Manufacturing method of a membrane and a membrane thereof, for emulsification

A manufacturing method and membrane emulsification technology, applied in the field of membrane emulsification, can solve problems such as difficult preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

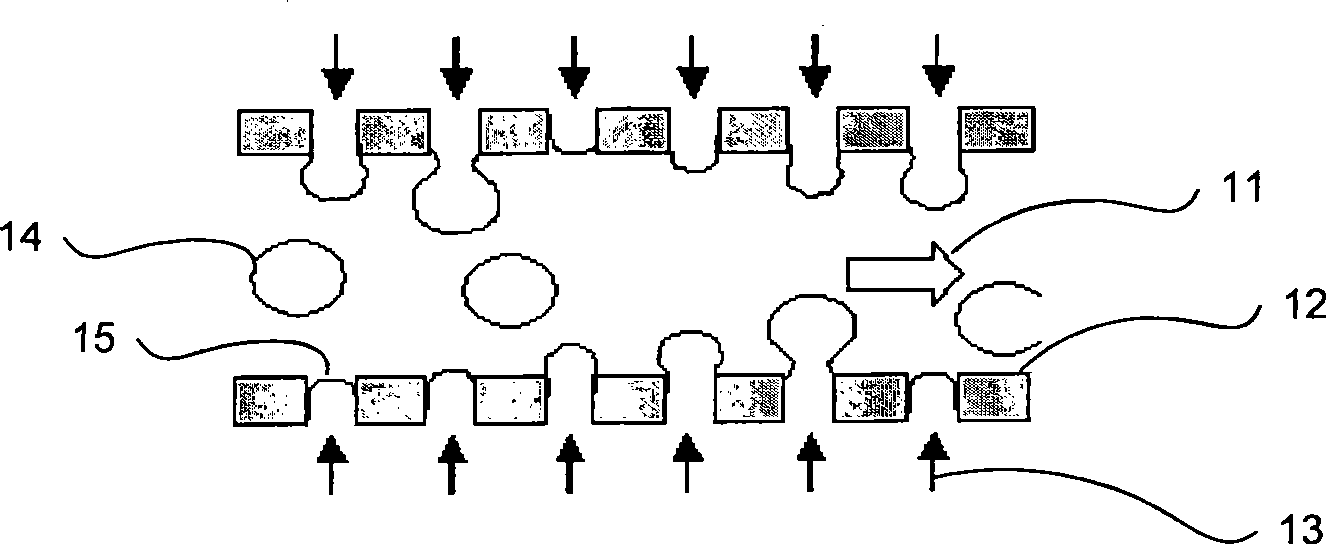

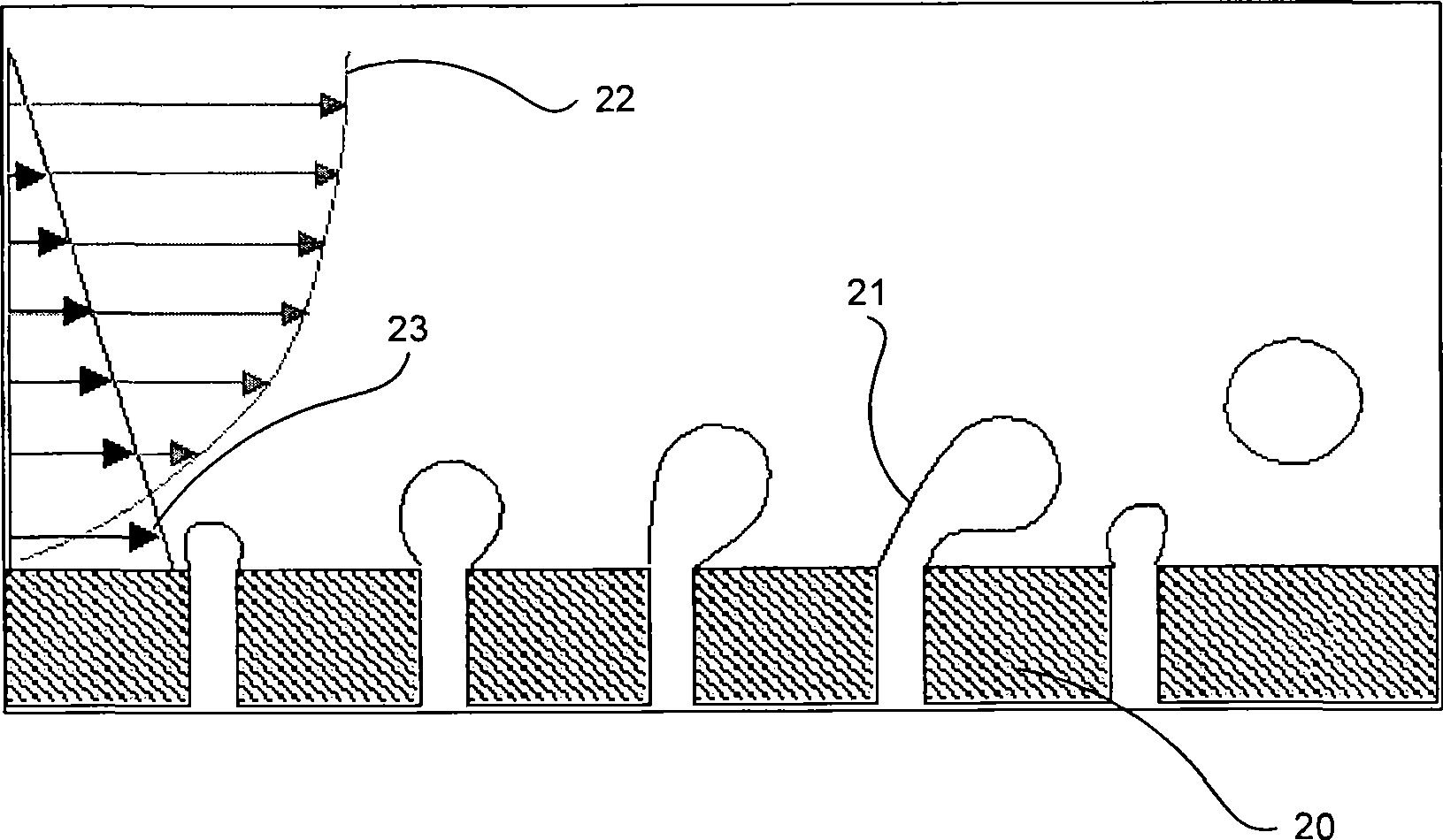

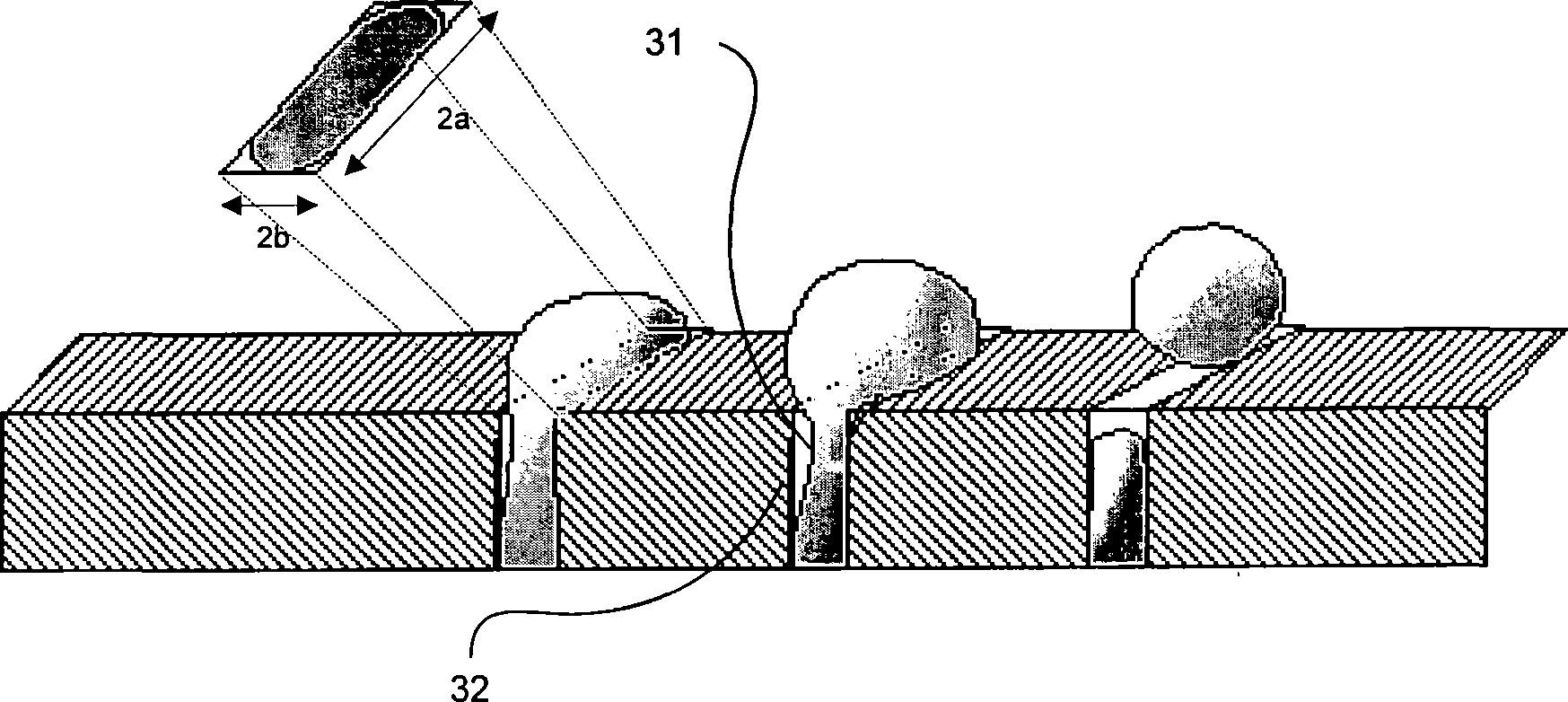

[0032] By using membranes obtained from the preparation method according to the invention, the prior art pressure drop problem along the module is eliminated and droplet formation does not require cross-flow, which in turn allows a wider range of design options. New products applied to various fields can be commercially viable by solving the problems of existing technical solutions regarding cost, scale-up and durability.

[0033] Due to the development of highly monodisperse membrane emulsification technology, the preparation of microcapsules and microspheres is an emerging technology that has been decisively impacted. An example of an application stemming from the use of membrane technology where particles require sizes and monodisperse that are difficult to achieve by other conventional techniques is (i) encapsulation of anticancer drugs in drug delivery systems that, after injection into the blood, slow release into target organs, (ii) preparation of porous beads used as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com