Gradient-doped high-nickel ternary positive electrode material and preparation method thereof

A positive electrode material, gradient doping technology, applied in positive electrodes, chemical instruments and methods, nickel compounds, etc., can solve the problems of capacity decline, less doping, enrichment of doping elements, etc., to optimize capacity performance and achieve capacity and cycle, the effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

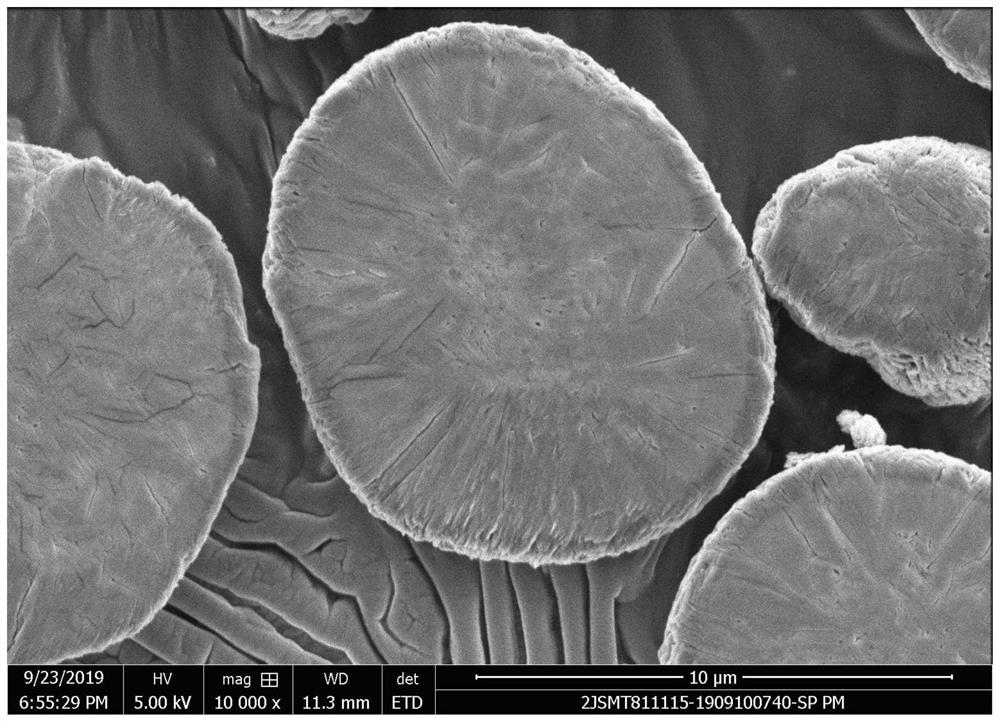

Image

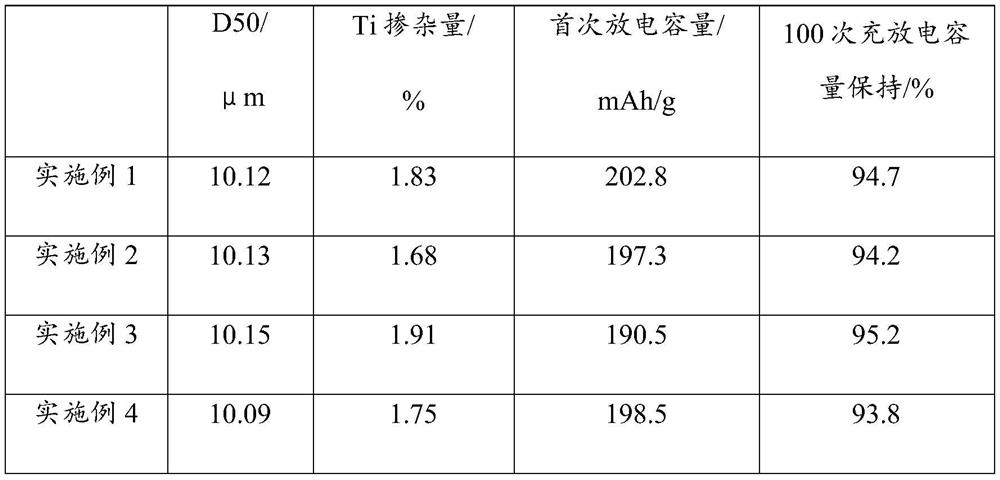

Examples

Embodiment 1

[0023] Step (1): Nickel sulphate, cobalt sulphate, manganese sulphate are formulated into salt solution by nickel ion, cobalt ion, manganese ion mol ratio as 8:1:1, nickel ion, cobalt ion, manganese ion total concentration in the salt solution are 2mol / L. Step (2): Add the salt solution and the precipitating agent sodium hydroxide solution into the reaction kettle to quickly generate a large number of crystal nuclei in the early stage of the reaction, and pump the complexing agent ammonia solution into the reaction kettle at the same time to obtain the inner core as Ni 0.8 co 0.1 mn 0.1 (OH) 2 Particles of nickel-cobalt-manganese ternary precursor. The concentration of sodium hydroxide solution is 2mol / L, and the concentration of ammonia solution is 4mol / L; The feed flow rate that salt solution is added in the reactor is 45L / h, and the feed flow rate that sodium hydroxide solution is added in the reactor is 12L / h h, the flow rate of the ammonia solution pumped into the rea...

Embodiment 2

[0025] Step (1): Nickel sulphate, cobalt sulphate, manganese sulphate are formulated into salt solution by nickel ion, cobalt ion, manganese ion mol ratio as 8:1:1, nickel ion, cobalt ion, manganese ion total concentration in the salt solution are 1mol / L. Step (2): Add the salt solution and the precipitating agent sodium hydroxide solution into the reaction kettle to quickly generate a large number of crystal nuclei in the early stage of the reaction, and pump the complexing agent ammonia solution into the reaction kettle at the same time to obtain the inner core as Ni 0.8 co 0.1 mn 0.1 (OH) 2 Particles of nickel-cobalt-manganese ternary precursor. The concentration of sodium hydroxide solution is 2mol / L, and the concentration of ammonia solution is 4mol / L; The feed flow rate that salt solution is added in the reactor is 60L / h, and the feed flow rate that sodium hydroxide solution is added in the reactor is 18L / h h, the flow rate of the ammonia solution pumped into the rea...

Embodiment 3

[0027] Step (1): Nickel sulphate, cobalt sulphate, manganese sulphate are formulated into salt solution by nickel ion, cobalt ion, manganese ion mol ratio as 8:1:1, nickel ion, cobalt ion, manganese ion total concentration in the salt solution are 3.5mol / L. Step (2): Add the salt solution and the precipitating agent sodium hydroxide solution into the reaction kettle to quickly generate a large number of crystal nuclei in the early stage of the reaction, and pump the complexing agent ammonia solution into the reaction kettle at the same time to obtain the inner core as Ni 0.8 co 0.1 mn 0.1 (OH) 2 Particles of nickel-cobalt-manganese ternary precursor. The concentration of sodium hydroxide solution is 2mol / L, and the concentration of ammonia solution is 4mol / L; The feed flow rate that salt solution is added in the reactor is 30L / h, and the feed flow rate that sodium hydroxide solution is added in the reactor is 7L / h h, the flow rate of the ammonia solution pumped into the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com