Dyestuff with polymerizable group and preparation of microspheres containing dyestuff

A technology of polymeric bases and dyes, which is applied in the direction of organic dyes, hydroxyanthraquinone dyes, methine/polymethine dyes, etc. It can solve the problems of poor compatibility between resins and pigments, easy to fall off pigments, etc., and achieve regular shape of microspheres , Good size and shape uniformity, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

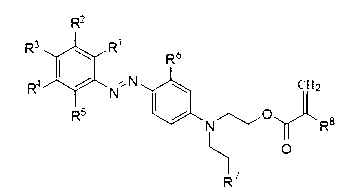

[0053] 1) Preparation of diazonium salt: Mix organic acid, water, and substituted aniline in a reactor, add sodium nitrite solution dropwise at -5°C, and keep the temperature not higher than 0°C during the dropping process. After the dropwise addition, react at 0-5°C for 0.5-3 hours to obtain the diazonium salt.

[0054]2) Coupling reaction: Add the prepared diazonium salt solution into hydroxyethylaniline with substituents, and control the reaction temperature during the dropping process to not be higher than 20°C. After the dropping is completed, react for 1 to 10 hours. A dye bearing a hydroxyethyl group is obtained.

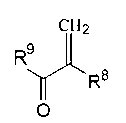

[0055] 3) Put the dye with hydroxyethyl group, triethylamine, and acetonitrile in the reactor and mix them evenly, add the double-bonded acid chloride dropwise at 50°C~60°C, after the dropwise addition, reflux for 3~12 hours to obtain Polymerizable dyes with double bond functional groups;

[0056] ②The steps are:

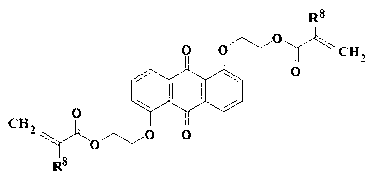

[0057] 1) Affinity substitution reaction:...

preparation Embodiment 1

[0060] Add 20-60 parts of water, 3-5 parts of 37% concentrated hydrochloric acid, and 1 part of aniline into the reaction bottle, stir and dissolve at room temperature, and when the temperature in the reaction bottle is lowered to -5°C, add sodium nitrite solution dropwise, During the addition process, keep the temperature not higher than 0°C. After the dropwise addition, keep the temperature in the kettle at 0-5°C and react for 0.5-3 hours to obtain the diazonium salt. Add 5 to 10 parts of water and 0.85 to 1 part of N-ethyl-N-hydroxyethyl m-methylaniline to the reaction bottle. After fully stirring, add the prepared diazonium salt dropwise with a constant pressure burette. The dropwise addition process Control the reaction temperature not to be higher than 20°C. After the dropwise addition, react for 1 to 10 hours and then filter. After the filter cake is purified, mix it with 1.2 to 2.5 parts of triethylamine and 5 to 25 parts of acetonitrile in the reactor. Add 2.5~5 part...

preparation Embodiment 2

[0062] Add 20-60 parts of water, 3-5 parts of 37% concentrated hydrochloric acid, and 1 part of aniline into the reaction bottle, stir and dissolve at room temperature, and when the temperature in the reaction bottle is lowered to -5°C, add sodium nitrite solution dropwise, During the addition process, keep the temperature not higher than 0°C. After the dropwise addition, keep the temperature in the kettle at 0-5°C and react for 2-3 hours to obtain the diazonium salt. Add 5~10 parts of water and 0.9~1 part of N-ethyl-N-hydroxyethylaniline to the reaction bottle. After fully stirring, add the prepared diazonium salt dropwise with a constant pressure burette, and control the reaction temperature during the dropping process. Not higher than 20°C. After the dropwise addition, react for 5-20 hours and then filter. After the filter cake is purified, mix with 2-3 parts of triethylamine and 30-50 parts of acetonitrile in the reactor, and add dropwise at 60°C. 2.5~5 parts of methacryl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com