Chitosan microsphere and preparation method thereof

A technology of chitosan microspheres and chitosan, which is applied in the preparation of microspheres and microcapsule preparations, can solve the problems of difficulty in regulating the particle size and distribution of microspheres, harsh conditions, and uneven particle sizes, and achieve The effect of mild conditions, simple process and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of chitosan microsphere, comprises the following steps:

[0030] a) dissolving the modified chitosan in an organic solvent, then adding a crosslinking agent to obtain a modified chitosan oil solution; then adding the modified chitosan oil solution to an emulsifier aqueous solution for pre-emulsification, Obtain an oil-in-water pre-emulsion;

[0031] b) The oil-in-water pre-emulsion obtained in step a) is subjected to rapid membrane emulsification, and the obtained emulsion is centrifuged to collect the precipitate after stirring; finally, the obtained precipitate is successively washed with water and freeze-dried to obtain chitosan microspheres; The membrane used in the rapid membrane emulsification is an SPG membrane with a pore size of 1 μm to 9 μm.

[0032] In the invention, firstly, the modified chitosan is dissolved in an organic solvent, and then a crosslinking agent is added to obtain the modified chitosan oil ...

Embodiment 1

[0063] Preparation of modified chitosan microspheres:

[0064] (1) carboxymethyl chitosan is dissolved in methylene chloride, is made into the solution of 50mg / ml, wherein adds the sodium trimetaphosphate of carboxymethyl chitosan quality 25%; Under the stirring speed of 1800r / min , adding the above-mentioned solution to 50 times the volume of a 2% polyvinyl alcohol aqueous solution and stirring for 1 minute to obtain a pre-emulsion.

[0065] (2) Pour the pre-emulsion obtained in step (1) into a rapid membrane emulsification device, and pass through the membrane 5 times under 0.2MPa inert gas pressure; the obtained emulsion is stirred at room temperature for 10h at a speed of 360r / min; the product is collected by centrifugation, After the product was washed several times with water, it was freeze-dried to obtain microspheres with an average particle diameter of 500 nm.

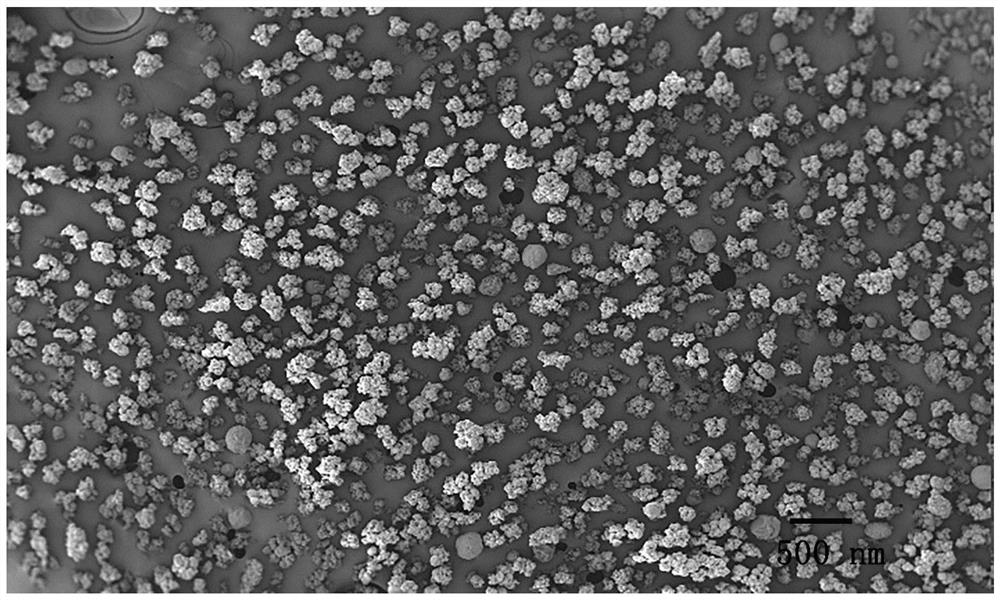

[0066] The scanning electron micrograph of the chitosan microsphere that the preparation method that the e...

Embodiment 2

[0068] Preparation of modified chitosan microspheres:

[0069] (1) hydroxypropyl chitosan is dissolved in ethyl acetate, is made into the solution of 100mg / ml, wherein adds the sodium trimetaphosphate of carboxymethyl chitosan quality 25%; Under the stirring speed of 800r / min , adding the above solution to 10 times the volume of 5% polyvinyl alcohol aqueous solution and stirring for 1 minute to obtain a pre-emulsion.

[0070] (2) Pour the pre-emulsion obtained in step (1) into a fast membrane emulsification device, and pass through the membrane 5 times under 0.2MPa inert gas pressure; the obtained emulsion is stirred at room temperature for 10h at a speed of 400r / min; the product is collected by centrifugation, After the product was washed several times with water, it was freeze-dried to obtain microspheres with an average particle size of 1 μm.

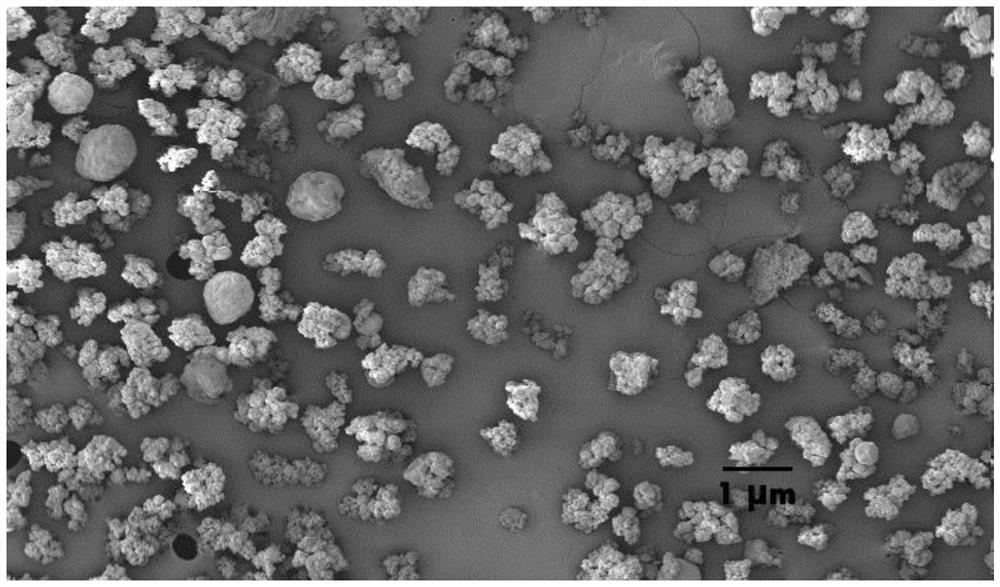

[0071] The scanning electron micrograph of the chitosan microsphere that the preparation method that the embodiment of the present...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com