Spice nano-microcapsule and preparation method thereof

A spice, nano-technology, applied in the direction of essential oil/spice, fat production, etc., can solve the problems of poor dispersion and uniformity, poor dispersion, etc., and achieve the effects of stable product properties, good dispersibility and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

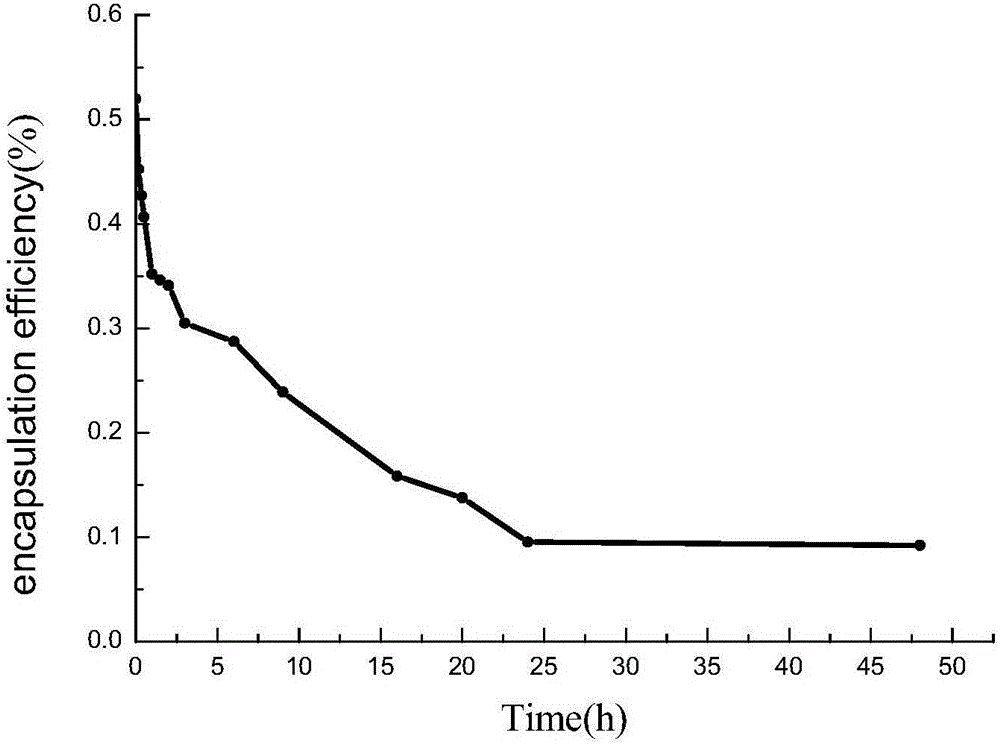

[0030] Table 1 Embedding rate and loading capacity of microcapsules

[0031] sample number 1 2 3 4 5 6 average value Embedding rate / % 51.6 52.0 51.6 51.7 51.8 51.9 51.8 Loading / % 24.9 25.1 24.9 25.0 25.0 25.1 25.0

Embodiment 2

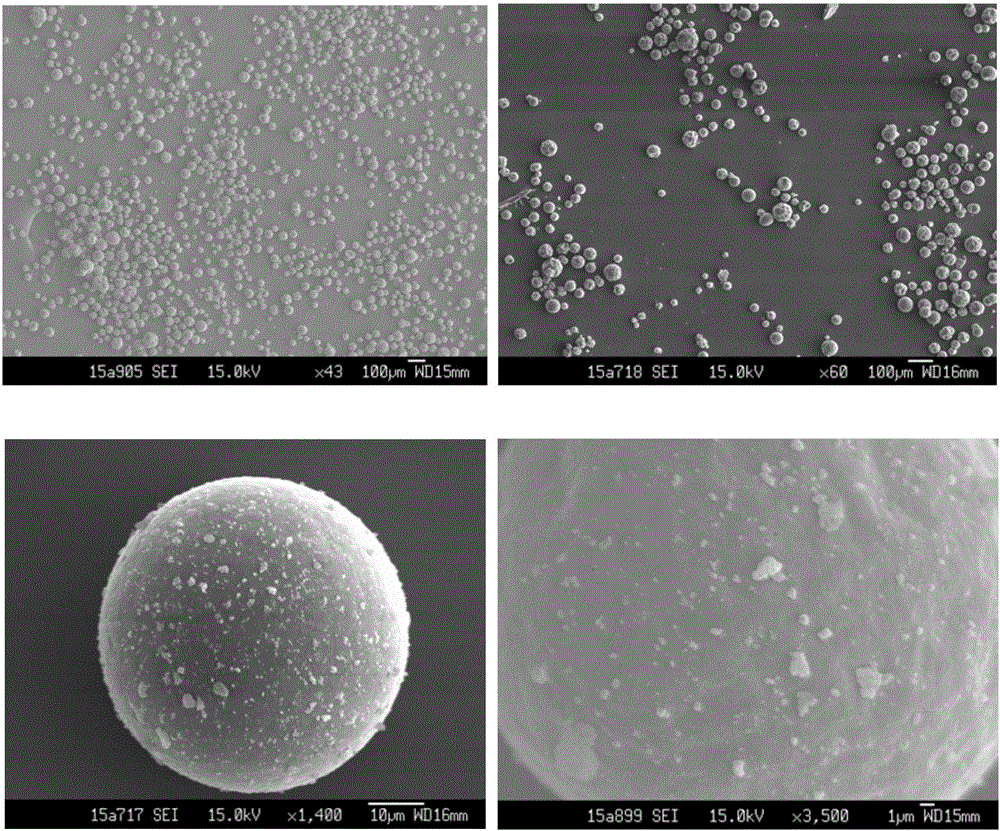

[0033] Take a clean 250mL beaker, add about 200mL of water, bathe in water to 55℃, then add 5.0g of sodium caseinate, 30.0g of modified starch, 20.0g of maltodextrin, 10.0g of β-cyclodextrin, and 10.0g of gum arabic , glucose 4.0g, constant temperature mixing and stirring to dissolve. Use dipotassium hydrogen phosphate, citric acid, and anhydrous sodium carbonate to adjust the pH to about 7, then add 5.0 g of sucrose ester and 50.0 g of rose essential oil, and the concentration of the prepared solution is about 30%. Wall material: core material = 7:5, gum arabic: sodium caseinate: modified starch: maltodextrin: β-CD: glucose = 7%:7%:28%:42%:7%:7%, in The number of revolutions is 8000r / min, high-speed shearing is carried out for 15 minutes, and the membrane emulsifier with a membrane tube of 5.2 μm is emulsified 5 times to obtain a microcapsule emulsion, and then the emulsion is spray-dried, and the spray dryer is set at an inlet temperature of 200 °C, the outlet temperature i...

Embodiment 3

[0035]Take a clean 250mL beaker, add about 200mL of water, bathe in water to 55°C, then add 5.0g of sodium caseinate, 30.0g of modified starch, 20.0g of maltodextrin, 5.0g of β-cyclodextrin, and 5.0g of gum arabic , Glucose 10.0g, constant temperature mixing and stirring to dissolve. Use dipotassium hydrogen phosphate, citric acid, and anhydrous sodium carbonate to adjust the pH to about 7, then add 5.0 g of sucrose ester and 50.0 g of tea tree essential oil, and the concentration of the prepared solution is about 30%. Wall material: core material = 7:5, gum arabic: sodium caseinate: modified starch: maltodextrin: β-CD: glucose = 7%:7%:28%:42%:7%:7%, in The number of revolutions is 8000r / min, high-speed shearing is carried out for 15 minutes, and the membrane emulsifier with a membrane tube of 5.2 μm is emulsified 5 times to obtain a microcapsule emulsion, and then the emulsion is spray-dried, and the spray dryer is set at an inlet temperature of 200 °C, the outlet temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com