Flexographic plate water-based ink for high-speed printing and preparation method thereof

A water-based ink, high-speed printing technology, applied in ink, household utensils, applications, etc., can solve the problems of being unable to adapt to high-speed flexographic printing, and achieve excellent leveling and overprinting effects, fast drying speed, and high color saturation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

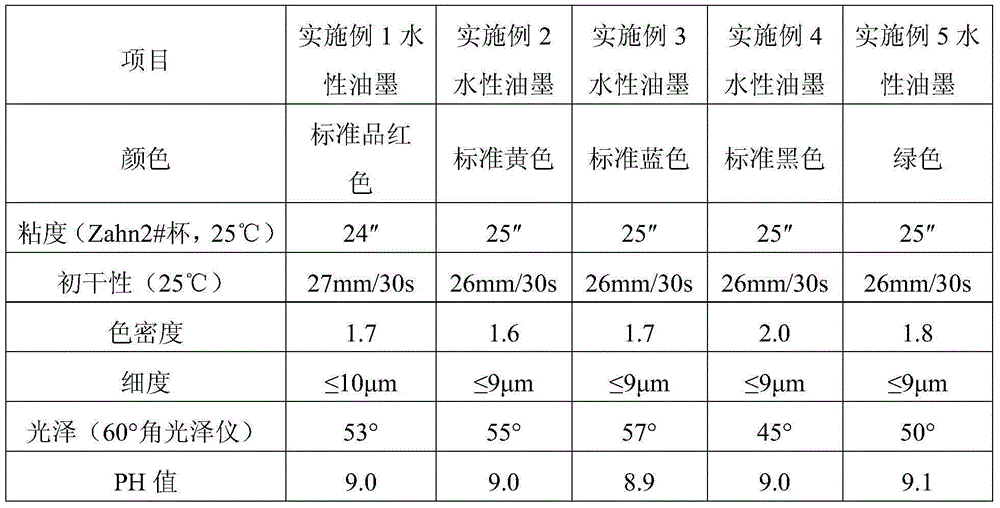

Examples

Embodiment 1

[0029] The flexographic water-based ink of the high-speed printing of the present embodiment consists of the following components by weight: 32.9 parts of acrylic non-film-forming emulsion, 5 parts of acrylic film-forming emulsion, 15 parts of acrylic resin solution A, 39 parts of water-based color paste, polyethylene 1.5 parts of wax, 1 part of film-forming aid, 0.3 part of leveling agent, 0.1 part of defoamer, 0.2 part of pH regulator and 5 parts of deionized water.

[0030] Among the above-mentioned flexographic water-based inks:

[0031] Acrylic non-film-forming emulsion adopts acrylic emulsion BasfJoncryl89, its solid content is 48%, Tg value is 98°C, acid value is 50mgKOH / g, pH value is 8.3; acrylic film-forming emulsion adopts acrylic emulsion BasfJoncryl77, its solid content is 46% , the Tg value is 21°C, the acid value is 55mgKOH / g, and the pH value is 8.3; the polyethylene wax is specifically polyethylene wax MD-2000; the film-forming aid is specifically propylene gl...

Embodiment 2

[0043] The flexographic water-based ink of the high-speed printing of the present embodiment is made up of the following components by weight: 34.7 parts of acrylic acid film-forming emulsion, 5 parts of acrylic acid film-forming emulsion, 18 parts of acrylic resin solution A, 35 parts of water-based color paste, polyethylene 1 part of wax, 1.5 parts of film-forming aid, 0.5 part of leveling agent, 0.1 part of defoamer, 0.2 part of pH regulator and 4 parts of deionized water; except for water-based color paste, other components are the same as in Example 1.

[0044] The water-based color paste is composed of the following components by weight: 45 parts of yellow pigment (PY14), 26 parts of acrylic resin solution B, 28.4 parts of deionized water, 1.5 parts of wetting and dispersing agent (TEGOdispersers760) and 0.1 parts of defoamer BYK0930; Wherein: acrylic resin solution B is the same as Example 1.

[0045] Above-mentioned flexographic water-based ink can be prepared by the f...

Embodiment 3

[0051] The flexographic water-based ink of the high-speed printing of the present embodiment consists of the following components by weight: 35 parts of acrylic non-film-forming emulsion, 6 parts of acrylic film-forming emulsion, 17 parts of acrylic resin solution A, 35 parts of water-based color paste, polyethylene 1 part of wax, 1 part of film-forming aid, 0.5 part of leveling agent, 0.1 part of defoamer, 0.2 part of pH regulator and 4.2 parts of deionized water.

[0052] Among the above-mentioned flexographic water-based inks:

[0053] Acrylic non-film-forming emulsion uses acrylic emulsion IndulorSE900; acrylic film-forming emulsion uses acrylic emulsion IndulorSE2872; polyethylene wax is specifically polyethylene wax AQUAACER552; film-forming aid is specifically butyl carbitol; leveling agent is specifically SURFYNOL420; defoaming The agent is specifically TEGO1488; the pH regulator is specifically AMP-95; they are all commercially available.

[0054] Acrylic resin solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Tg value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com