Needle for spinning

A technology of weaving and needle eye, which is applied in the direction of textiles and papermaking, machine needles, sewing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

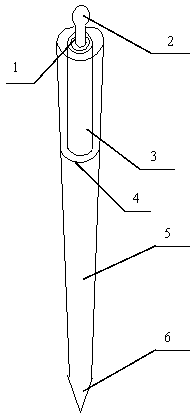

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. Such as figure 1 Shown: a needle for weaving, including a needle point 6 and a needle body 4, the needle body 4 includes a main body 5 and a tail 1, the tail 1 includes a needle eye 2, and one end of the main body 5 is provided with a groove 3 , the tail 1 is connected to the groove 3, the area of the needle eye 2 is 3-4 square millimeters, the depth of the groove 3 is 8mm, and the length of the tail 1 is 6-7mm, so that the tail is on the needle When passing through the textile, it can be shrunk in the groove of the main body, which effectively reduces the resistance when passing through, and will not damage the textile. Moreover, the problem of difficult penetration of the needle and thread is solved simply by enlarging the area of the needle eye. The structure is relatively It is much simpler and easier to produce.

[0015] It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com