Pickering emulsion with uniform particle size, and preparation method and application thereof

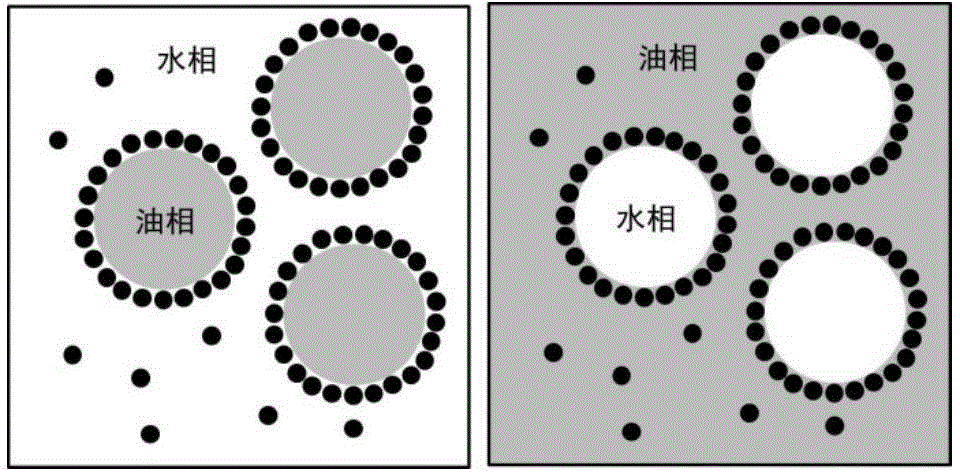

An emulsion and uniform technology, applied in the field of materials, can solve the problems of wide particle size distribution, unstable emulsion, uncontrollable emulsion particle size, etc., to achieve uniform particle size, avoid aging phenomenon, and facilitate long-term storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

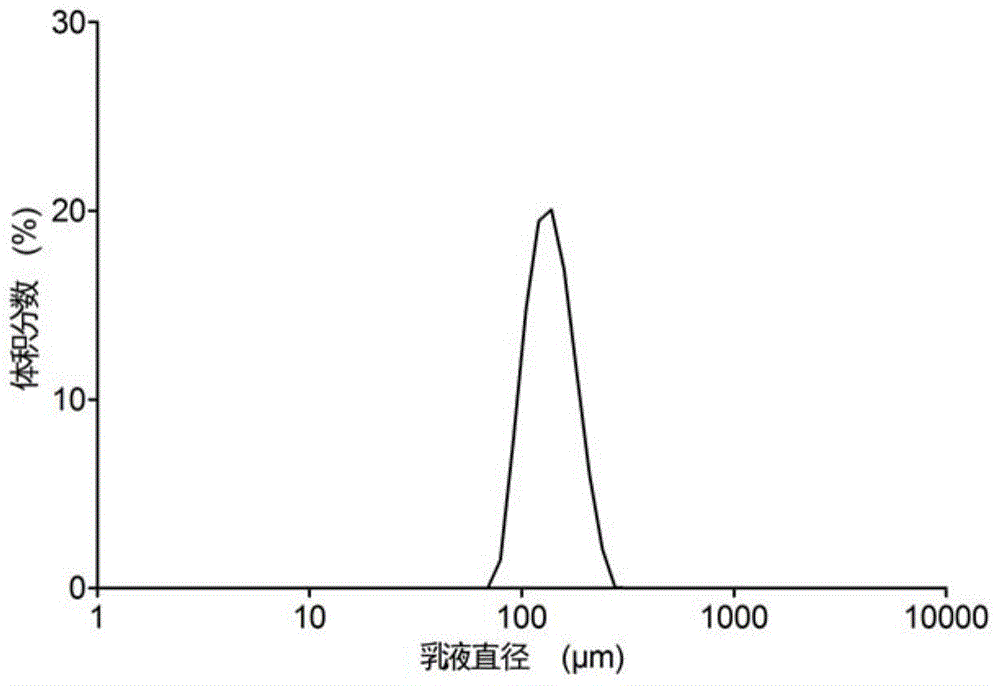

Embodiment 1

[0106] Accurately weigh 0.5g of polylactic acid-glycolic acid copolymer (LA / GA75 / 25) particles, the molecular weight is 5kDa, the particle size is 10nm, 100nm, 500nm, 1μm, 10μm, 20μm, add 50mL of water phase to make it evenly dispersed , to obtain an aqueous suspension with a particle concentration of 1% (w / v). The pH of the aqueous phase is 8. Add 12.5 mL of hexadecane to the membrane emulsification device, and the oil-water ratio is 1:4. The device is equipped with an SPG membrane (distribution coefficient 15%) with a membrane pore size of 200 μm, which is submerged in the water phase. The nitrogen pressure is 0.1 kPa, the oil phase is pressed out through the SPG membrane, and directly enters the water phase, and a uniform emulsion is formed at a stirring rate of 50 rpm. Due to the biodegradability of polylactic acid-glycolic acid, the stability of the emulsion was studied by the emulsion centrifugation method, that is, the emulsion was centrifuged for 10 minutes under the...

Embodiment 2

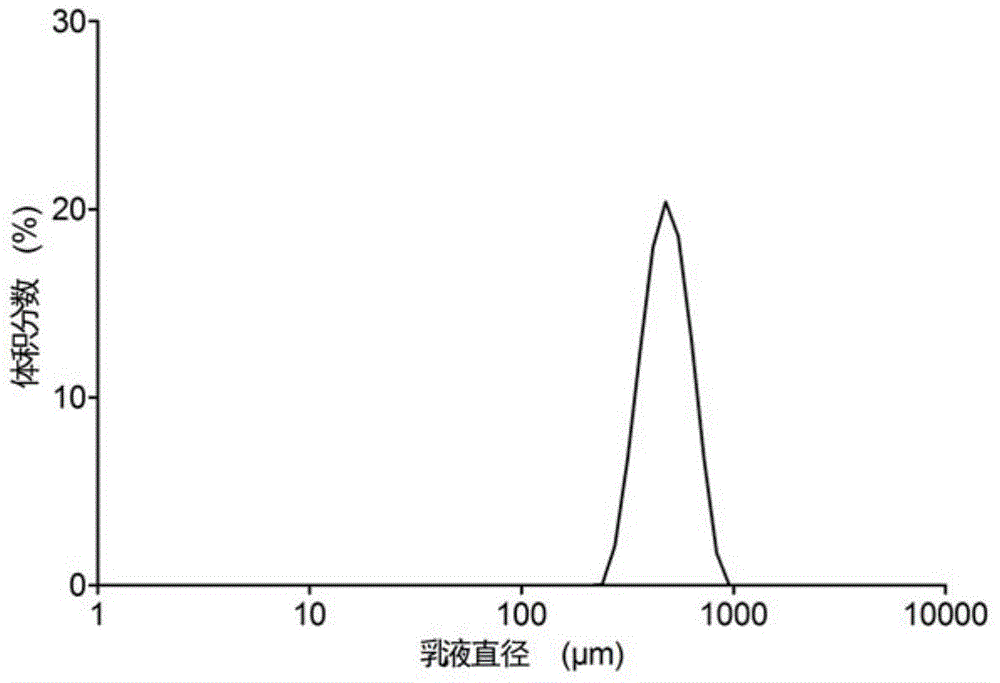

[0110] Accurately weigh 0.5g polylactic acid-glycolic acid copolymer (LA / GA75 / 25) particles, its molecular weight is 5kDa, particle diameter is 100nm, add 50mL water phase, make it disperse evenly, obtain particle concentration to be 1% (w / v) an aqueous suspension. The pH of the aqueous phase is 8. Add 12.5 mL of hexadecane to the membrane emulsification device, and the oil-water ratio is 1:4. The device was equipped with a polytetrafluoroethylene membrane (distribution coefficient 20%) with a pore size of 200 μm, which was submerged in the water phase. The nitrogen pressure is 0.1kPa, the oil phase is pressed out through the polytetrafluoroethylene membrane, and directly enters the water phase, and a uniform emulsion is formed at a stirring rate of 50rpm. The emulsion type is O / W type, and the average particle size is 500μm. The CV is 13.1%. The emulsion particle size distribution is as figure 2 shown.

[0111] Due to the biodegradability of poly(lactic-co-glycolic aci...

Embodiment 3

[0113] Accurately weigh 0.5g polylactic acid-glycolic acid copolymer (LA / GA50 / 50) particles, its molecular weight is 200kDa, particle diameter is 100nm, add 50mL aqueous phase, make it disperse evenly, obtain particle concentration to be 1% (w / v) an aqueous suspension. The pH of the aqueous phase is 8. Add 12.5 mL of hexadecane to the membrane emulsification device, and the oil-water ratio is 1:4. The device is equipped with an SPG membrane (distribution coefficient 15%) with a membrane pore size of 200 μm, which is submerged in the water phase. The nitrogen pressure is 0.1kPa, the oil phase is pressed out through the SPG membrane, and directly enters the water phase, and a uniform emulsion is formed at a stirring rate of 50rpm. The emulsion type is O / W type, the average particle size is 500μm, and the CV is 13.4 %.

[0114] Due to the biodegradability of polylactic acid-glycolic acid, the emulsion stability was studied by emulsion centrifugation. After centrifugation und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com