HRB600E reinforcement steel bar and production method thereof

A production method and steel bar technology, applied in the field of HRB600E steel bar and its production, can solve the problems of waste of alloy elements, not too many, etc., and achieve the effects of low cost, reduced production cost, and high yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

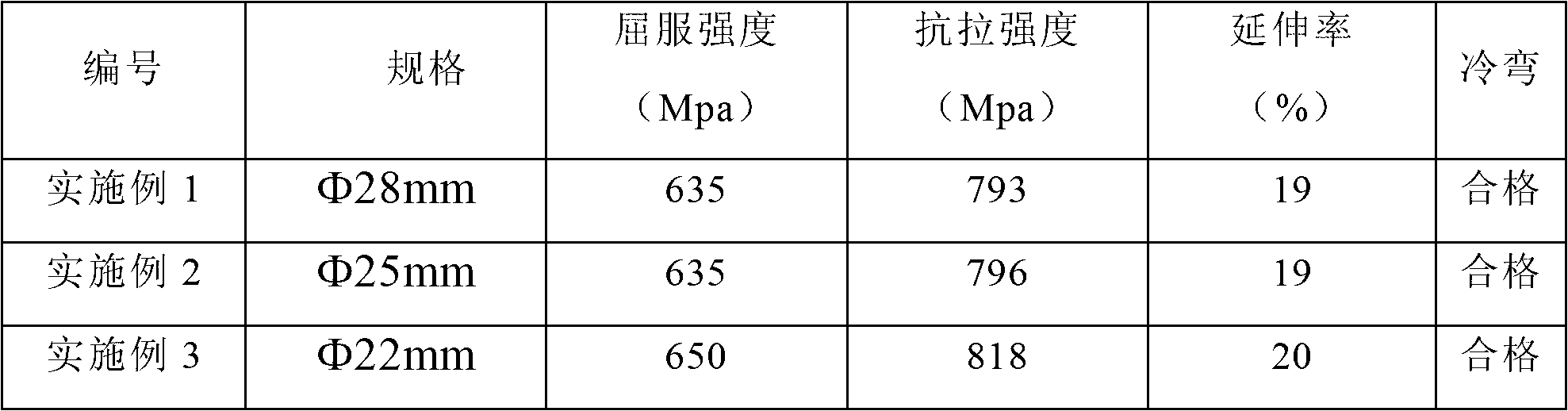

Examples

Embodiment 1

[0029] The method for producing the HRB600E seismic steel bar includes a smelting process, a continuous casting process and a steel rolling process. The specific steps of each process will be described below.

[0030] In the smelting process, the converter or electric furnace is used to smelt molten steel and alloy the ladle. In the ladle alloying step, in addition to adding silicon-manganese and ferrosilicon alloys, ferrochromium alloys and vanadium-nitrogen alloys are also added, so that the Cr content in the molten steel composition reaches 0.032%, and the V content reaches 0.12%.

[0031] In the continuous casting process, the billet is casted by a continuous casting machine to form a 150mm×150mm square billet, and the billet casting speed is 2.1m / min.

[0032] In the steel rolling process, the billet is rolled at the start rolling temperature of 1070°C, and rolled at the finish rolling temperature of 860°C, and is naturally cooled on the cooling bed after rolling. The H...

Embodiment 2

[0034]The method for producing the HRB600E seismic steel bar includes a smelting process, a continuous casting process and a steel rolling process. The specific steps of each process will be described below.

[0035] In the smelting process, the converter or electric furnace is used to smelt molten steel and alloy the ladle. In the ladle alloying step, in addition to adding silicon-manganese and ferrosilicon alloys, ferrochrome and vanadium-nitrogen alloys are also added, so that the Cr content in the molten steel composition reaches 0.030%, and the V content reaches 0.11%. Afterwards, the molten steel is refined through the LF refining furnace and the VD vacuum degassing furnace in turn.

[0036] In the continuous casting process, the billet is casted by a continuous casting machine to form a 150 mm×150 mm square billet, and the billet casting speed is 2.0 m / min.

[0037] In the steel rolling process, the billet is rolled at the start rolling temperature of 1050°C, and roll...

Embodiment 3

[0039] The method for producing the HRB600E seismic steel bar includes a smelting process, a continuous casting process and a steel rolling process. The specific steps of each process will be described below.

[0040] In the smelting process, the converter or electric furnace is used to smelt molten steel and alloy the ladle. In the ladle alloying step, in addition to adding silicon-manganese and ferrosilicon alloys, ferrochromium alloys and vanadium-nitrogen alloys are also added, so that the Cr content in the molten steel composition reaches 0.028%, and the V content reaches 0.10%. Afterwards, the molten steel is refined through the LF refining furnace and the VD vacuum degassing furnace in turn.

[0041] In the continuous casting process, the billet is casted by a continuous casting machine to form a 150mm×150mm billet, and the billet casting speed is 2.1m / min.

[0042] In the steel rolling process, the billet is rolled at the start rolling temperature of 1030°C, and roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| strong bend ratio | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com