Functional nano-particle compound cross-linking microsphere powder as well as preparation method and application thereof

A nanoparticle and functional technology, which is applied in the field of monodisperse functional nanoparticle composite microsphere powder and its preparation, can solve the problem that the performance of functional particles is easily affected by the polymerization reaction environment, and there is no composite crosslinking of functional nanoparticles. The problems of phase separation of microspheres and microsphere structures can achieve the effects of accurate and reliable detection results, small coefficient of variation and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

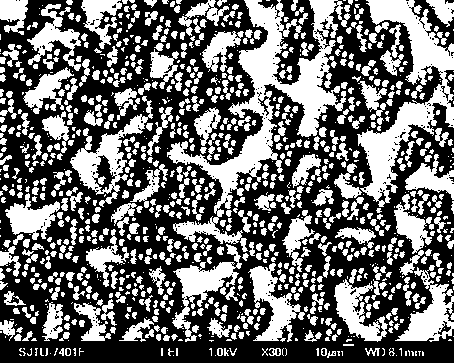

Image

Examples

Embodiment 1

[0067] Example 1 Preparation of Composite Crosslinked Microsphere Powder (1)

[0068] Styrene, divinylbenzene, methacrylic acid, benzoyl peroxide and CdSe / CdS quantum dots with an emission wavelength of 528 nm were dissolved in toluene, the concentration of styrene was 1 g / mL, and the concentration of divinylbenzene was 0.75g / mL, methacrylic acid concentration 0.5 g / mL, benzoyl peroxide concentration 0.001 g / mL, quantum dot concentration 1 nM / L, as the dispersed phase. A ceramic porous membrane with a pore size of 0.5 μm is used, and the dispersed phase is squeezed through the membrane by nitrogen at a pressure of 18 KPa, and then enters a water continuous phase containing an emulsifier SDS concentration of 1 wt.%, and the flow rate of the continuous phase is 0.30 m / s , to obtain an oil-in-water emulsion with uniform droplet size. The emulsion was heated to 70 °C and reacted for 12 h under the protection of nitrogen. After that, the obtained composite microsphere suspensio...

Embodiment 2

[0069] Example 2 Preparation of Composite Crosslinked Microsphere Powder (2)

[0070] Methyl acrylate, divinylbenzene, azobisisobutyronitrile and Fe 3 o 4 The magnetic nanoparticles were dissolved in chloroform with methyl acrylate concentration of 1 g / mL, divinylbenzene concentration of 0.5 g / mL, azobisisobutyronitrile concentration of 0.01 g / mL, Fe 3 o 4 The concentration of magnetic nanoparticles is 0.5 nM / L, which is used as the dispersed phase. The SPG porous membrane with a pore size of 5 μm is used, and the dispersed phase is squeezed through the membrane by nitrogen at a pressure of 21 KPa, and enters the water continuous phase containing the emulsifier SDS concentration of 0.5 wt.%, and the flow rate of the continuous phase is 0.40 m / s , to obtain an oil-in-water emulsion with uniform droplet size. The emulsion was heated to 70 °C and reacted for 12 h under the protection of nitrogen. Afterwards, the obtained microsphere suspension was centrifugally washed 3 ti...

Embodiment 3

[0071] Example 3 Preparation of Composite Crosslinked Microsphere Powder (3)

[0072] Styrene, divinylbenzene, methacrylic acid and NaYF 4 Rare earth nanoparticles were dissolved in xylene at a concentration of 1 g / mL for styrene, 0.5 g / mL for divinylbenzene, and 0.5 g / mL for methacrylic acid. NaYF 4 The concentration of rare earth nanoparticles was 1 nM / L, which was used as the dispersed phase. A SPG porous membrane with a pore size of 3 μm was used, and the dispersed phase was squeezed through the membrane by nitrogen at a pressure of 25 KPa, and then entered into a solution containing 0.001 g / mL initiator potassium persulfate, 0.5 wt.% emulsifier SDS and 0.5 wt.% Water continuous phase of stabilizer PVA, the flow velocity of the continuous phase is 0.35 m / s, and an oil-in-water emulsion with uniform droplet size is obtained. The emulsion was heated to 65 °C and reacted for 12 h under the protection of nitrogen. Afterwards, the obtained microsphere suspension was centr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com