Preparation process of composite preform

A composite material and preparation process technology, applied in the field of preparing composite material preforms by using alumina ceramic particles and tungsten carbide ceramic particles, can solve the problems of low toughness, fracture or peeling, shortened service life of components, etc., and improve wear resistance. , easy to operate, improve the effect of impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

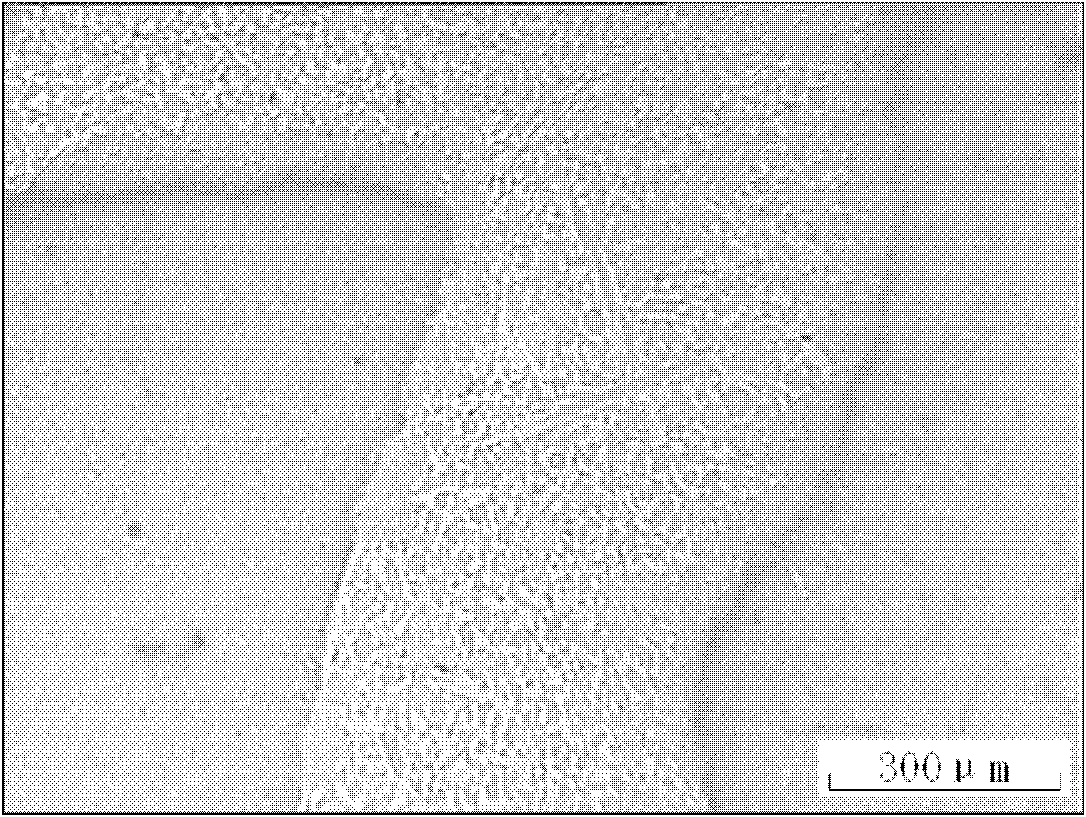

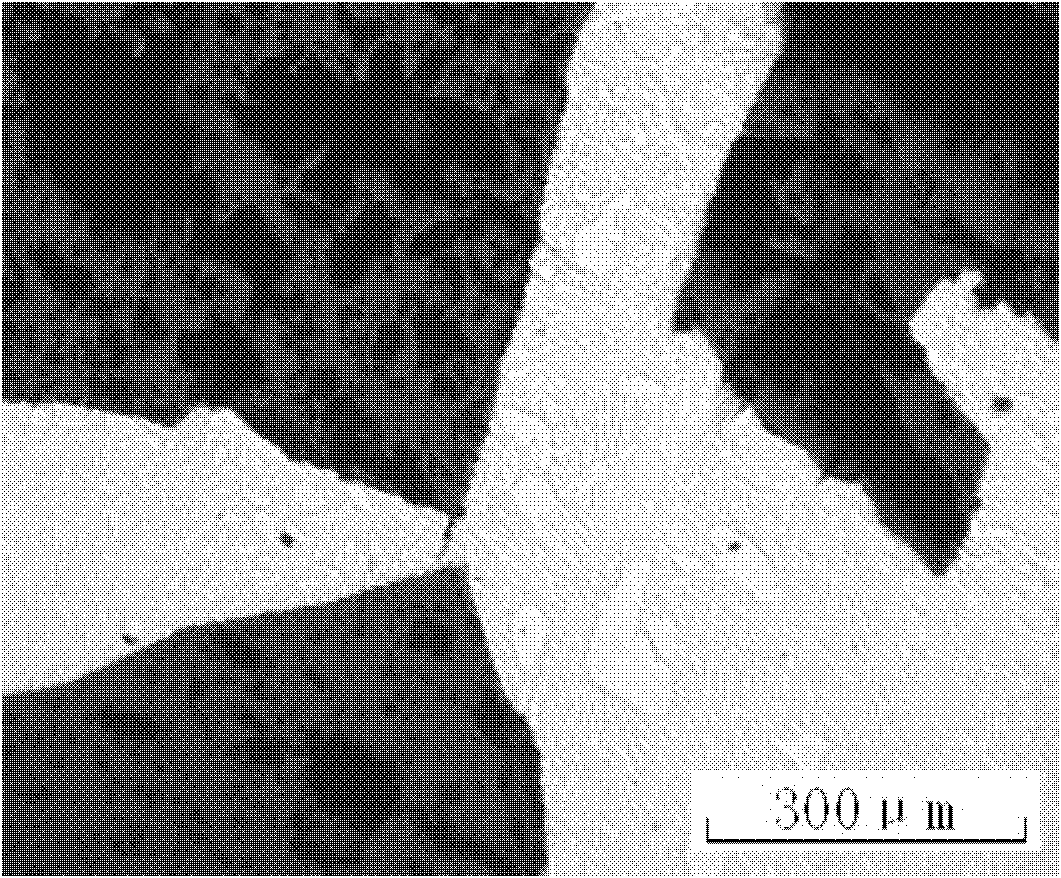

Image

Examples

Embodiment 1

[0022] 1) Firstly, mechanically mix the non-wetting ceramic particles and metal powder with the iron-based alloy with absolute ethanol to obtain a mixture, wherein the mass ratio of the non-wetting ceramic particles and metal powder with the iron-based alloy is 1:0.5, without The amount of water ethanol added is 2% of the mass of the ceramic particles, the particle size of the metal powder is 150-400 mesh, and the ceramic particle that does not infiltrate with the iron-based alloy is alumina with a particle size of 8-60 mesh;

[0023] 2) Next, the mixture is filled into a columnar graphite mold, and the particles are dried at 80°C for 30 minutes;

[0024] 3) Finally, put the dried particles together with the graphite mold into a vacuum sintering furnace for sintering. The vacuum degree is 0.01Pa, the sintering temperature is 1250°C, and the temperature is kept for 60 minutes. After cooling, the ceramic particles are embedded in the metal, and the overall structure is porous. C...

Embodiment 2

[0026] 1) First, mechanically mix the non-wetting ceramic particles and metal powder with absolute ethanol to obtain a mixture, wherein the mass ratio of the non-wetting ceramic particles and metal powder with the iron-based alloy is 1:0.8, without The amount of water ethanol added is 3% of the mass of the ceramic particles, the particle size of the metal powder is 150-400 mesh, and the ceramic particle that does not infiltrate with the iron-based alloy is BN with a particle size of 8-60 mesh;

[0027] 2) Next, fill the mixture into a graphite block mold and dry the particles at 80°C for 30 minutes;

[0028] 3) Finally, put the dried particles together with the graphite mold into a vacuum sintering furnace for sintering. The vacuum degree is 0.01Pa, the sintering temperature is 1280°C, and the temperature is kept for 50 minutes. After cooling, the ceramic particles are embedded in the metal, and the overall structure is porous. Composite preforms.

Embodiment 3

[0030] 1) First, mechanically mix the non-wetting ceramic particles and metal powder with the iron-based alloy with absolute ethanol to obtain a mixture, wherein the mass ratio of the non-wetting ceramic particles and metal powder with the iron-based alloy is 1:1.5, without The amount of water ethanol added is 5% of the mass of the ceramic particles, the particle size of the metal powder is 150-400 mesh, and the ceramic particle that does not infiltrate with the iron-based alloy is TiN with a particle size of 8-60 mesh;

[0031] 2) Next, fill the mixture into a honeycomb graphite mold, and dry the particles at 80°C for 30 minutes;

[0032] 3) Finally, put the dried particles together with the graphite mold into a vacuum sintering furnace for sintering. The vacuum degree is 0.01Pa, the sintering temperature is 1320°C, and the temperature is kept for 40 minutes. After cooling, the ceramic particles are embedded in the metal, and the overall structure is porous. Composite preform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com