Solid-state avermectin particle preparation and preparation method and application thereof

An abamectin and solid state technology, applied in the field of solid abamectin particulate preparation and preparation thereof, can solve the problems of occurrence of phytotoxicity, poor control effect, and high energy consumption of the preparation process of the grinding method, and achieves the solution of unstable problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

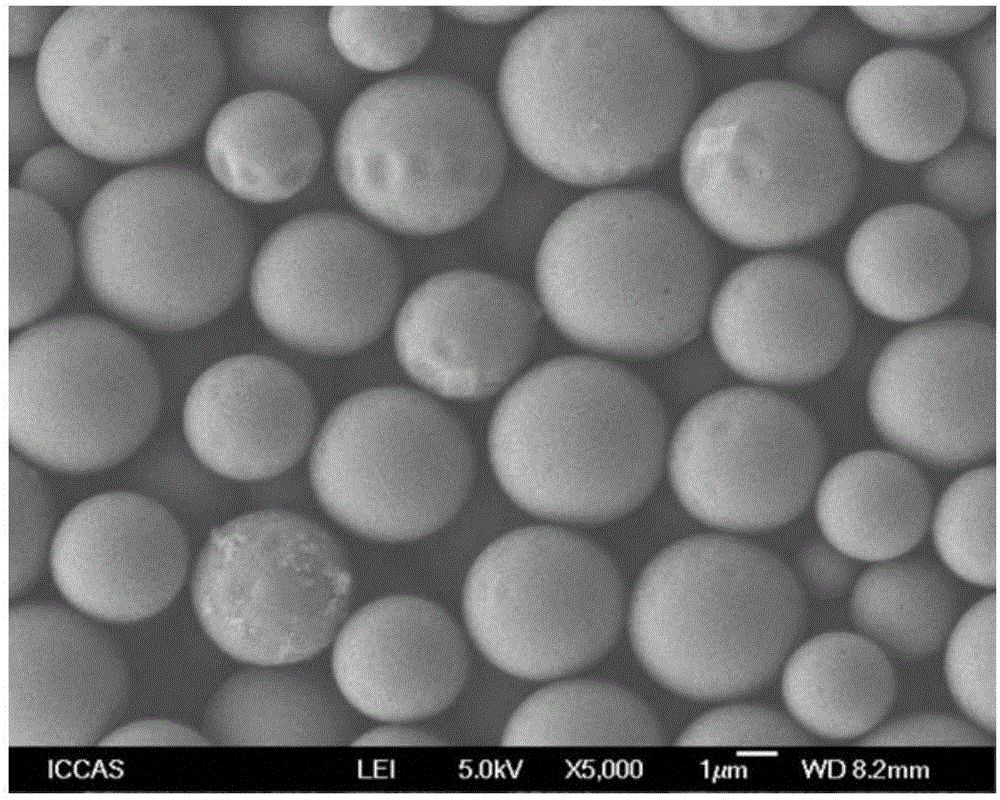

[0080] Embodiment 1, preparation solid-state Abamectin microsphere

[0081] (1) The drug avermectin was dissolved in dichloromethane, and configured into a 50 mg / mL solution as the oil phase.

[0082] (2) Dissolving polyvinyl alcohol with a number average molecular weight of 30,000 to 70,000 in water to prepare a 1.0% polyvinyl alcohol aqueous solution as the external water phase.

[0083] (3) After the oil phase obtained in step (1) is mixed with the external water phase obtained in step (2) according to the volume ratio of 1:20, mechanically stir at a stirring speed of 400 rpm for 1 min to obtain oil-in-water primary emulsion.

[0084] (4) Pour the primary emulsion system obtained in step (3) into the storage tank of the rapid membrane emulsification device, and pass through the membrane (9.0 microns in pore size) 3 times under 80 kPa nitrogen pressure to obtain a homogeneous oil-in-water emulsion.

[0085] (5) Stir the oil-in-water emulsion obtained in step (4) at room te...

Embodiment 2

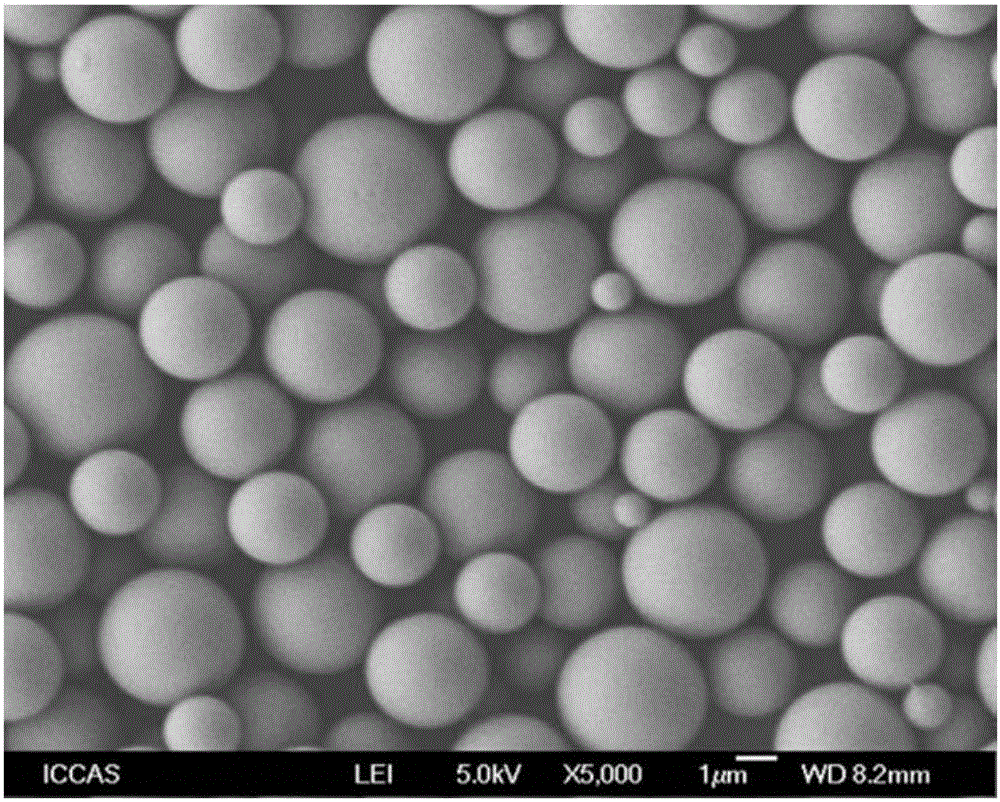

[0087] Embodiment 2, preparation solid-state Abamectin microsphere

[0088] (1) The drug avermectin was dissolved in dichloromethane, and configured into a 30 mg / mL solution as the oil phase.

[0089] (2) Dissolving polyvinyl alcohol with a number average molecular weight of 30,000 to 70,000 in water to prepare a 2.0% polyvinyl alcohol aqueous solution as the external water phase.

[0090] (3) After the oil phase obtained in step (1) is mixed with the external water phase obtained in step (2) according to the volume ratio of 1:35, mechanically stir at a stirring speed of 50 rpm for 6 minutes to obtain oil-in-water primary emulsion.

[0091] (4) Pour the mixed emulsion system obtained in step (3) into the storage tank of the rapid membrane emulsification device, and pass through the membrane (7.0 microns in aperture) 5 times under 100 kPa nitrogen pressure to obtain an oil-in-water emulsion with uniform particle size.

[0092] (5) Stir the oil-in-water emulsion obtained in st...

Embodiment 3

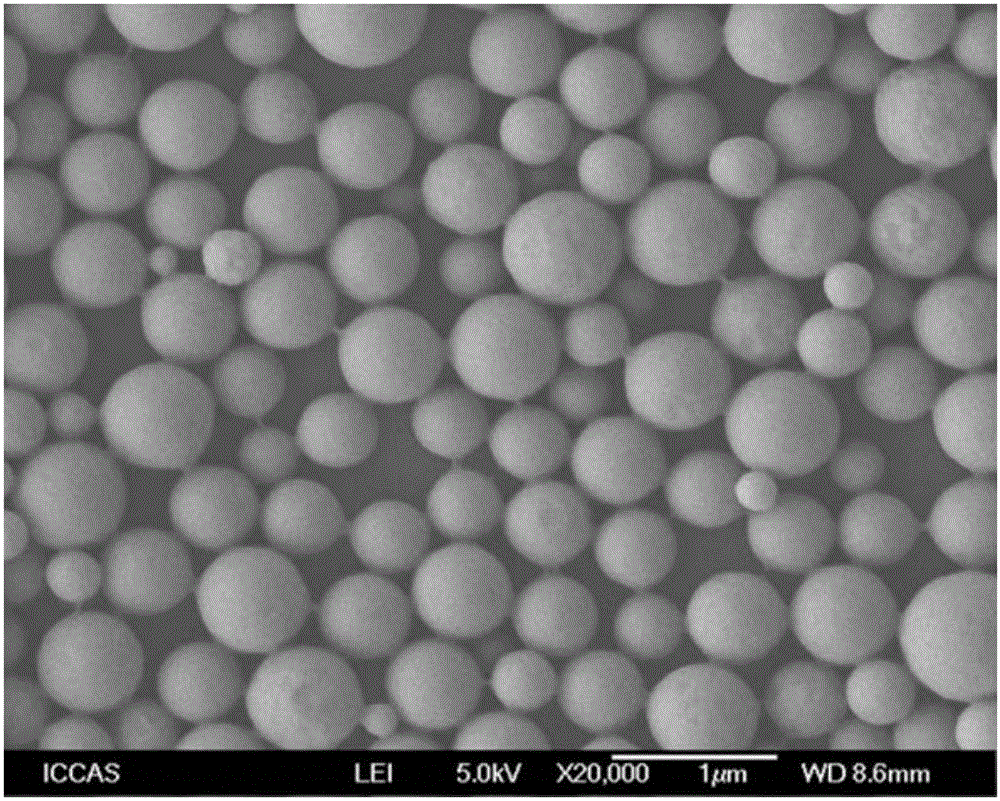

[0094] Embodiment 3, preparation solid-state Abamectin microsphere

[0095] (1) The drug avermectin was dissolved in dichloromethane to form a 20 mg / mL solution as the oil phase.

[0096] (2) Dissolving polyvinyl alcohol with a number average molecular weight of 30,000 to 70,000 in water to prepare a 1.0% polyvinyl alcohol aqueous solution as the external water phase.

[0097] (3) After the oil phase obtained in step (1) is mixed with the external water phase obtained in step (2) according to the volume ratio of 1:10, mechanically stir for 2 minutes at a stirring speed of 200 rpm to obtain oil-in-water primary emulsion.

[0098] (4) Pour the mixed emulsion system obtained in step (3) into the storage tank of the rapid membrane emulsification device, and pass through the membrane (2.5 microns in aperture) 5 times under a nitrogen pressure of 150 kPa to obtain an oil-in-water emulsion with uniform particle size.

[0099] (5) The oil-in-water emulsion obtained in step (4) was s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com