Dyestuff with polymerizable group and preparation of microspheres containing dyestuff

A polymer-based, microsphere technology, applied in the direction of organic dyes, hydroxyanthraquinone dyes, methionyl/polymethine-based dyes, etc., can solve the problems of poor compatibility between resin and pigment, easy shedding of pigments, etc., and achieve the shape of microsphere particles. Regularity, good size and shape uniformity, and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

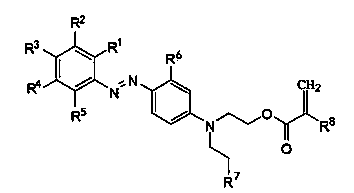

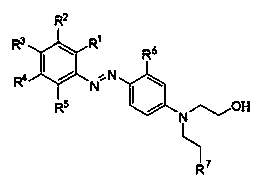

[0053] 1) Preparation of diazonium salt: Mix organic acid, water, and substituted aniline in a reactor, add sodium nitrite solution dropwise at -5°C, and keep the temperature not higher than 0°C during the dropping process. After the dropwise addition, react at 0-5°C for 0.5-3 hours to obtain the diazonium salt.

[0054]2) Coupling reaction: Add the prepared diazonium salt solution into hydroxyethylaniline with substituents, and control the reaction temperature during the dropping process to not be higher than 20°C. After the dropping is completed, react for 1 to 10 hours. A dye bearing a hydroxyethyl group is obtained.

[0055] 3) Put the dye with hydroxyethyl group, triethylamine, and acetonitrile in the reactor and mix them evenly, add the double-bonded acid chloride dropwise at 50°C~60°C, after the dropwise addition, reflux for 3~12 hours to obtain Polymerizable dyes with double bond functional groups;

[0056] ②The steps are:

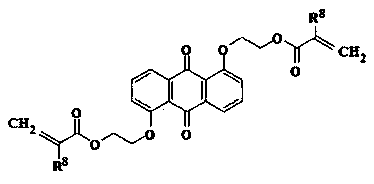

[0057] 1) Affinity substitution reaction:...

preparation Embodiment 1

[0060] Add 20-60 parts of water, 3-5 parts of 37% concentrated hydrochloric acid, and 1 part of aniline into the reaction bottle, stir and dissolve at room temperature, and when the temperature in the reaction bottle is lowered to -5°C, add sodium nitrite solution dropwise, During the addition process, keep the temperature not higher than 0°C. After the dropwise addition, keep the temperature in the kettle at 0-5°C and react for 0.5-3 hours to obtain the diazonium salt. Add 5 to 10 parts of water and 0.85 to 1 part of N-ethyl-N-hydroxyethyl m-methylaniline to the reaction bottle. After fully stirring, add the prepared diazonium salt dropwise with a constant pressure burette. The dropwise addition process Control the reaction temperature not to be higher than 20°C. After the dropwise addition, react for 1 to 10 hours and then filter. After the filter cake is purified, mix it with 1.2 to 2.5 parts of triethylamine and 5 to 25 parts of acetonitrile in the reactor. Add 2.5~5 part...

preparation Embodiment 2

[0062] Add 20-60 parts of water, 3-5 parts of 37% concentrated hydrochloric acid, and 1 part of aniline into the reaction bottle, stir and dissolve at room temperature, and when the temperature in the reaction bottle is lowered to -5°C, add sodium nitrite solution dropwise, During the addition process, keep the temperature not higher than 0°C. After the dropwise addition, keep the temperature in the kettle at 0-5°C and react for 2-3 hours to obtain the diazonium salt. Add 5~10 parts of water and 0.9~1 part of N-ethyl-N-hydroxyethylaniline to the reaction bottle. After fully stirring, add the prepared diazonium salt dropwise with a constant pressure burette, and control the reaction temperature during the dropping process. Not higher than 20°C. After the dropwise addition, react for 5-20 hours and then filter. After the filter cake is purified, mix with 2-3 parts of triethylamine and 30-50 parts of acetonitrile in the reactor, and add dropwise at 60°C. 2.5~5 parts of methacryl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com