Oil tea fruit unshelling separator

A technology of camellia fruit and sorting machine, which is applied in the directions of shelling, oil/fat production, and fat production, etc., can solve the problems of not being able to sort fruit shells and tea seeds well, squeezing into outer cages, and inconvenient to use, etc. , to achieve the effect of light structure, low power consumption and reduction of crushing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

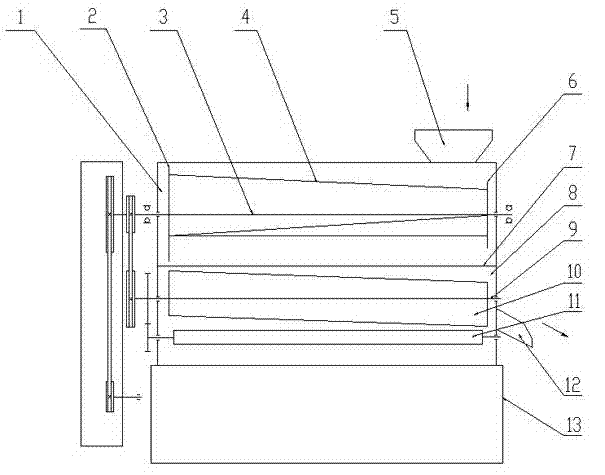

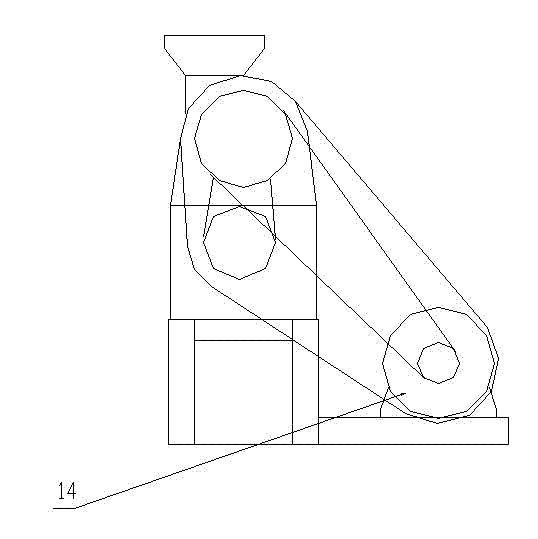

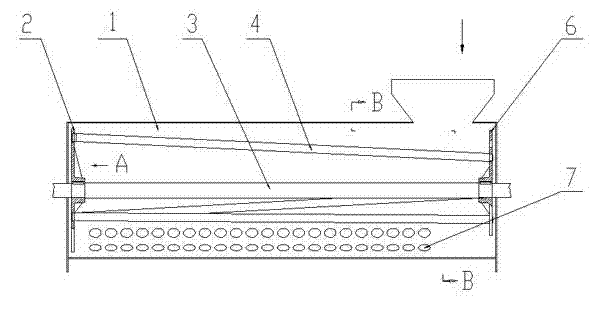

[0027] Camellia oleifera shelling and sorting machine consists of a feed hopper 5, a shelling drum part, a shell and tea seed sorting part, a power transmission part 14, and a frame 13. The shelling drum part is located in the shell and tea seed sorting part. Above the parts, it is installed on the frame 13 together with the fruit shell and tea seed sorting parts, and the feeding hopper 5 is installed above the shelling drum part, and the power transmission part 14 is sequentially connected with the shelling drum parts, fruit shells and tea seeds through the belt. The sorting parts are connected; the shelling drum parts are composed of a shelling drum 1, a large shelling disc 2, a main shaft 3, a shelling rod 4, a small shelling disc 6 and a screen 7, and the large shelling disc 2 is connected with the small shelling disc. Three shelling rods 4 are installed between the shell plates 6, and the large shelling plate 2 and the small shelling plate 6 are staggered by 20 in the left...

Embodiment 2

[0033]Camellia oleifera shelling and sorting machine consists of a feed hopper 5, a shelling drum part, a shell and tea seed sorting part, a power transmission part 14, and a frame 13. The shelling drum part is located in the shell and tea seed sorting part. Above the parts, it is installed on the frame 13 together with the fruit shell and tea seed sorting parts, and the feeding hopper 5 is installed above the shelling drum part, and the power transmission part 14 is sequentially connected with the shelling drum parts, fruit shells and tea seeds through the belt. The sorting parts are connected; the shelling drum parts are composed of a shelling drum 1, a large shelling disc 2, a main shaft 3, a shelling rod 4, a small shelling disc 6 and a screen 7, and the large shelling disc 2 is connected with the small shelling disc. Three shelling rods 4 are installed between the shell plates 6, and the large shelling plate 2 and the small shelling plate 6 are staggered by 30 degrees in t...

Embodiment 3

[0038] Camellia oleifera shelling and sorting machine consists of a feed hopper 5, a shelling drum part, a shell and tea seed sorting part, a power transmission part 14, and a frame 13. The shelling drum part is located in the shell and tea seed sorting part. Above the parts, it is installed on the frame 13 together with the fruit shell and tea seed sorting parts, and the feeding hopper 5 is installed above the shelling drum part, and the power transmission part 14 is sequentially connected with the shelling drum parts, fruit shells and tea seeds through the belt. The sorting parts are connected; the shelling drum parts are composed of a shelling drum 1, a large shelling disc 2, a main shaft 3, a shelling rod 4, a small shelling disc 6 and a screen 7, and the large shelling disc 2 is connected with the small shelling disc. Three shelling rods 4 are installed between the shell plates 6, and the large shelling plate 2 and the small shelling plate 6 are staggered by 35 degrees in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com