Preparation method of monodisperse large size carbon ball

A large-scale, monodisperse technology, used in the chemical industry, can solve the problems of no way to prepare porous carbon spheres, increase the preparation cost, and complex processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

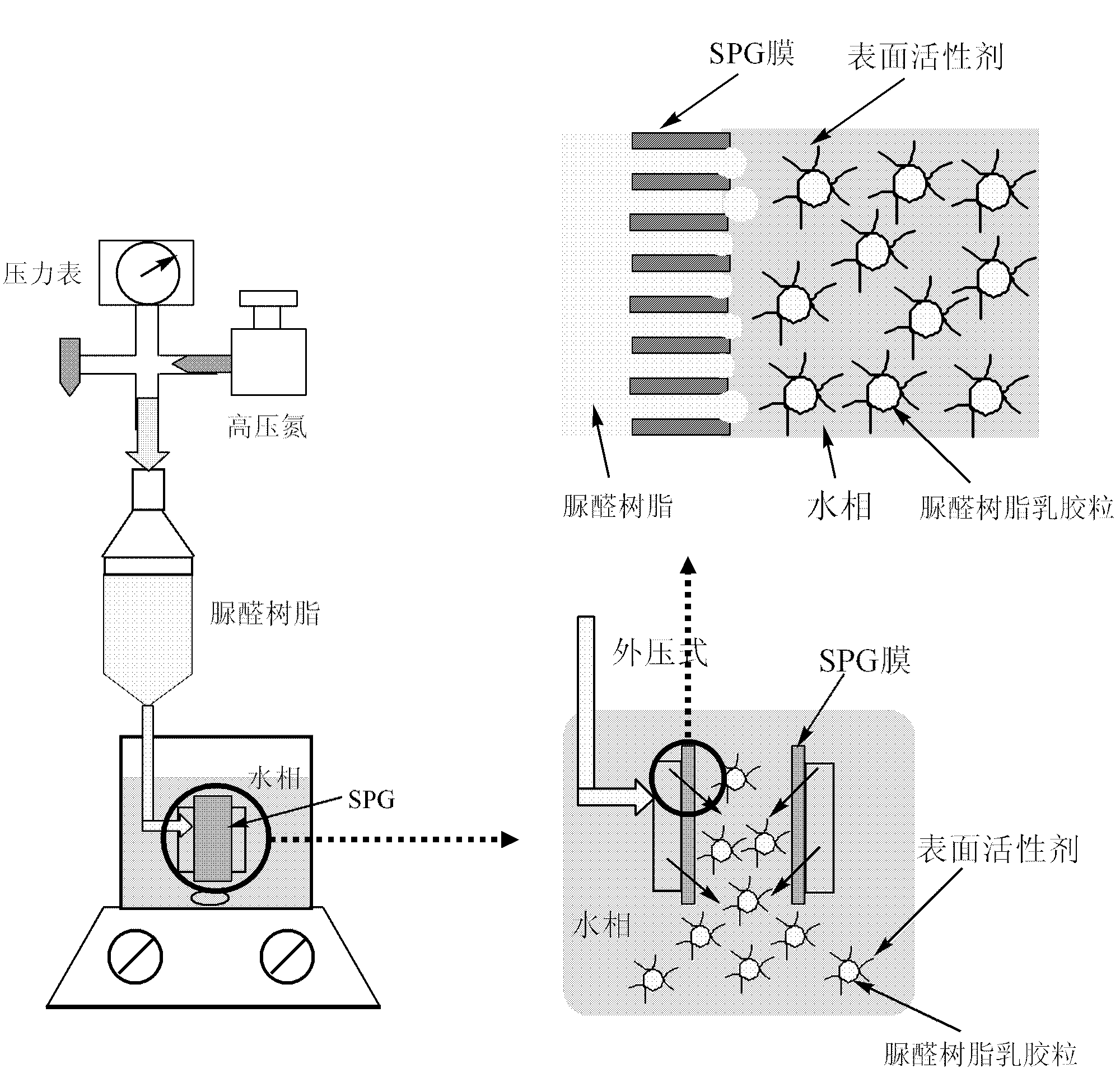

[0022] The model of the external pressure SPG membrane emulsifier is MG-20, and the specification of the SPG membrane is Φ10×L20mm. Add 8g of liquid urea-formaldehyde resin as a carbon source into the oil tank of the SPG emulsifier. The liquid urea-formaldehyde resin used must meet the following two conditions: (1) The viscosity at room temperature is between 150 and 1200cps, and the pressure is 0.2-0.5 MPa It can be extruded from the hole of the glass membrane of the emulsifier smoothly; (2) The resin can be further cross-linked and solidified. The concentration of sodium dodecyl sulfonate in the water phase is 0.5wt%, the concentration of ammonium chloride is 0.2mol / L, and the concentration of PVA is 0.1wt%; Adjust the nitrogen valve to make the pressure in the oil phase reach 0.20MPa. Under the action of pressure, the hydrophobic liquid urea-formaldehyde resin is pressed into the water phase through the pores of the glass membrane to obtain oil droplets of uniform size; at ...

example 2

[0024] The model of the external pressure SPG membrane emulsifier is MG-20, and the specification of the SPG membrane is Φ10×L20mm. In the oil tank of SPG emulsifier, add 8g liquid urea-formaldehyde resin as carbon source, the condition that liquid urea-formaldehyde resin used needs to satisfy is the same as example 1. The concentration of AEO-9 in the water phase is 0.3wt%, the concentration of ammonium chloride is 0.1mol / L, and the concentration of PVA is 0.5wt%; adjust the nitrogen valve to make the pressure in the oil phase reach 0.40MPa, under the action of pressure , the hydrophobic liquid urea-formaldehyde resin is pressed into the water phase through the pores of the glass membrane to obtain oil droplets of uniform size; at the same time, the ammonium chloride in the water phase makes the liquid urea-formaldehyde resin solidify slowly, and the urea-formaldehyde resin can be obtained after separation and drying. Balls; put urea-formaldehyde resin microspheres in a muffl...

example 3

[0026] The model of the external pressure SPG membrane emulsifier is MG-20, and the specification of the SPG membrane is Φ20×L20mm. In the oil tank of SPG emulsifier, add 8g liquid urea-formaldehyde resin as carbon source, the condition that liquid urea-formaldehyde resin used needs to satisfy is the same as example 1. The concentration of Tween-80 in the water phase is 0.4wt%, the concentration of ammonium chloride is 0.1mol / L, and the concentration of PVA is 0.25wt%; adjust the nitrogen valve to make the pressure in the oil phase reach 0.25MPa, under the action of pressure , the hydrophobic liquid urea-formaldehyde resin is pressed into the water phase through the pores of the glass membrane to obtain oil droplets of uniform size; at the same time, the ammonium chloride in the water phase makes the liquid urea-formaldehyde resin solidify slowly, and the urea-formaldehyde resin can be obtained after separation and drying. Balls; put urea-formaldehyde resin microspheres in a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com