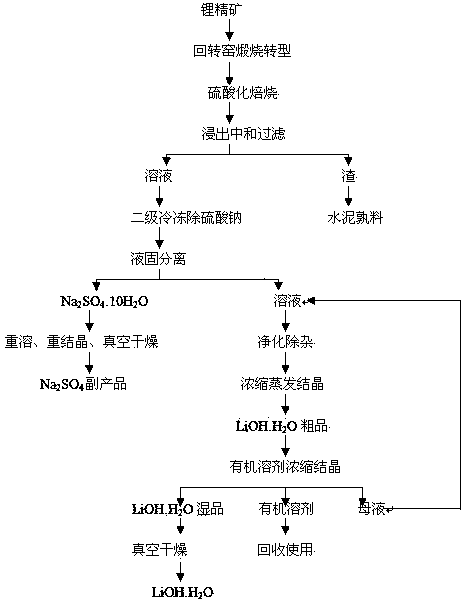

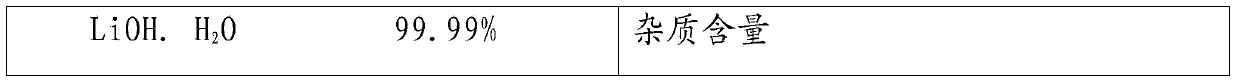

Method for preparing sheet high-purity lithium hydroxide by using spodumene concentrate

A spodumene concentrate, lithium hydroxide technology, applied in the direction of lithium oxide;/hydroxide, can solve the problems of unsatisfactory crystal particle size distribution, low degree of automation, low light transmittance, etc., and achieve particle distribution Narrow and easy to control, improve labor efficiency, stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A spodumene concentrate in China, Li in the concentrate 2 The mass percentage content of O is 5.2%, and the spodumene concentrate is ground, when the particle size above -200 mesh accounts for 80% of the total content, and the Li-containing recovered from the kiln head 2O dust is mixed and added from the kiln head, and the -200 mesh coal powder is sprayed into the burning rotary kiln by a controllable movable coal injection pipe at the kiln tail. The temperature in the high temperature zone of the rotary kiln is controlled at 950°C, and the length of the high temperature zone is controlled At 12m, the residence time in the high temperature zone is 22min. The calcined material from the kiln tail is cooled to 40°C, and then enters the ball mill for ball milling to -200 mesh to reach 80% of the total mass content. The whole process is automatically controlled.

[0031] The finely ground ore containing βLi is mixed with anthracic sulfuric acid. The added mass of sulfuric ac...

Embodiment 2

[0039] Overseas Australian mine spodumene concentrate, of which Li 2 The mass percent content of O is 6.13%, and the spodumene concentrate is ground to -180 mesh to reach more than 80% of the total content, and the recovery rate of Li from the kiln head 2 The dust mixed with O is fed from the kiln head by the screw feeder, and the coal powder pulverized to -200 mesh is sprayed into the burning rotary kiln by the controllable moving coal injection pipe at the kiln tail. The temperature in the high temperature zone is 1100 °C , the length of the high-temperature zone is controlled at 13.5M, the residence time of the material in the high-temperature zone is 25min, the calcined material from the kiln tail is cooled to <40°C, and then enters the ball mill for ball milling to -200 mesh to reach about 80% of the total content. All automatic control.

[0040] The finely ground minerals containing βli are mixed with anthracite sulfuric acid. The amount of sulfuric acid added is Wt135%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com