Special lubricating grease composition for sintering machine elastic slideways and preparation method thereof

A lubricating grease composition and composition technology, applied in the field of lubricating grease, can solve problems such as poor extreme pressure wear performance, slideway wear, high temperature loss, etc., and achieve the effects of low cost, excellent product performance, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

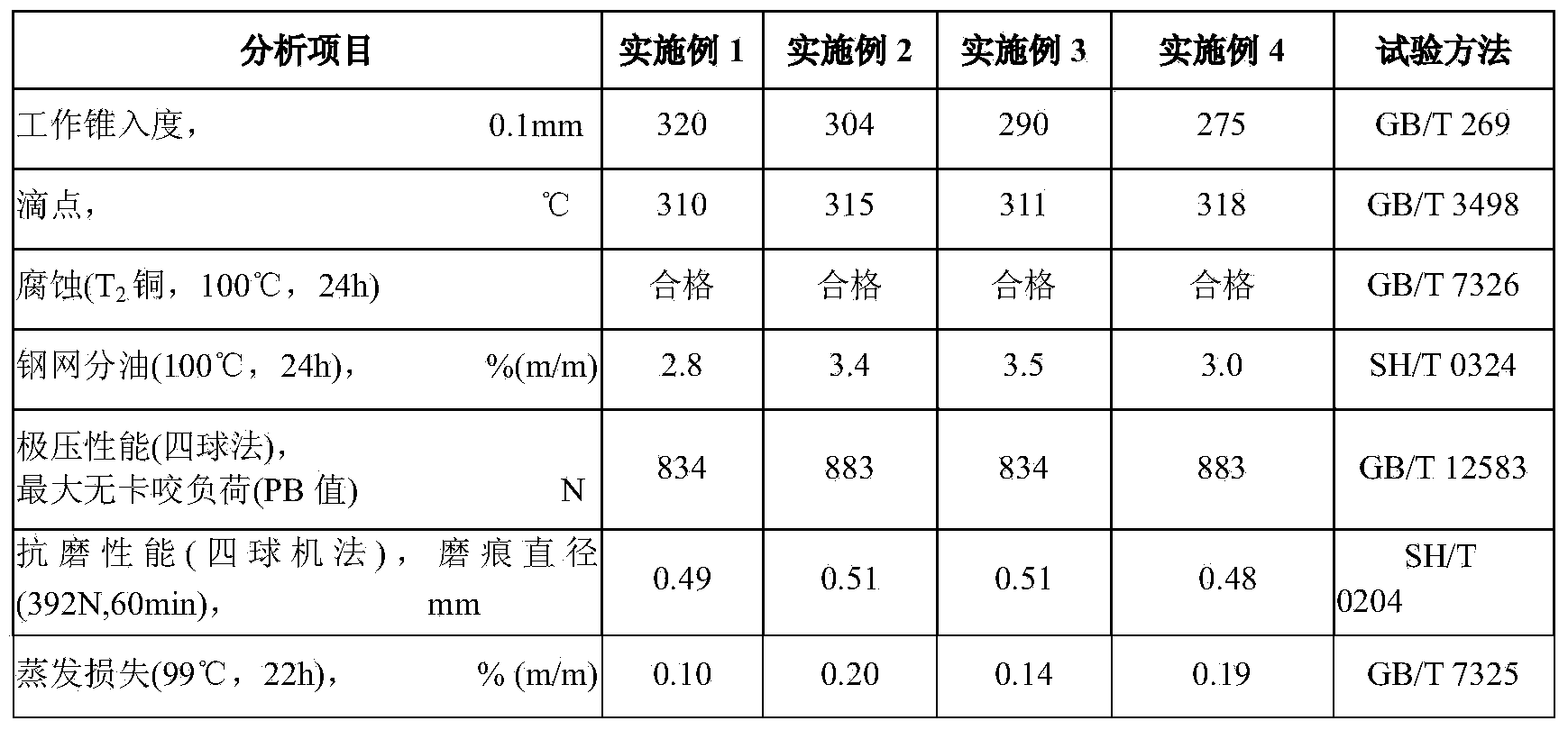

Examples

Embodiment 1

[0023] The material ratio is as follows:

[0024] (1) Thickener 7%

[0025] (2) Base oil 87% (paraffinic lithium series A3 base oil)

[0026] (3) Additive 6%

[0027] The operation steps are:

[0028] (1) Add 150g of 12-hydroxystearic acid and 12.2g of benzoic acid to 1300g of paraffinic lithium series A3 base oil (the kinematic viscosity at 40°C is 120mm 2 / s, 100℃ kinematic viscosity is 12mm 2 / s), heated and stirred to 70°C and dissolved; (2) Dissolved 8.0g lithium hydroxide monohydrate with 35g hot water, added to (1) as a one-step base, controlled the reaction temperature at 90°C, and reacted for 40 minutes; ( 3) Add 30.35g of sebacic acid and stir for 0.5 hours; (4) Dissolve 32.0g of lithium hydroxide monohydrate in 130g of hot water and add slowly as a two-step base. 0.5 hours; (5) raise the temperature to 134-137°C, and keep the temperature constant for 1 hour; (6) add 630g of paraffin-based lithium series A3 base oil, rise to the highest refining temperature of 2...

Embodiment 2

[0030] The material ratio is as follows:

[0031] (1) Thickener 8.9%

[0032] (2) Base oil 85.1% (150BS oil 1100g, PAO 10 synthetic oil 1000g)

[0033] (3) Additive 6%

[0034] The operation steps are:

[0035] (1) Add 180g of 12-hydroxystearic acid and 13.8g of salicylic acid to 1100g of 150BS oil (the kinematic viscosity at 40°C is 600mm 2 / s, 100℃ kinematic viscosity is 32mm 2 / s, freezing point -10°C), heated and stirred to 100°C and dissolved; (2) Dissolved 17.6g of lithium hydroxide monohydrate with 55g of hot water, added to (1) as a one-step base, and reacted for 40 minutes; ( 3) Add 30.35g of sebacic acid and stir for 0.5 hours; (4) Dissolve 26.4g of lithium hydroxide monohydrate in 150g of hot water and add slowly as a two-step base. 0.5 hours; (5) heat up to 130-140°C and keep the temperature constant for 1 hour; (6) add 600g of PAO 10 synthetic oil (the kinematic viscosity at 40°C is 70mm 2 / s, 100℃ kinematic viscosity is 10mm 2 / s) Base oil, raised to the h...

Embodiment 3

[0037] The material ratio is as follows:

[0038] (1) Thickener 9.6%

[0039] (2) Base oil 86.4% (150BS base oil)

[0040] (3) Additive 4%

[0041] The operation steps are:

[0042] (1) Add 142g of stearic acid and 11.6g of boric acid to 1100g of 150BS base oil (the kinematic viscosity at 40°C is 600mm 2 / s, 100℃ kinematic viscosity is 32mm 2 / s, freezing point -10°C), heated and stirred to 90°C and dissolved; (2) Dissolved 30.0g lithium hydroxide monohydrate with 120g hot water, added to (1) as a one-step base, and controlled the reaction temperature to 88~ 98°C, react for 40 minutes; (3) Add 47g of azelaic acid at 95-98°C and stir for 0.5 hours; (4) Dissolve 20.0g of lithium hydroxide monohydrate in 90g of hot water as a two-step base and slowly add The temperature is 100°C, react for 0.5 hours; (5) heat up to 110°C, keep the temperature for 40 minutes; (6) add 480g of 150BS oil, rise to the highest refining temperature of 220°C, keep the temperature for 5-10min, add 300g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com