Oil well cement and production method thereof

An oil well cement and production method technology, applied in the direction of cement production and the like, can solve problems such as oil well cement reports that have not yet been reported, and achieve the effects of reducing resource consumption, reducing environmental load, and good homogenization of raw meal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

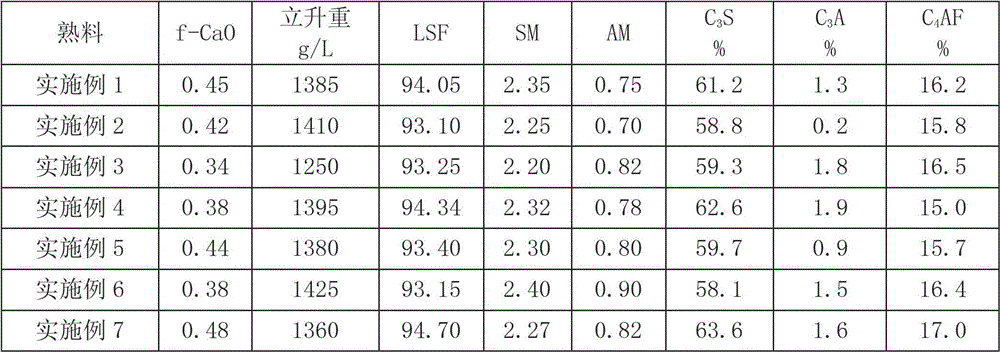

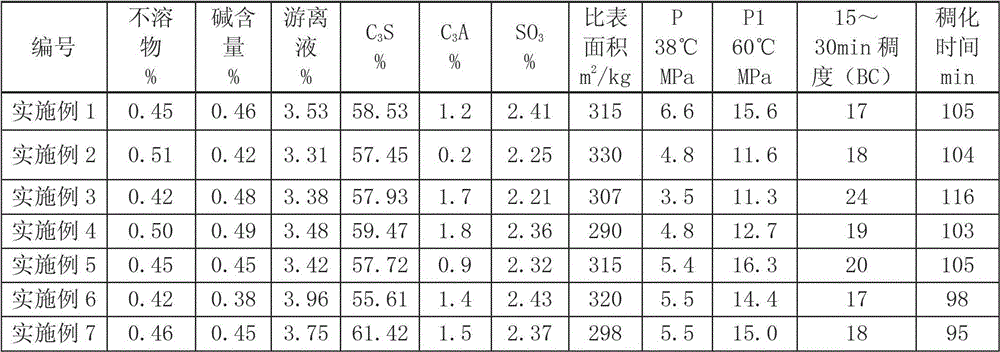

Examples

Embodiment 1

[0034] 1. Raw meal preparation: The raw meal is weighed according to the following weight percentages: limestone 78%, sandstone 15%, converter slag 7%, wet grinding process is adopted, and the raw material into the mill is mixed with a certain proportion of water to pass through ball mill grinding Slurry, pump the slurry into the 8 slurry storages of the slurry pump system. The slurry is accurately dosed, put into the slurry mixing tank, and enter the slurry filtration system through the uniform batching pump. Stir evenly to make a 35% slurry ;

[0035] 2. Slurry dehydration: dehydrate the above slurry with a vacuum suction filter to form a filter cake with a water content of 17%, and the filter cake falls to the conveyor belt with BMP;

[0036] 3. Filter cake drying and crushing: the filter cake is fed into the drying crusher through the box feeder, and the hot exhaust gas (600°C) from the kiln tail will dry it into raw meal powder with a water content of 3%. The dried exhau...

Embodiment 2

[0040]1. Raw meal preparation: The raw meal is weighed according to the following weight percentages: 82% limestone, 9% sandstone, and 9% converter slag. The wet grinding process is adopted, and the raw materials are mixed with a certain proportion of water to pass through ball mill grinding. Slurry, pump the slurry into the 8 slurry storages of the slurry pump system. The slurry is accurately dosed, put into the slurry mixing tank, and enter the slurry filtration system through the uniform batching pump. Stir evenly to make a 37% slurry ;

[0041] 2. Slurry dehydration: dehydrate the above slurry with a vacuum suction filter to form a filter cake with a water content of 18%, and the filter cake falls to the conveyor belt with BMP;

[0042] 3. Filter cake drying and crushing: the filter cake is fed into the drying crusher through a box feeder, and the hot exhaust gas (600°C) from the kiln tail is dried to raw meal powder with a water content of 2%. The dried exhaust gas is br...

Embodiment 3

[0046] 1. Raw meal preparation: The raw meal is weighed according to the following weight percentages: 76% limestone, 18% sandstone, and 6% converter slag. The wet grinding process is adopted, and the raw materials are mixed with a certain proportion of water to pass through ball mill grinding. Slurry, pump the slurry into the 8 slurry storages of the slurry pump system. The slurry is accurately dosed, put into the slurry mixing tank, and enter the slurry filtration system through the uniform batching pump. Stir evenly to make a 34% slurry ;

[0047] 2. Slurry dehydration: dehydrate the above slurry with a vacuum suction filter to form a filter cake with a water content of 18%, and the filter cake falls to the conveyor belt with BMP;

[0048] 3. Filter cake drying and crushing: the filter cake is fed into the drying crusher through the box feeder, and the hot exhaust gas (600°C) from the kiln tail will dry it into raw meal powder with a water content of 1%. The dried exhaust ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com