Method for preparing starch micro-capsules and microballons on basis of fast membrane emulsification method

A technology of starch microspheres and starch, which is applied in the direction of microsphere preparation, microcapsules, capsule transportation, etc., can solve the problems of complex and harsh conditions, uneven particle size of microspheres, and uneven size of microspheres, and achieve broad application prospects, Effect of Optimizing Particle Size Distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1, preparation oil-soluble starch microcapsule

[0056] The sulfated starch was dissolved in dichloromethane to make a 50 mg / mL solution. After mixing the above solution with water at a volume ratio of 1:1, ultrasonicate for 70 seconds at a power of 350W to obtain a water-in-oil primary emulsion. At a stirring speed of 2000 rpm, the primary emulsion was added to 50 times the volume of an aqueous polyvinyl alcohol solution with a mass concentration of 5%, and stirred for 10 minutes. The obtained pre-multiplex emulsion was poured into a rapid membrane emulsification device, and passed through the membrane 5 times under a nitrogen pressure of 1 MPa. The obtained water-in-oil-in-water multiple emulsion was stirred at room temperature for 12 hours at a speed of 160 rpm. The product was collected by centrifugation, washed several times with water, and freeze-dried. Microcapsules with an average particle diameter of 300 nanometers are obtained, and the microcapsu...

Embodiment 2

[0057] Embodiment 2, preparation oil-soluble starch microcapsule

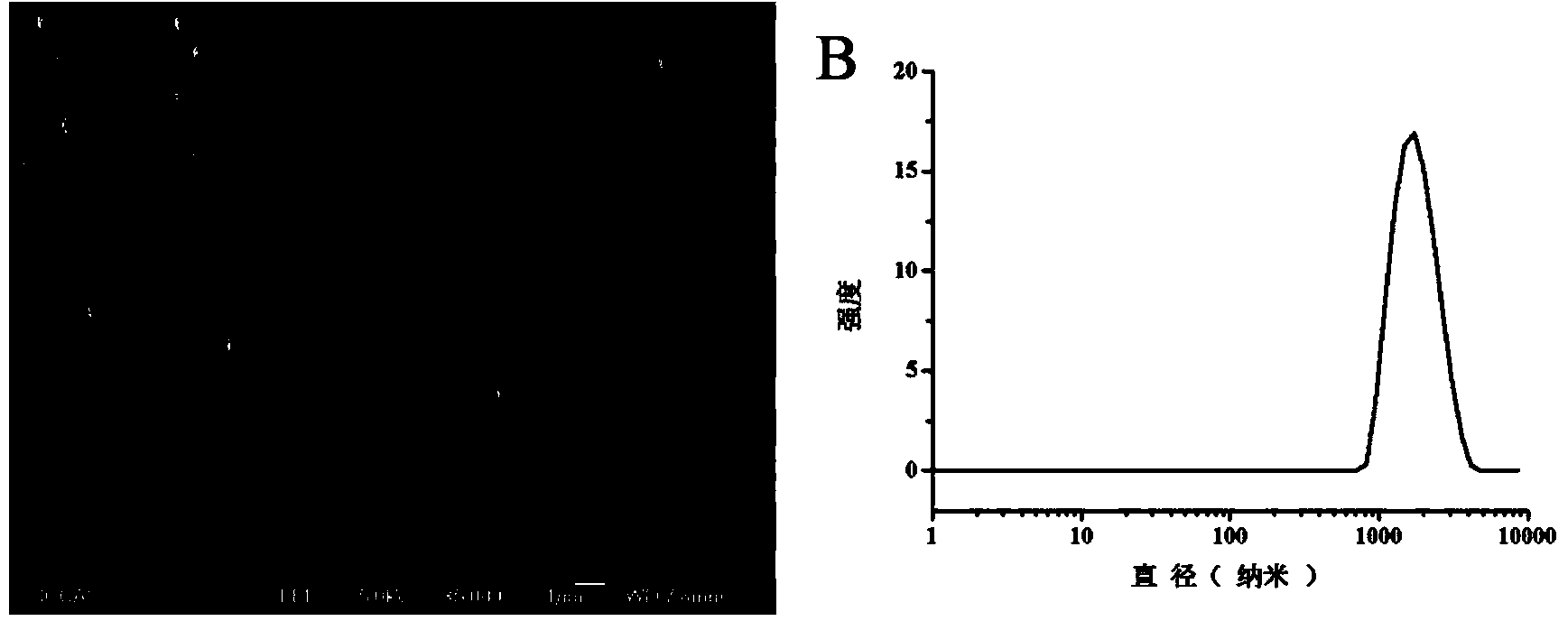

[0058] Dissolve acetate starch in ethyl acetate to make a 120 mg / mL solution. After mixing the above solution with water at a volume ratio of 10:1, ultrasonicate for 50 seconds at a power of 200W to obtain a water-in-oil primary emulsion. At a stirring speed of 1000 rpm, the primary emulsion was added to 15 times the volume of an aqueous polyvinyl alcohol solution with a mass concentration of 1%, and stirred for 2 minutes. The obtained pre-multiplex emulsion was poured into a rapid membrane emulsification device, and passed through the membrane 3 times under a nitrogen pressure of 0.1 MPa. The obtained water-in-oil-in-water multiple emulsion was stirred at room temperature for 12 hours at a speed of 260 rpm. The product was collected by centrifugation, washed several times with water, and freeze-dried. Obtaining a microcapsule with an average particle diameter of 1.5 microns, its corresponding scanning elect...

Embodiment 3

[0059] Embodiment 3, preparation oil-soluble starch microcapsule

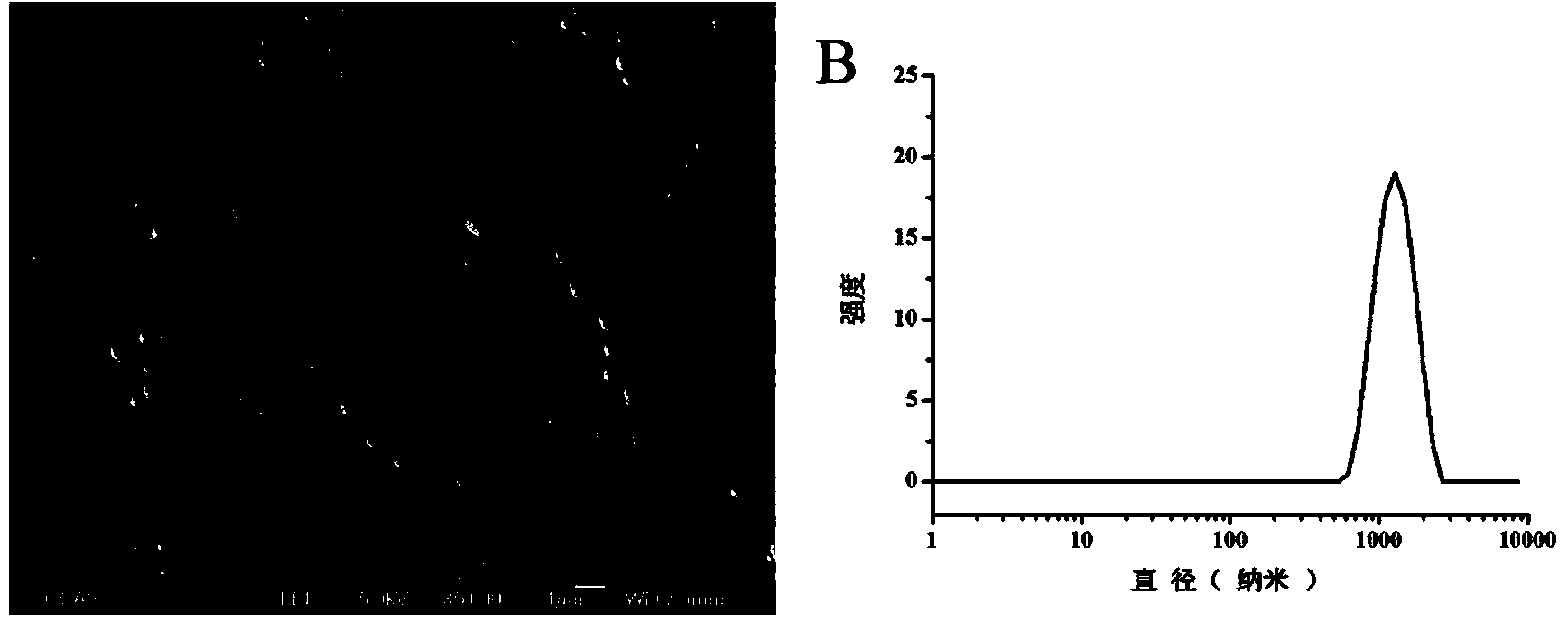

[0060] Formate starch was dissolved in dichloromethane to prepare a 150 mg / mL solution. After mixing the above solution with water at a volume ratio of 1:3, ultrasonication was performed for 90 seconds at a power of 300W to obtain a water-in-oil primary emulsion. At a stirring speed of 1500 rpm, the primary emulsion was added to 100 times the volume of an aqueous polyvinyl alcohol solution with a mass concentration of 3%, and stirred for 5 minutes. The obtained pre-multiplex emulsion was poured into a rapid membrane emulsification device, and passed through the membrane 5 times under a nitrogen pressure of 0.4 MPa. The obtained water-in-oil-in-water multiple emulsion was stirred at room temperature for 15 hours at a speed of 500 rpm. The product was collected by centrifugation, washed several times with water, and freeze-dried. Obtain the microcapsule that average particle size is 2 microns, and this microca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com