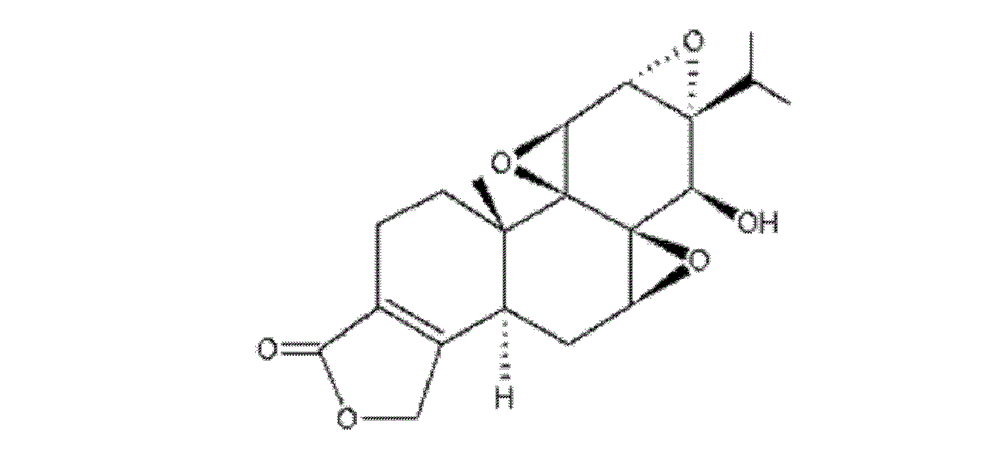

Triptolide solid lipid nanoparticle as well as preparation method and application thereof

A technology of solid lipid nanometer and triptolide, which can be used in pharmaceutical formulations, medical preparations with inactive ingredients, inactive ingredients of oil/fat/wax, etc., and can solve the problems of poor reproducibility, accurate particle size and distribution. control and other issues, to achieve the effects of mild conditions, simple and fast preparation methods, and stable processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation method of triptolide solid lipid nanoparticles described in this embodiment comprises the following steps:

[0041] (1) Preparation of pre-emulsion: Dissolve 600 mg of triptolide, 2.0 g of egg yolk lecithin, 3.2 g of glyceryl palmitate, and 0.8 g of glyceryl monolinoleate in 30 mL of dichloromethane as the oil phase, lipids and lipids The mass ratio of the carrier is 1:2, the mass ratio of triptolide and the mixed lipid is 1:10, and the ratio of the mixed lipid to the organic solvent is 1g:5mL;

[0042] Then disperse the oil phase in 60mL water phase, containing 6.0g polyoxyethylene hydrogenated castor oil in the water phase, heating to 60°C, 30,000r / min, high shear for 1min to obtain the oil-in-water type pre-emulsion; oil phase and water The phase volume ratio is 1:2, and the mass ratio of emulsifier to deionized water is 1:10;

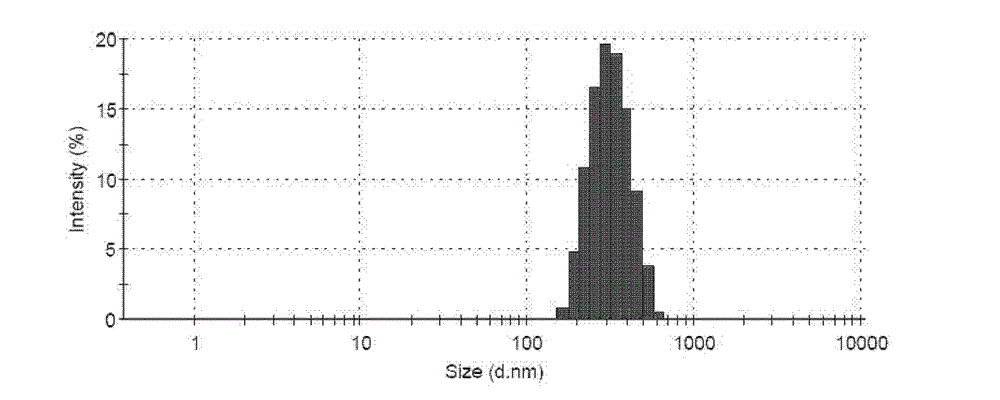

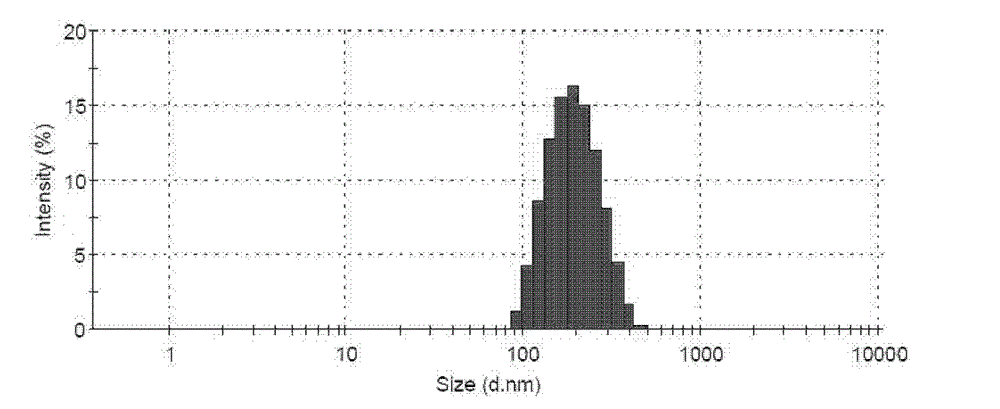

[0043] (2) Emulsion preparation: Using rapid membrane emulsification equipment, the oil-in-water pre-emulsion was circulate...

Embodiment 2

[0048] The preparation method of triptolide solid lipid nanoparticles described in this embodiment comprises the following steps:

[0049] (1) Preparation of pre-emulsion: Dissolve 600 mg of triptolide, 2.0 g of egg yolk lecithin, 3.2 g of glyceryl palmitate, and 0.8 g of glyceryl monolinoleate in 30 mL of ethyl acetate as the oil phase, lipids and lipids The mass ratio of the carrier is 1:2, the mass ratio of triptolide and the mixed lipid is 1:10, and the ratio of the mixed lipid to the organic solvent is 1g:5mL;

[0050] Then disperse the oil phase in 60mL water phase, containing 6.0g of polyoxyethylene hydrogenated castor oil in the water phase, heating to 60°C, 30,000r / min, high shear for 5min to obtain the oil-in-water type pre-emulsion; oil phase and water The phase volume ratio is 1:2, and the mass ratio of emulsifier to deionized water is 1:10;

[0051] (2) Emulsion preparation: Using rapid membrane emulsification equipment, the oil-in-water pre-emulsion is circulate...

Embodiment 3

[0056] The preparation method of triptolide solid lipid nanoparticles described in this embodiment comprises the following steps:

[0057] (1) Preparation of pre-emulsion: Dissolve 600 mg of triptolide, 2.0 g of egg yolk lecithin, 3.2 g of glyceryl palmitate, and 0.8 g of glyceryl monolinoleate in 30 mL of dichloromethane as the oil phase, lipids and lipids The mass ratio of the carrier is 1:2, the mass ratio of triptolide and the mixed lipid is 1:10, and the ratio of the mixed lipid to the organic solvent is 1g:5mL;

[0058] Then disperse the oil phase in 60mL water phase, containing 6.0g of polyoxyethylene hydrogenated castor oil in the water phase, heating to 60°C, 10,000r / min, high shear for 5min to obtain the oil-in-water type pre-emulsion; oil phase and water The phase volume ratio is 1:2, and the mass ratio of emulsifier to deionized water is 1:10;

[0059] (2) Emulsion preparation: using fast membrane emulsification equipment, the oil-in-water pre-emulsion is circulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com