Method for preparing lithium lubricating grease

A lithium-based grease, the technology of lubricating grease, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of waste, dehydration time and energy consumption increase, and achieve the effect of reducing energy consumption and widening development space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

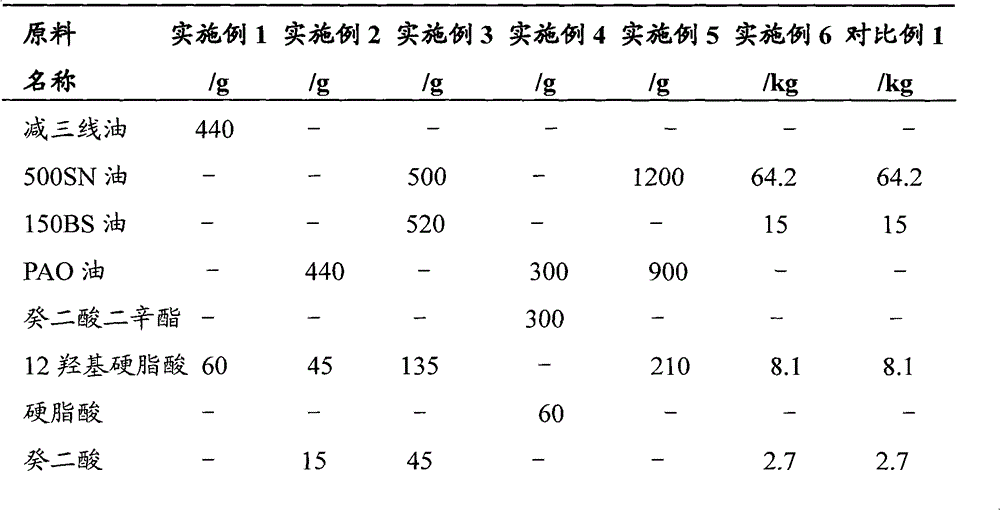

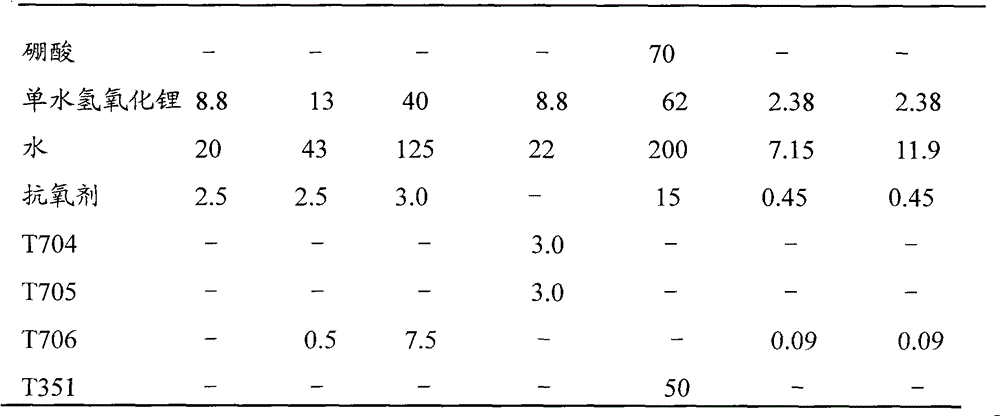

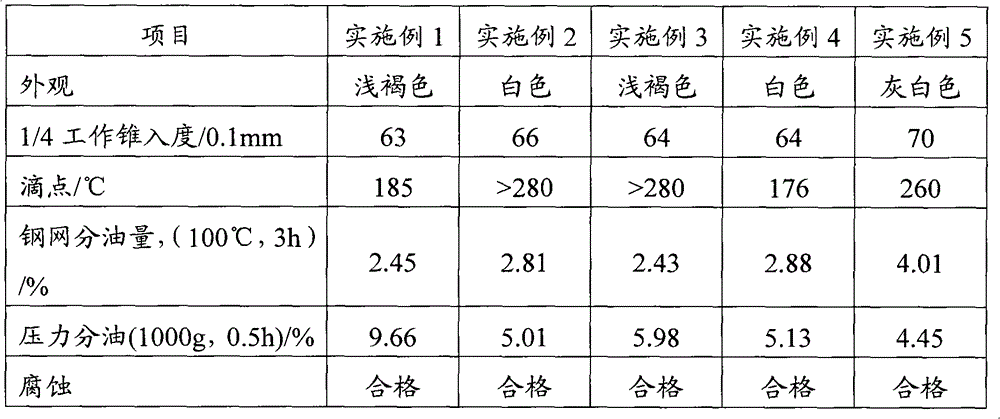

Embodiment 1

[0018] 250g reduced third-line base oil (100℃ viscosity 8.555mm 2 / s) Add 60g of 12-hydroxystearic acid to the fat making kettle, heat up and stir evenly; add 4.4g of lithium hydroxide monohydrate crystals at 60℃, mix well, add lithium hydroxide solution at 85℃ (dissolve in 20g of water) 4.4g lithium hydroxide), proceed with the reaction; continue heating and dehydration, after the water has evaporated, continue heating to 210°C, add 190g of reduced third-line quenching oil, start cooling, and cool to 120°C, add 2.5g of 2,6 di-tert-butyl Based on p-cresol antioxidant, mix well and grind three times to obtain the finished lubricating grease. The physical and chemical performance data are shown in Table 2.

Embodiment 2

[0020] 200g PAO base oil (100℃ viscosity 6.128mm 2 / s) Add to the fat making kettle, then add 45g of 12 hydroxystearic acid and 15g of sebacic acid, heat up and stir evenly; add 5g of lithium hydroxide monohydrate crystals at 70°C, mix well, and add hydrogen dropwise at 93°C Lithium solution (8g lithium hydroxide dissolved in 43g water), proceed with the reaction; continue heating and dehydration, after the water evaporates, continue heating to 210°C, add 240g of PAO quench oil, start cooling, and add 2.5g of diphenylamine to 120°C Antioxidant and 0.5g of T706 rust inhibitor were mixed evenly and ground three times to obtain the finished lubricating grease. The physical and chemical performance data are shown in Table 2.

Embodiment 3

[0022] 800g 500SN base oil (100℃ viscosity 10.566mm 2 / s) Add to the fat making kettle, then add 135g of 12 hydroxystearic acid and 45g of sebacic acid, heat up and stir evenly; add 15g of lithium hydroxide monohydrate crystals at 70°C, mix well, and add hydrogen dropwise at 90°C Lithium solution (25g lithium hydroxide dissolved in 125g water), proceed to the reaction; continue to heat up the dehydration, after the water has evaporated, continue to heat up to 210°C, add 520g of 150BS (100°C viscosity 31.584mm) 2 / s) Quickly cool the oil, start to cool down, add 30g of diisooctyldiphenylamine antioxidant and 7.5g of T706 rust inhibitor, mix well, grind three times to obtain the finished grease, see the physical and chemical performance data Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com