Dual-hole polysaccharide microspheres, preparation method and purpose thereof

A polysaccharide and microsphere technology, applied in pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problems of broken balls, deformation of microspheres, and unnecessary use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

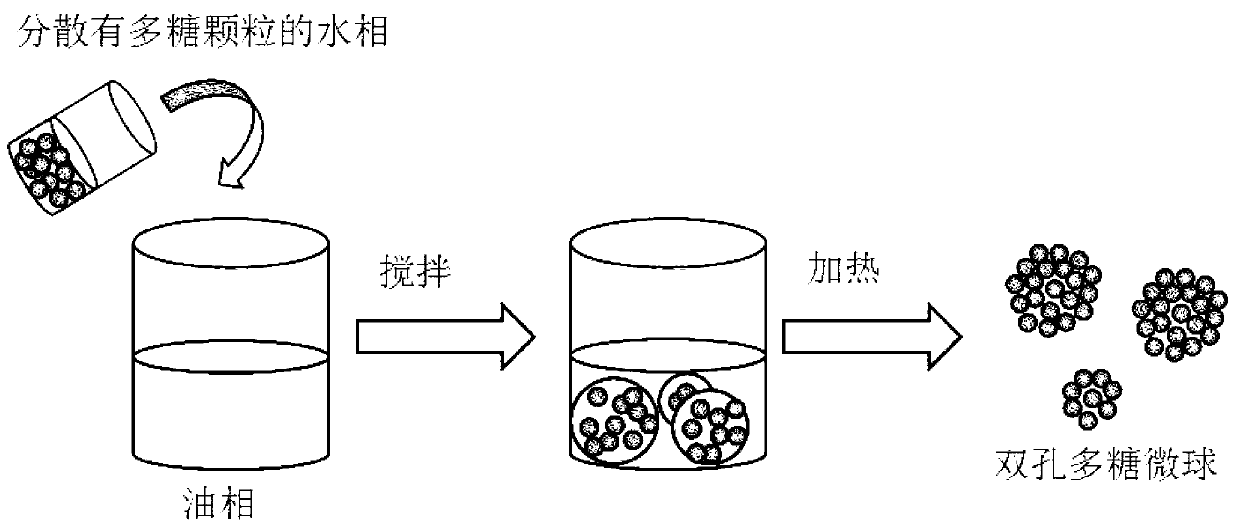

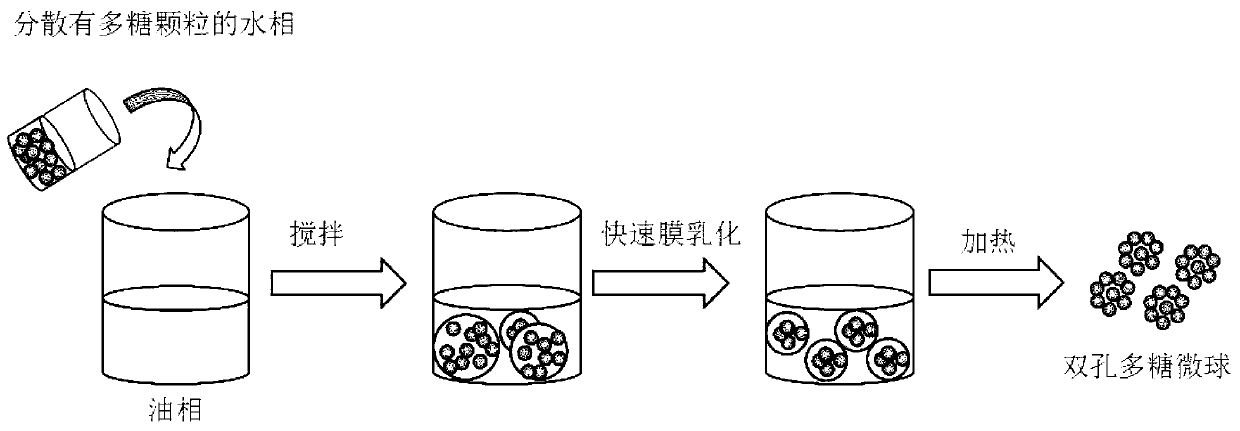

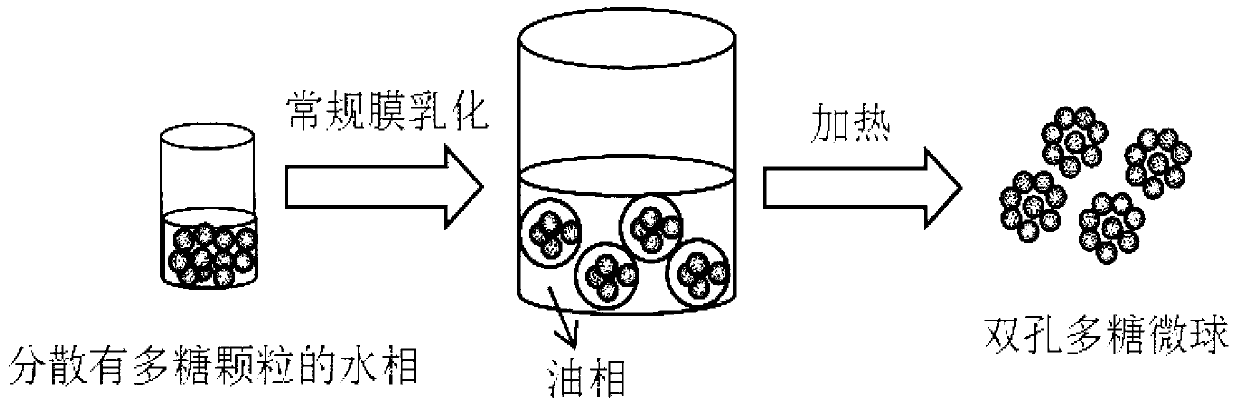

Method used

Image

Examples

Embodiment 1

[0100] Accurately weigh a certain amount of wet agarose particles (the molecular weight of agarose is 120,000 Daltons, the mass concentration of agarose in the agarose particles is 10wt%, the particle size of the agarose particles is 2 μm, the particle size of the agarose particles The distribution coefficient is 15%, and the particle size distribution diagram is as follows Figure 5 shown), and then disperse the agarose particles into the water phase under magnetic stirring (the water phase is 20wt% ethanol aqueous solution, the volume of the water phase is 1mL, the water phase contains polyvinyl alcohol with a concentration of 0.1wt%, and the water phase The mass concentration of agarose particles is 20wt%), and the magnetic stirring speed is 500rpm. Add the water phase containing agarose particles into the oil phase under mechanical stirring (the oil phase is a mixed solvent of liquid paraffin and petroleum ether, the volume ratio of liquid paraffin to petroleum ether is 11...

Embodiment 2

[0102] Macroporous agarose microspheres were prepared by the same method as in Example 1, but the difference was in the properties of the agarose particles. Accurately weigh a certain amount of wet agarose particles (the molecular weight of agarose is 80,000 Daltons, the mass concentration of agarose in the agarose particles is 4wt%, the particle diameter of the agarose particles is 50nm, the particle diameter of the agarose particles The distribution coefficient is 10%), and then disperse the agarose particles into the water phase under magnetic stirring (the water phase is 50wt% ethanol aqueous solution, the volume of the water phase is 1mL, and the mass concentration of the agarose particles in the water phase is 50wt%) , the magnetic stirring speed is 1000rpm. Add the water phase containing agarose particles into the oil phase under mechanical stirring (the oil phase is a mixed solvent of liquid paraffin and petroleum ether, the volume ratio of liquid paraffin and petroleu...

Embodiment 3

[0105]Double-hole chitosan microspheres were prepared by the same method as in Example 1, except that chitosan particles were used instead. Accurately take a certain amount of wet chitosan particles (the chitosan molecular weight is 780,000 daltons, the mass concentration of chitosan in the chitosan particles is 1.5wt%, and the particle diameter of the chitosan particles is 4 μm, The particle size distribution coefficient of chitosan particles is 12%), and then the chitosan particles are dispersed into the water phase under the effect of homogeneity (the water phase is 40wt% acetone aqueous solution, the volume of the water phase is 1mL, and the shell in the water phase The mass concentration of polysaccharide particles is 70wt%), the homogenization speed is 6000rpm, and the homogenization time is 1min. The aqueous phase containing chitosan particles is added to the oil phase under magnetic stirring (the oil phase is cyclohexane, the volume of the oil phase is 50mL, and the oi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com