Waste heat recovery device for billets produced by continuous casting machine

A waste heat recovery device and recovery device technology, applied in the metallurgical industry, can solve problems such as waste heat waste and deterioration of the working environment, and achieve the effects of improving the environment, improving the working environment, and reducing the use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with the accompanying drawings.

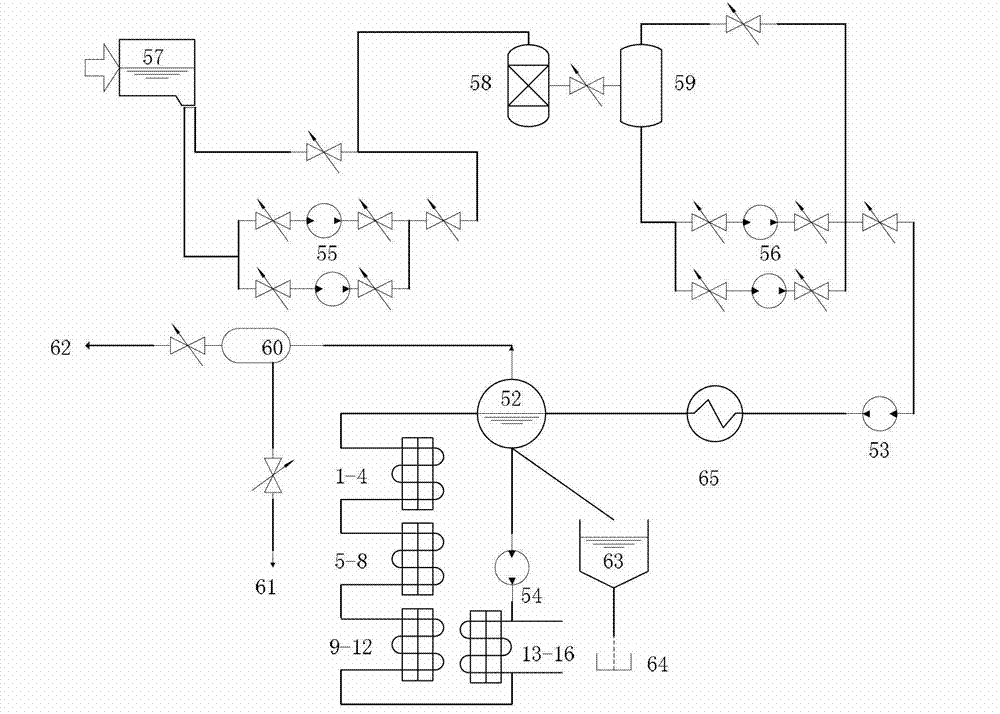

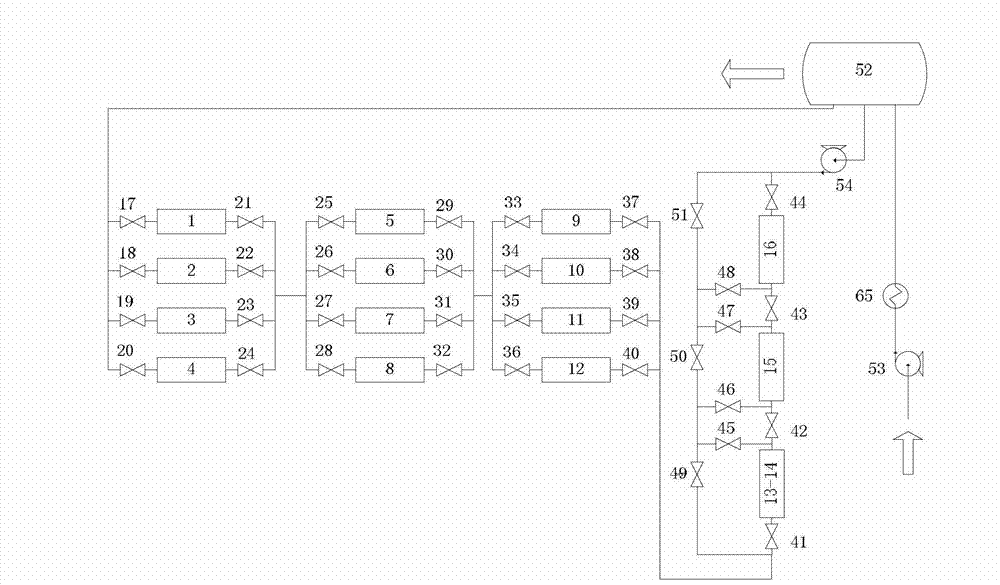

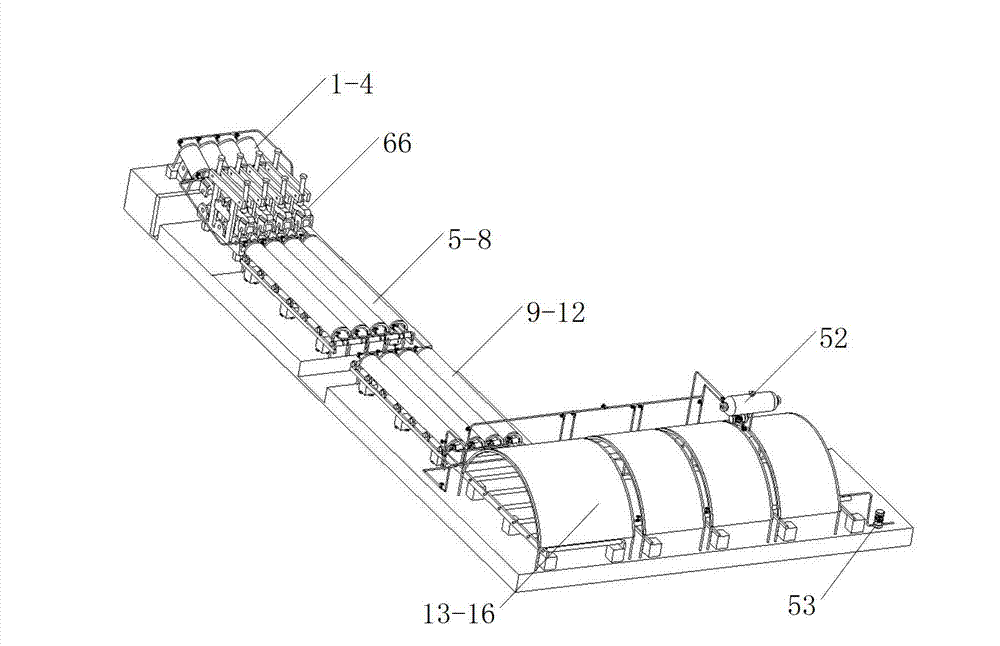

[0026] image 3 and Figure 4 It is the overall oblique view of the billet waste heat recovery device. The feed water enters the preheater 65 through the feed water pump 53 for preheating and then enters the steam-water separator 52. In the steam-water separator, liquid water and steam pass through the steam-water cyclone separator, the corrugated plate separator and gravity separation After that, it enters the downcomer and is pressurized by the forced circulation pump, and then enters the radiant heating surface 13-16 of the pusher section, the radiant heating surface 9-12 of the rear cutting section, the radiative heating surface 5-8 of the front section of the cutting section, and the front section of the drawing machine The radiant heating surfaces 1-4 then return to the steam separator. After the billet leaves the continuous casting machine, it is drawn and for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com