Magnetic microsphere resin with high specific surface area and preparation method and application thereof

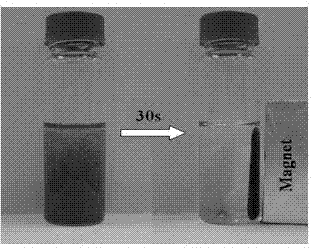

A high specific surface area, magnetic microsphere technology, applied in the direction of microsphere preparation, magnetic materials, magnetic objects, etc., can solve the problems of inability to effectively prepare magnetic polymer materials, obtain magnetic materials, and contaminate membranes, etc., to achieve convenience Separation method, high adsorption capacity, effect of enhancing lipophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Using 20g FeCl 2 4H 2 O and 100g FeCl 3 ·6H 2 O prepared magnetic nanoparticles, modified with 20g oleic acid. The oil phase consists of 50g of high-purity divinylbenzene (99.99%), 10g of n-heptane, 15g of toluene, and 1.6g of benzoyl peroxide. Dissolve 10g of gelatin in 500ml of water to form the water phase. The oil phase and the magnetic nanoparticles are ultrasonically mixed, and the SPG membrane with a pore size of 2 μm is selected to pass through the membrane under a nitrogen pressure of 0.045 MPa to form a uniform emulsion. Transfer the emulsion into a three-necked bottle, stir slowly, raise the temperature to 75°C to initiate the reaction, polymerize for 8 hours, then gradually raise the temperature to 90°C, and react for 10 hours. Centrifuge the obtained microspheres, wash with water, ethanol, and acetone, add dichloroethane to swell after drying, put in ferric chloride with 80% resin mass under nitrogen protection, and react at 80°C for 12 hours, ethanol,...

Embodiment 2

[0035] Using 4.5g FeCl 2 4H2 O and 27g FeCl 3 ·6H 2 O prepared magnetic nanoparticles, modified with 5g oleic acid. The oil phase is composed of 50 g of high-purity divinylbenzene, 100 g of n-hexane, 0.5 g of azobisisobutyronitrile, and 1 g of benzoyl peroxide. Dissolve 10g of gelatin and 10g of polyvinyl alcohol in 500ml of water to form the water phase. The oil phase and the magnetic nanoparticles are ultrasonically mixed, and a SPG membrane with a pore size of 5 μm is selected to form a uniform emulsion under a nitrogen pressure of 0.03 MPa. Transfer the emulsion into a three-necked bottle, stir slowly, raise the temperature to 70°C to initiate the reaction, polymerize for 6 hours, then gradually raise the temperature to 85°C, and react for 14 hours. Centrifuge the obtained microspheres, wash with water, ethanol and acetone, add nitrobenzene to swell after drying, put in zinc chloride with 20% resin mass under the protection of nitrogen, react at 90°C for 16 hours, wash...

Embodiment 3

[0038] Using 23.3g FeCl 2 4H 2 O and 63g FeCl 3 ·6H 2 O prepared magnetic nanoparticles, modified with 15g oleic acid. The oil phase consisted of 50 g of high-purity divinylbenzene, 50 g of isobutanol, and 0.5 g of azobisisobutyronitrile. Dissolve 5g of hydroxyethyl cellulose and 10g of polyvinyl alcohol in 500ml of water to form an aqueous phase. The oil phase and the magnetic nanoparticles are ultrasonically mixed, and a SPG membrane with a pore size of 10 μm is selected to form a uniform emulsion under a nitrogen pressure of 0.01 MPa. Transfer the emulsion into a three-necked bottle, stir slowly, raise the temperature to 65°C to initiate the reaction, polymerize for 10 hours, then gradually raise the temperature to 90°C, and react for 8 hours. Centrifuge the obtained microspheres, wash with water, ethanol, and acetone, add nitrobenzene to swell after drying, put in aluminum chloride with a resin mass of 30% under nitrogen protection, react at 90°C for 16 hours, wash wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com