A Liquid Injection Process for High Specific Energy Lithium-ion Batteries

A lithium-ion battery, high specific technology, applied in the direction of battery components, circuits, electrical components, etc., can solve the problems of long injection time and difficulty in injection of high specific energy lithium-ion batteries, so as to improve battery performance and shorten the The effect of liquid injection time and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

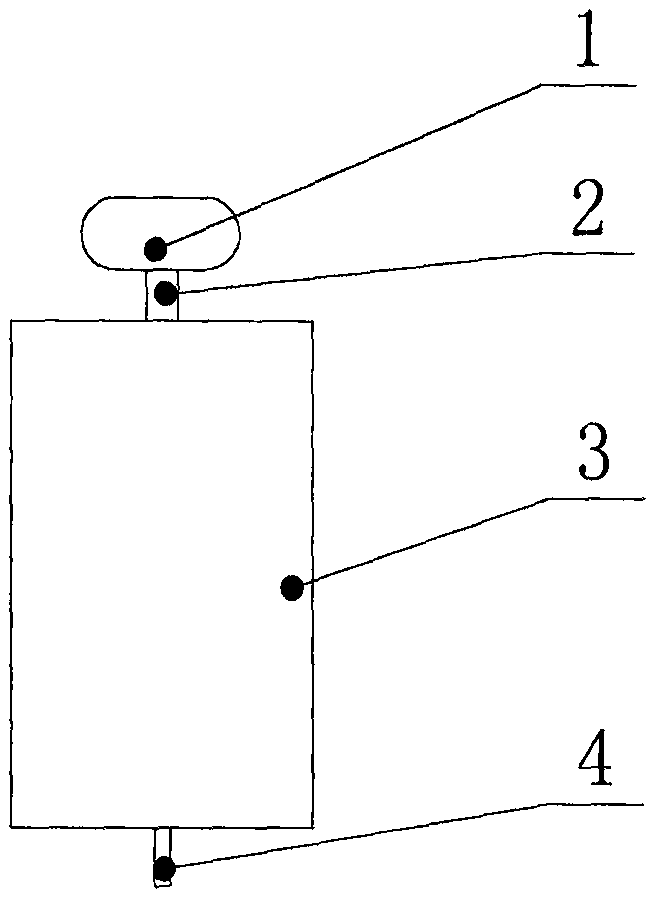

Image

Examples

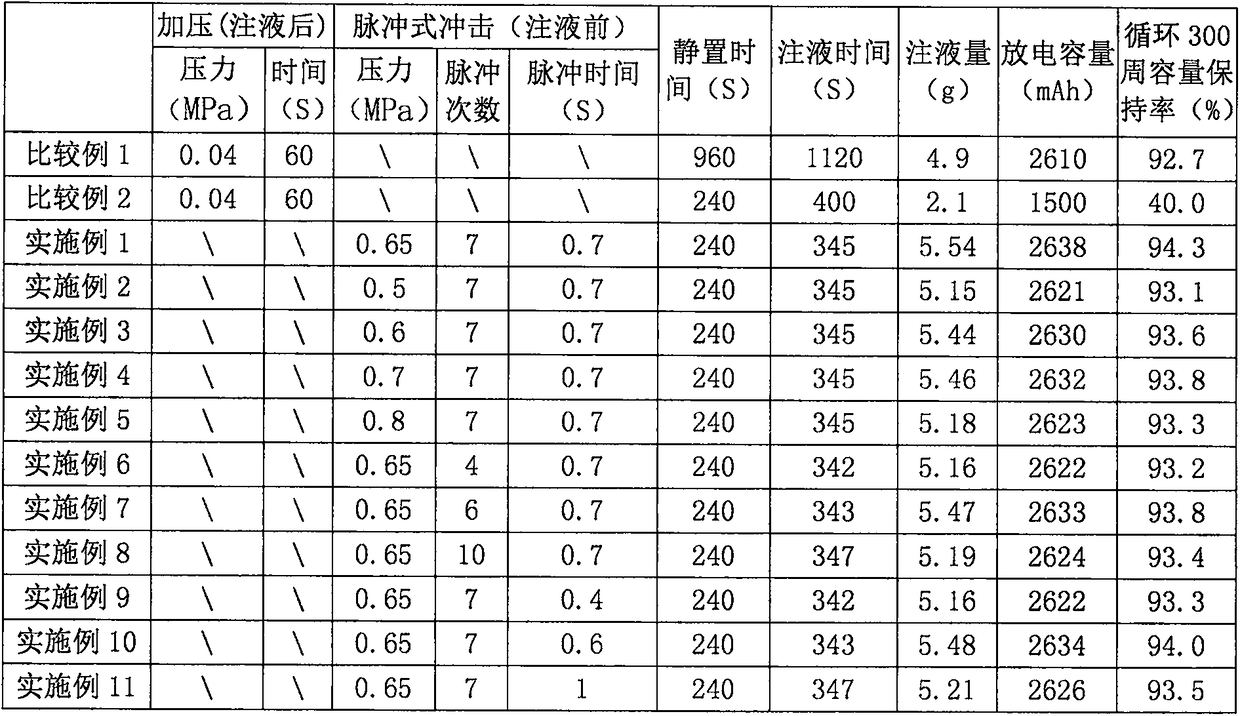

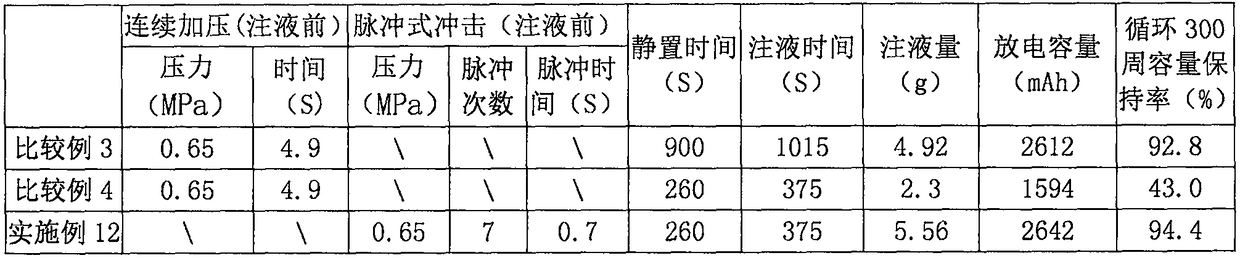

Embodiment 1

[0048] For "INR18650-2600mAh" battery injection, the electrolyte is made of LiPF 6(Concentration of 1 mole / liter) and additive vinylene carbonate (1%) are dissolved in ethylene carbonate / dimethyl carbonate / methyl ethyl carbonate=1:1:1 (volume ratio) mixed solvent to prepare . The liquid injection volume is designed to be 5.6g. After the battery is wound, assembled, dried, short-circuit tested and weighed, the liquid injection starts. The specific liquid injection steps: (1) Open and close the nitrogen port 7 times in a row, and the opening time of each nitrogen port is 0.7 S, nitrogen gas (0.65MPa) enters the liquid injection cup, high-pressure nitrogen gas pulses the liquid injection hole through the liquid injection nozzle, the number of pulses is 7 times, and the pulse time is 0.7S; (2) Vacuum until the vacuum degree reaches -0.085 MPa, keep 60S; (3) Open the liquid injection solenoid valve, inject electrolyte; (4) Stand still for 240S, take out the battery, seal and weigh...

Embodiment 2

[0050] For "INR18650-2600mAh" battery injection, the electrolyte is made of LiPF 6 (Concentration of 1 mole / liter) and additive vinylene carbonate (1%) are dissolved in ethylene carbonate / dimethyl carbonate / methyl ethyl carbonate=1:1:1 (volume ratio) mixed solvent to prepare . The liquid injection volume is designed to be 5.6g. After the battery is wound, assembled, dried, short-circuit tested and weighed, the liquid injection starts. The specific liquid injection steps: (1) Open and close the nitrogen port 7 times in a row, and the opening time of each nitrogen port is 0.7 S, nitrogen gas (0.5MPa) enters the liquid injection cup, and high-pressure nitrogen gas pulses the liquid injection hole through the liquid injection nozzle. The number of pulses is 7 times, and the pulse time is 0.7S; (2) Vacuum until the vacuum degree reaches -0.085 MPa, keep 60S; (3) Open the liquid injection solenoid valve, inject electrolyte; (4) Stand still for 240S, take out the battery, seal and w...

Embodiment 3

[0052] For "INR18650-2600mAh" battery injection, the electrolyte is made of LiPF 6 (Concentration of 1 mole / liter) and additive vinylene carbonate (1%) are dissolved in ethylene carbonate / dimethyl carbonate / methyl ethyl carbonate=1:1:1 (volume ratio) mixed solvent to prepare . The liquid injection volume is designed to be 5.6g. After the battery is wound, assembled, dried, short-circuit tested and weighed, the liquid injection starts. The specific liquid injection steps: (1) Open and close the nitrogen port 7 times in a row, and the opening time of each nitrogen port is 0.7 S, nitrogen gas (0.6MPa) enters the liquid injection cup, high-pressure nitrogen gas pulses through the liquid injection nozzle to the liquid injection hole, the number of pulses is 7 times, and the pulse time is 0.7S; (2) Vacuum until the vacuum degree reaches -0.085 MPa, keep 60S; (3) Open the liquid injection solenoid valve, inject electrolyte; (4) Stand still for 240S, take out the battery, seal and we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com