Rare earth oxide-containing steelmaking refining slag, and preparation method and using method thereof

A rare earth oxide and refining slag technology, applied in the field of steelmaking and refining, can solve the problems of unfavorable inclusion absorption and fluidity deterioration, and achieve the effects of good fluidity, low melting temperature and rich slagging resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 200Kg induction furnace melting. The operation steps are as follows: (1) Add 160Kg of high-quality low-carbon scrap steel, and melt it with electricity; (2) When the melting is completed, the temperature is 1580°C, add ferromanganese and ferrosilicon for alloying; (3) Use an oxygen meter to measure the steel Active oxygen in the liquid, 150-200ppm; (4) Then add the refining slag CaO 52-58%, Al 2 o 3 22~30%, MgO 3~8%, SiO 2 4~12%, CaF 2 1 to 3%; (5) After 3 to 5 minutes, after the slag (primary slag) has been melted, add cerium oxide and other slag-forming materials, wait until the slag is completely melted evenly, and control the electric parameters of the induction furnace. The slag is well covered on the liquid steel surface, and the obtained new slag components are controlled within the scope of the present invention: CaO 50-55%, Al 2 o 3 20-25%, Ce 2 o 3 4~8%, MgO 3~6%, SiO 2 8~10%, CaF 2 1.5~4%, the total slag amount is 35Kg; (6) insert aluminum bar...

Embodiment 2

[0036] 200Kg induction furnace melting. The operation steps are as follows: (1) Add 160Kg of high-quality low-carbon scrap steel, and melt it with electricity; (2) When the melting is completed, the temperature is 1580°C, add ferromanganese and ferrosilicon for alloying; (3) Use an oxygen meter to measure the steel Active oxygen in the liquid, 150-200ppm; (4) remove the surface residue produced in the smelting process; (5) then add 35Kg of the pre-melted refining slag of the present invention, the slag composition is: CaO 45-52%, Al 2 o 3 12~25%, Ce 2 o 3 3~16%, MgO 3~6%, SiO 2 8~10%, CaF 2 1.5 to 4%; (6) After 3 to 5 minutes, the slag has been melted, and the electric parameters of the induction furnace are well controlled so that the added refining slag covers the liquid steel surface; (7) Insert an aluminum rod in the middle so that the acid-soluble aluminum content in the molten steel is controlled at 0.015-0.035%, and the molten steel is sampled after 1-2 minutes...

Embodiment 3

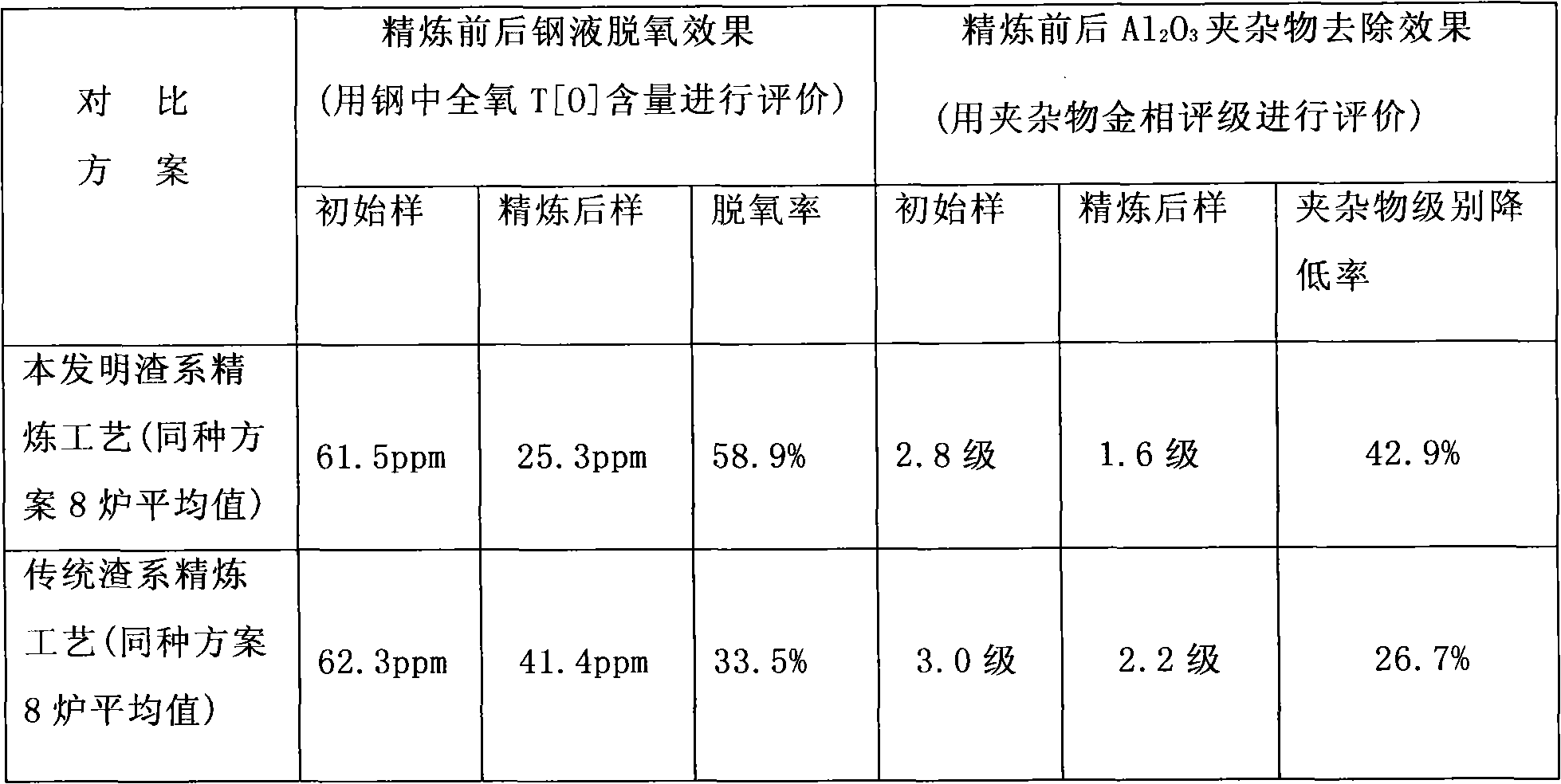

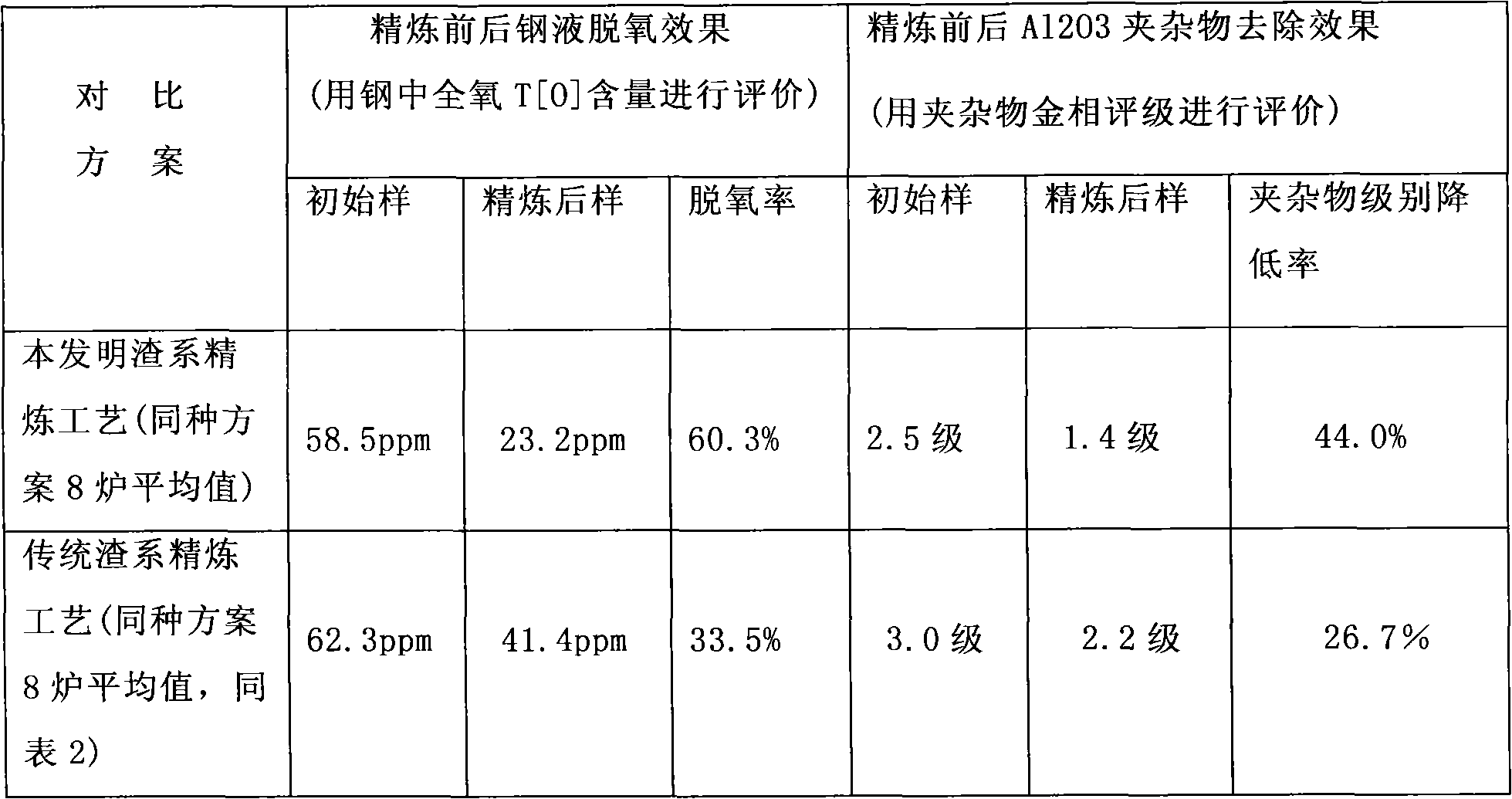

[0041]The experiment was carried out on a 100-ton top-blown oxygen converter. The test steps are as follows: (1) The converter uses 85% molten iron, and adds 15% scrap steel for blowing, and taps after completing decarburization, dephosphorization and end temperature control tasks; (2) Tapping should strictly control the slag, After tapping, the amount of slag in the ladle is less than 80mm; (3) The ladle is transported to the refining station of the LF furnace, and then lime and other slagging materials are added to deoxidize the molten steel with aluminum, and the slag is deoxidized with aluminum particles, silicon carbide, calcium carbide, etc. agent to make the FeO content in the slag less than 1.0%, the slag turns white, and the slag composition meets the requirements of CaO 52-58%, Al 2 o 3 22~30%, MgO 3~8%, SiO 2 4~12%, CaF 2 1 to 3%, so that the content of acid-soluble aluminum in the molten steel is controlled at 0.015 to 0.035%, and the molten steel is sampled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com