Microbeads and preparing method and application thereof

A microbead and polymer technology, applied in the chemical industry, can solve problems such as discomfort, skin irritation, and limit the wide application of polylactic acid microbeads, and achieve the effects of skin comfort, low irritation, and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention provides a method for preparing microbeads described in the above technical solution, comprising:

[0048] The raw material including biodegradable polymer is prepared into spherical microbeads by adopting emulsion solvent evaporation method, membrane emulsification method, spray drying method or polymerization method.

[0049] In the present invention, the type and source of the biodegradable polymer are consistent with the type and source of the biodegradable polymer described in the above technical solution, and will not be repeated here.

[0050] In the present invention, the method for preparing the biodegradable polymer into spherical microbeads may be an emulsion solvent evaporation method, a membrane emulsification method, a spray drying method or a polymerization method. In an embodiment of the present invention, the process of the emulsion solvent volatilization method is to volatilize the solvent in the emulsion of the biodegradable poly...

Embodiment 1

[0071] 1.25 mL of 5% NH 4 HCO 3 The solution was added to 4 mL of chloroform solution of polylactic acid with a mass concentration of 6.25% for emulsification to obtain a primary emulsion;

[0072] The primary emulsion was poured into 150 mL of an aqueous solution of polyvinyl alcohol with a mass concentration of 0.1%, and stirred at room temperature at a speed of 400 rpm for 4 hours to obtain polylactic acid spherical microbeads with a porous structure.

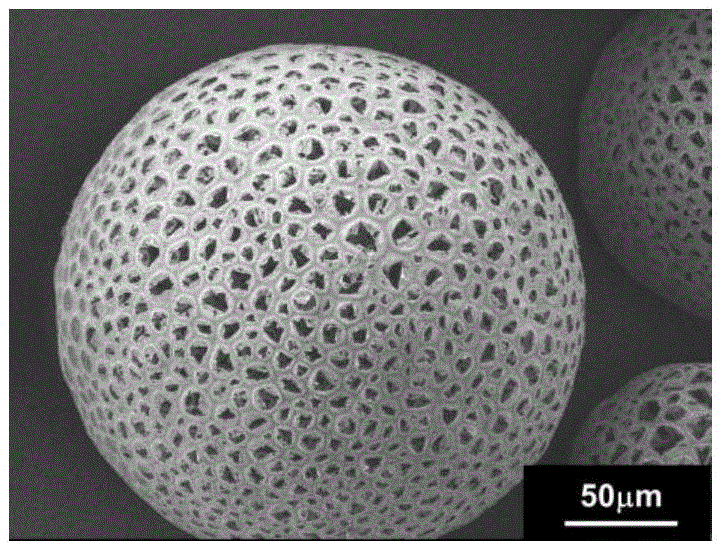

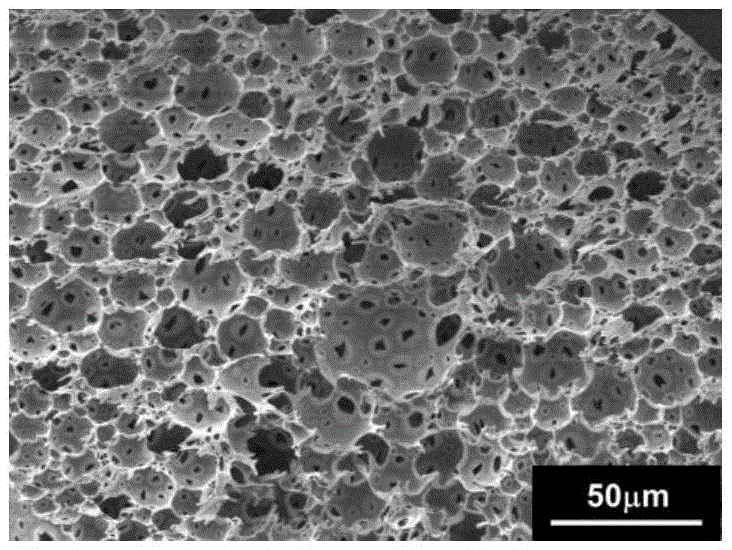

[0073] The polylactic acid spherical microbeads prepared in Example 1 of the present invention and their cross-sections were tested by scanning electron microscopy, and the test results were as follows: figure 1 and figure 2 as shown, figure 1 Scanning electron microscope picture of polylactic acid spherical microbeads prepared in Example 1 of the present invention, figure 2 The scanning electron microscope picture of the polylactic acid spherical microbead section that is prepared in Example 1 of the present invention...

Embodiment 2

[0077] 1.25 mL of 10% NH 4 HCO 3 The solution is added into 4 mL of chloroform solution of polylactic acid and cellulose copolymer with a mass concentration of 6.25% for emulsification to obtain a primary emulsion; the preparation method of the copolymer of polylactic acid and cellulose is: using stannous octoate as a catalyst , by grafting polylactic acid on cellulose by ring-opening polymerization of lactide to prepare a copolymer of polylactic acid and cellulose.

[0078] The primary emulsion was poured into 150 mL of polyvinyl alcohol aqueous solution with a mass concentration of 0.1%, and stirred at room temperature at a speed of 400 rpm for 4 hours to obtain copolymer spherical microbeads of polylactic acid and cellulose with a hollow structure.

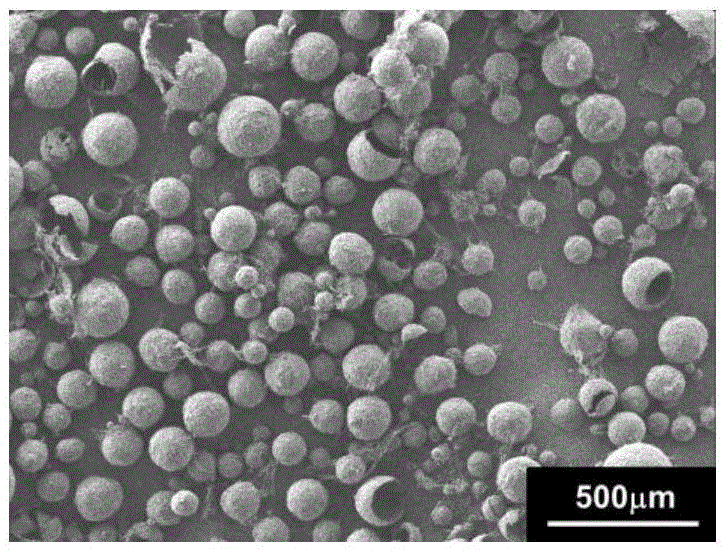

[0079] The copolymer spherical microbead of polylactic acid and cellulose prepared in Example 2 of the present invention and its section were subjected to scanning electron microscopy tests, and the test results were as follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com