Micro-capsule ultrasonic contrast agent and preparation method thereof

A technology of ultrasound contrast agent and microcapsule, which is applied in the direction of echo/ultrasound imaging agent, microcapsule, capsule delivery, etc. It can solve the problem that the size of the microcapsule is not concentrated, it is difficult to control and adjust the particle size and particle size of the microcapsule Distribution and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

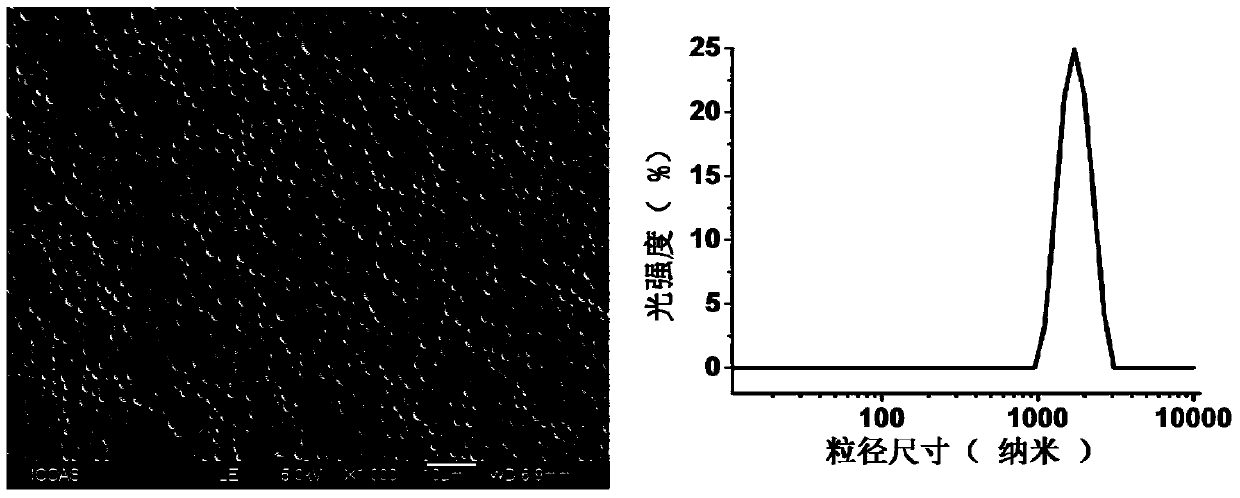

[0042] Embodiment 1, preparation of microcapsule type ultrasound contrast agent

[0043] PLA with a number average molecular weight of 5,000 was dissolved in dichloromethane to prepare a 1 mg / mL solution. After the solution was mixed with water at a volume ratio of 40:1, it was ultrasonicated for 240 seconds at a power of 500 watts to obtain a water-in-oil primary emulsion. At a stirring speed of 2000 rpm, the primary emulsion obtained above was dropped into 50 times the volume of the primary emulsion in an aqueous solution of polyvinyl alcohol (5%, mass concentration), and stirred for 1 minute. The resulting mixed system was poured into a storage tank of a rapid membrane emulsification device (with a membrane pore size of 7 microns), and passed through the membrane 10 times under a nitrogen pressure of 180 kPa. The obtained water-in-oil-in-water multiple emulsion was stirred at room temperature for 24 hours at a speed of 60 rpm / membrane minute. The product was collected by ...

Embodiment 2

[0046] Embodiment 2, preparation of microcapsule type ultrasound contrast agent

[0047] PLGA having a number average molecular weight of 20,000 was dissolved in dichloromethane to prepare a 2 mg / mL solution. After the solution was mixed with water at a volume ratio of 35:1, it was ultrasonicated for 70 seconds at a power of 350 watts to obtain a water-in-oil primary emulsion. At a stirring speed of 1000 rpm, the primary emulsion was dropped into an aqueous solution of polyvinyl alcohol (5%, mass concentration) 40 times the volume of the primary emulsion, and stirred for 25 minutes. The resulting mixed system was poured into a storage tank of a rapid membrane emulsification device (with a membrane pore size of 7 microns), and passed through the membrane once under a nitrogen pressure of 50 kPa. The obtained water-in-oil-in-water multiple emulsion was stirred at room temperature at a speed of 150 rpm for 9 hours. The product was collected by centrifugation. The resulting pro...

Embodiment 3

[0050] Embodiment 3, preparation of microcapsule type ultrasound contrast agent

[0051] PLC with a number average molecular weight of 50,000 was dissolved in chloroform to prepare a 4 mg / mL solution. After the solution was mixed with water at a volume ratio of 30:1, it was ultrasonicated for 90 seconds at a power of 450 watts to obtain a water-in-oil primary emulsion. At a stirring speed of 120 rpm, the primary emulsion was dropped into an aqueous solution of polyvinyl alcohol (4.5%, mass concentration) 35 times the volume of the primary emulsion, and stirred for 30 minutes. The resulting mixed system was poured into a storage tank of a rapid membrane emulsification device (with a membrane pore size of 8 microns), and passed through the membrane 7 times under a nitrogen pressure of 140 kPa. The obtained water-in-oil-in-water multiple emulsion was stirred at room temperature at a speed of 80 rpm for 18 hours. The product was collected by centrifugation. The resulting produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass volume concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com