New process for preparing porous high polymer reinforced perfluorinated sulfonic acid resin composite membrane

A technology of perfluorosulfonic acid resin and composite membrane, which is applied in sustainable manufacturing/processing, final product manufacturing, fuel cell parts, etc., and can solve problems such as complex equipment requirements and operations, poor dimensional stability, and penetration of working media , to achieve the effects of reduced gas permeability, enhanced proton conductivity, and low pore residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

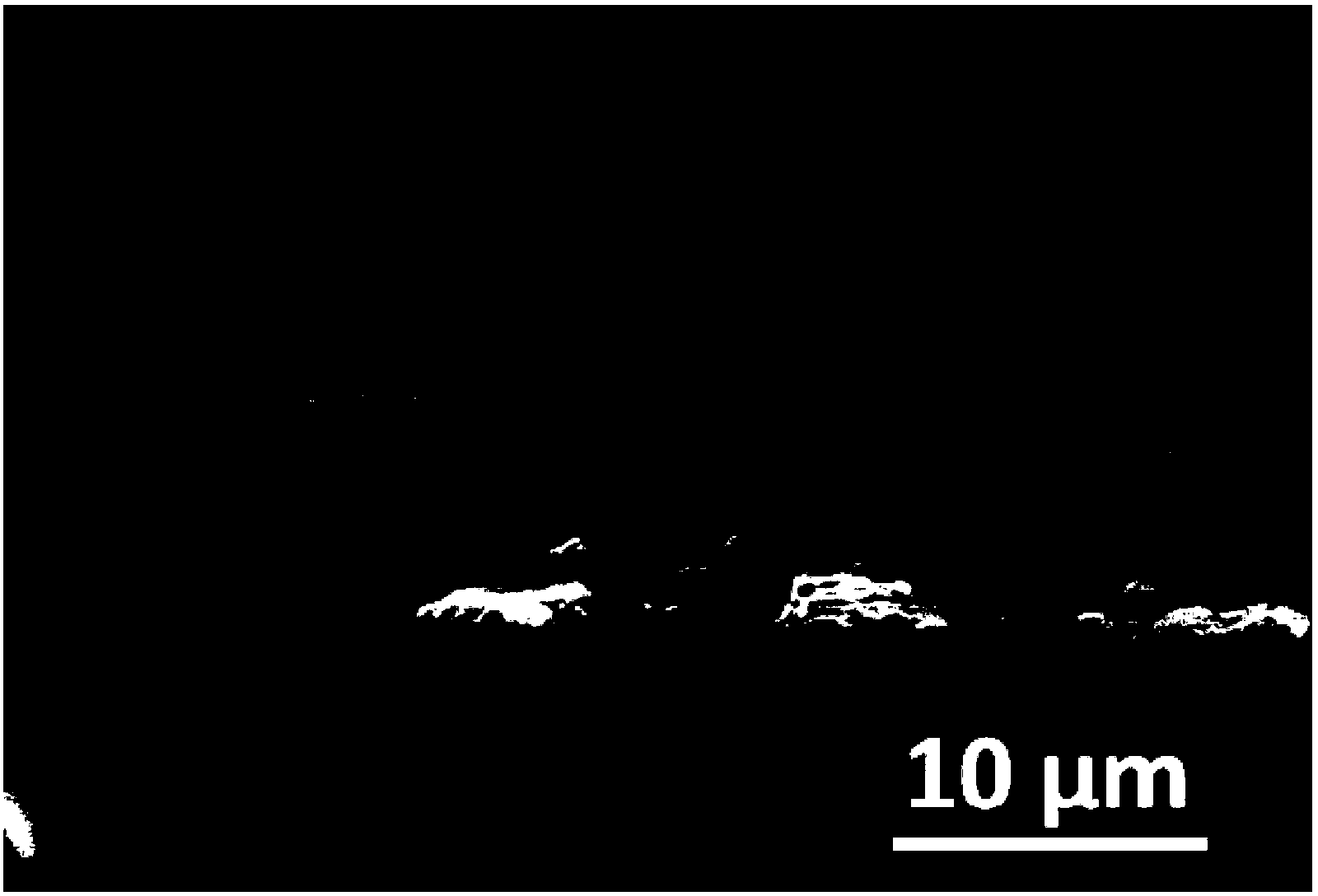

Image

Examples

Embodiment 1

[0065] Dissolve 20g of PFSA precursor resin with IEC=1.12 mol / kg in 180g of perfluoro(methyl decahydronaphthalene), centrifuge the solution and take the supernatant, then pass through the activated aluminum oxide chromatography column, and finally A pure solution was obtained after filtration. The ePTFE membrane is fixed with a stainless steel frame, cleaned with ethanol and dried. Then, the clean ePTFE is immersed in the PFSA precursor resin solution, removed after 5 minutes, and dried in an oven at 120 degrees for 5 minutes. In order to increase the resin loading capacity, impregnation The drying process is generally repeated three times, and finally the film is heat-treated at 160 degrees for 2 hours. The prepared composite membrane was put into 8M NaOH solution and reacted at 80°C for 48 hours for transformation treatment. After transformation, the membrane was washed with deionized water, then immersed in 3M nitric acid for 3 hours, and the nitric acid solution was change...

Embodiment 2

[0067] In this embodiment, the PFSA precursor resin of 10g IEC=1.12 mol / kg is dissolved in 190g hexafluoropropylene trimer, after the solution is centrifuged, the supernatant is taken, and then passed through the activated aluminum oxide chromatographic column, Finally, a pure solution was obtained after filtration. The ePTFE membrane is cleaned with ethanol and dried, spread flat on a clean glass plate, and then sprayed with PFSA precursor resin solution on the surface, and dried in an oven at 120 degrees for 5 minutes. In order to increase the resin load, the spraying and drying process is generally Repeat three times, and finally heat-treat the film at 160 degrees for 2 hours. The prepared composite membrane was put into 8M NaOH solution and reacted at 80°C for 48 hours for transformation treatment. After transformation, the membrane was washed with deionized water, then immersed in 3M nitric acid for 3 hours, and the nitric acid solution was changed every hour. After that...

Embodiment 3

[0069] In this embodiment, the PFSA precursor resin of 5g IEC=1.12 mol / kg is dissolved in 195g hexafluoropropylene trimer, after the solution is centrifuged, the supernatant is taken, and then passed through the activated aluminum oxide chromatographic column, Finally, a pure solution was obtained after filtration. The ePTFE membrane is fixed with a stainless steel frame, cleaned with ethanol and dried. Then, the clean ePTFE is immersed in the PFSA precursor resin solution, removed after 5 minutes, and dried in an oven at 120 degrees for 5 minutes. In order to increase the resin loading capacity, impregnation The drying process is generally repeated three times, and finally the film is heat-treated at 160 degrees for 2 hours. The prepared composite membrane was put into 8M NaOH solution and reacted at 80°C for 48 hours for transformation treatment. After transformation, the membrane was washed with deionized water, then immersed in 3M nitric acid for 3 hours, and the nitric ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com