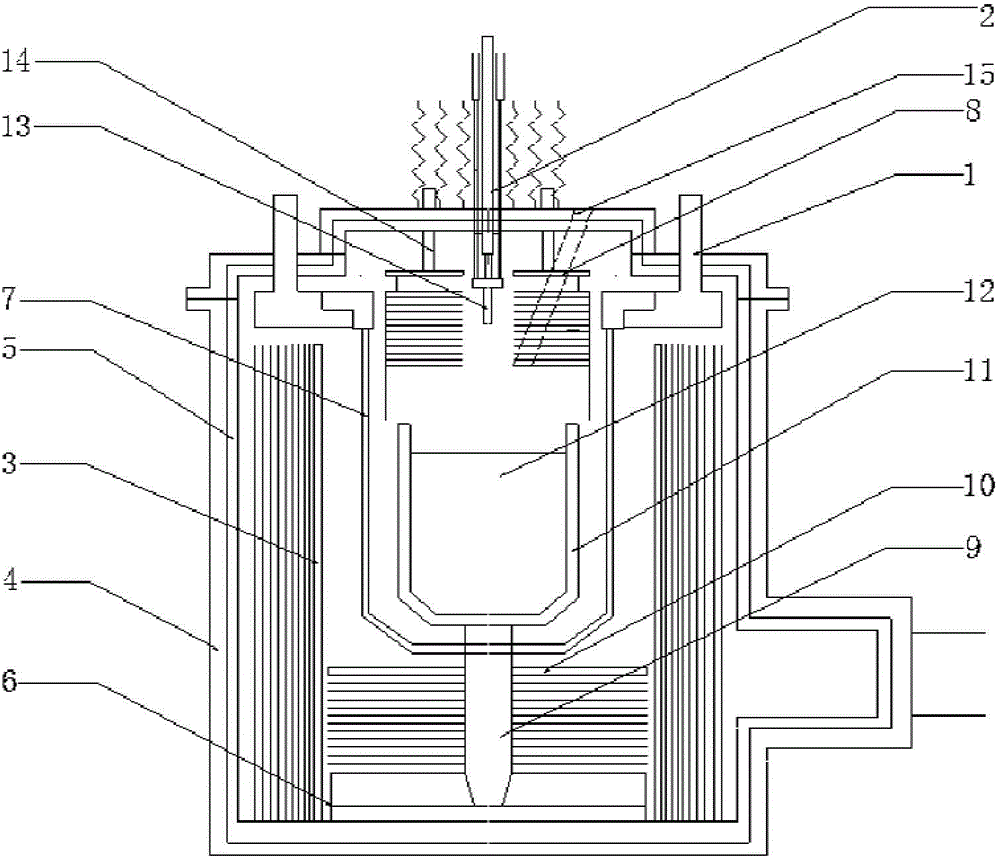

Device for growing crystals by the Tira Kyophyll method

A technology for growing crystals and a foaming method, which is applied in the field of crystal growth devices and devices for growing crystals by pulling and foaming methods, can solve the problems of incompatibility between the pulling method equipment and the foaming method equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

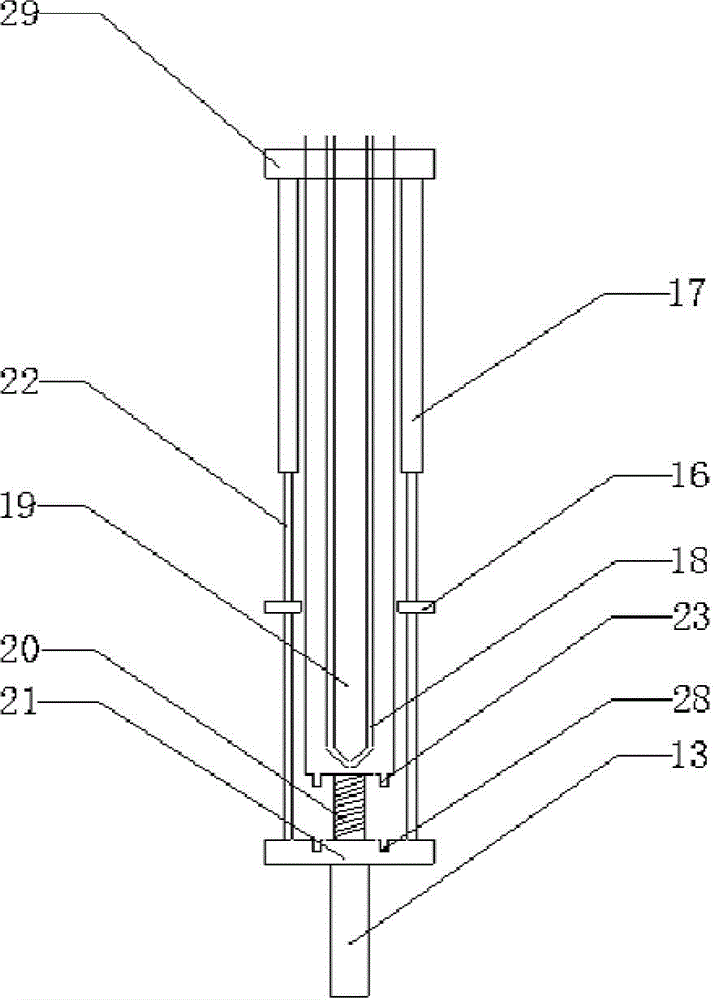

[0045] The following steps are used for the growth of sapphire crystals by the pulling Kyroplasty method:

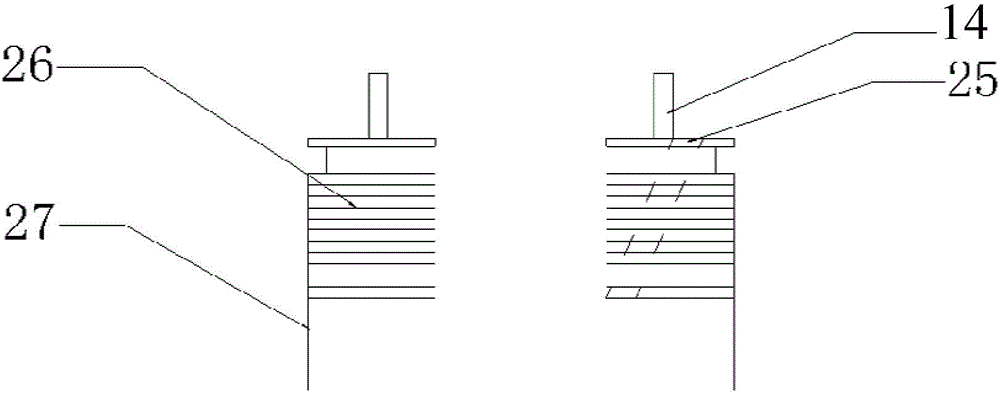

[0046] 1) Put the high-purity alumina raw material (purity ≥ 99.995%) into the crucible 11, adjust the height of the upper insulation cover 8, so that the bottom of the cylindrical tungsten heating sleeve or molybdenum heating sleeve 27 is lower than the upper end of the crucible 11 by 2~ 5cm, vacuum until the pressure in the furnace is less than 10 -3 Pa, and then fill the protective gas until the air pressure in the furnace reaches an absolute pressure of 2-5KPa; adjust the height of the molybdenum rod 22 in the composite seed crystal rod 2, and keep the distance between the seed crystal fixture 21 and the main water-cooled rod 19 at 5-15cm ;

[0047] 2) Increase the power at a certain rate (1000-8000W / h) to increase the temperature in the furnace. After the raw materials are completely melted, adjust the power until a star-shaped stable liquid flow line is formed at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com