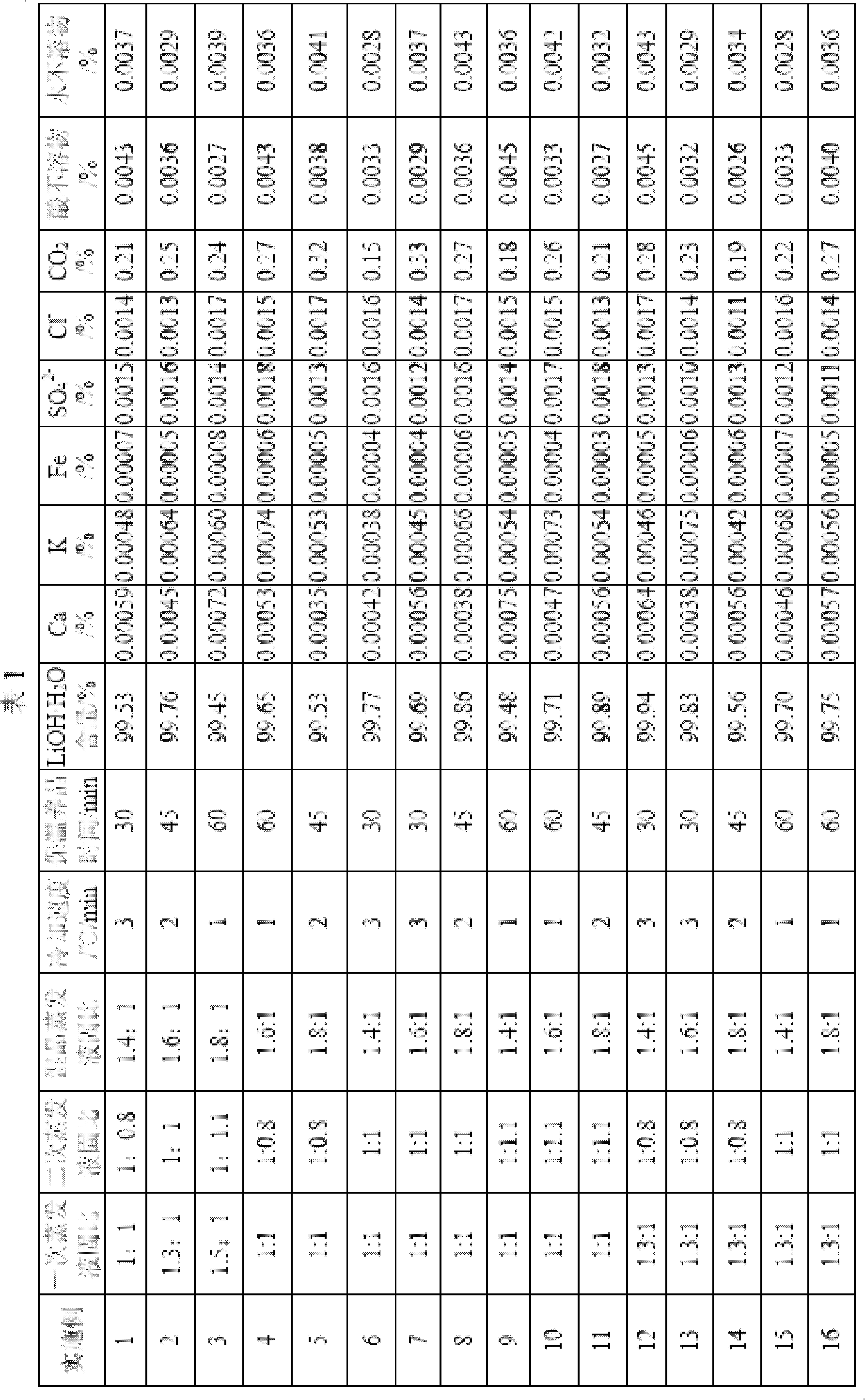

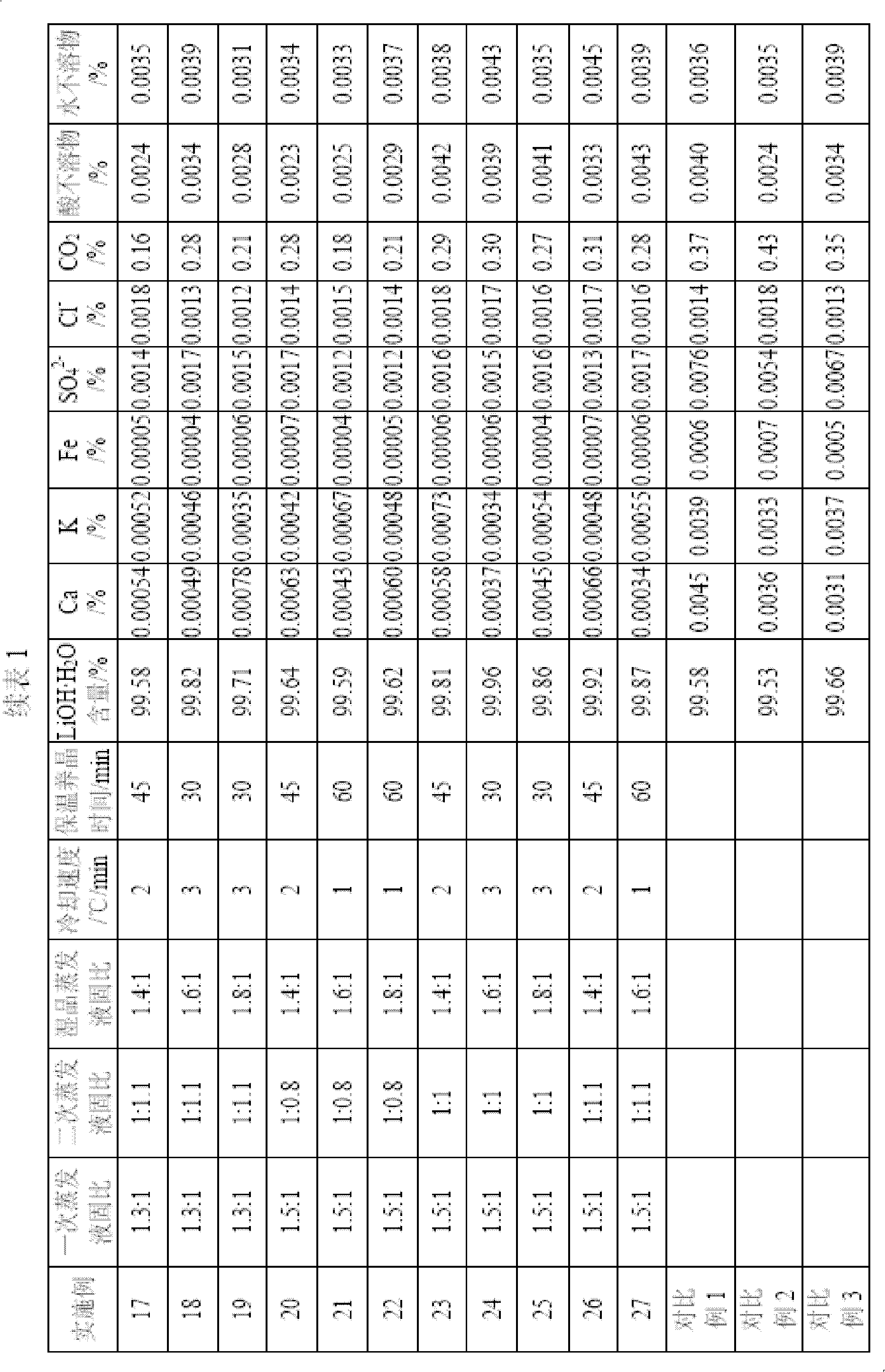

Examples

Embodiment 1

[0043] Example 1 High-purity grade LiOH·H 2 Preparation of O

[0044] (1), take Li 2 Li with an O concentration of 38 g / L 2 SO 4 Leach solution 10000ml, add Ca(OH) to it 2 Regulate pH=9, filter to obtain lithium sulfate primary purification solution, the concentration of impurity in the purification solution is reduced to Fe 3+ 0.38g / l, silicon 9.40g / l, aluminum 0.0032g / l, manganese 0.0027g / l. Add 1100g of sodium hydroxide to the primary purification solution of lithium sulfate, stir well to dissolve it completely, then cool it to -3°C while stirring, when the SO in the solution 4 2- When the concentration is 35g / l, it is separated by filtration to obtain Na 2 SO 4 10H 2 O solid and LiOH solution;

[0045] (2), the LiOH solution obtained in step (1) is filtered through a precision microporous filter tube to obtain the LiOH solution pure liquid; the concentration of impurity calcium in the LiOH pure liquid is 0.5g / l, and the concentration of impurity magnesium is 0.00...

Embodiment 2

[0054] Example 2 High-purity grade LiOH·H 2 Preparation of O

[0055] (1), take Li 2 Li with an O concentration of 38 g / L 2 SO 4 Leach solution 10000ml, add Ca(OH) to it 2 Regulate pH=10, filter to obtain lithium sulfate primary purification solution, the concentration of impurity in the purification solution is reduced to Fe 3+ 0.45g / l, silicon 8.3g / l, aluminum 0.0040g / l, manganese 0.0034g / l, then add 980g sodium hydroxide to the primary purification solution of lithium sulfate, fully stir to make it completely dissolve, and then put the It is cooled to -2°C, when SO in solution 4 2- When the concentration is 32g / L, it is separated by filtration to obtain Na 2 SO 4 10H 2 O solid and LiOH solution;

[0056] (2), the LiOH solution obtained in step (1) is filtered through a precision microporous filter tube to obtain the LiOH solution pure liquid; the concentration of impurity calcium in the LiOH pure liquid is 0.45g / l, and the concentration of impurity magnesium is 0....

Embodiment 3

[0065] Example 3 High-purity grade LiOH·H 2 Preparation of O

[0066] (1), take Li 2 Li with an O concentration of 38 g / L 2 SO 4 Leach solution 10000ml, add Ca(OH) to it 2 Adjust pH=10 to filter to obtain lithium sulfate primary purification solution, and the concentration of impurities in the purification solution is reduced to Fe 3+0.28g / l, silicon 8.5g / l, aluminum 0.0034g / l, manganese 0.0031g / l, then add 980g sodium hydroxide to the primary purification solution of lithium sulfate, fully stir to dissolve it completely, and then put the It is cooled to -6°C, when SO in solution 4 2- When the concentration is 28g / L, it is separated by filtration to obtain Na 2 SO 4 10H 2 O solid and LiOH solution;

[0067] (2), the LiOH solution of step (1) gained is filtered through precise microporous filter tube to obtain LiOH solution pure liquid; The concentration of impurity calcium in described LiOH pure liquid is 0.37g / l, the concentration of impurity magnesium is 0.0065g / l ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com