Needle for spinning

A textile and needle technology, applied to textiles and papermaking, machine needles, sewing equipment, etc., can solve problems such as easy hooking of textiles, damage to textiles, and reduced work efficiency, so as to solve the problem of difficult penetration of needles and threads and reduce resistance , easy to produce and adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

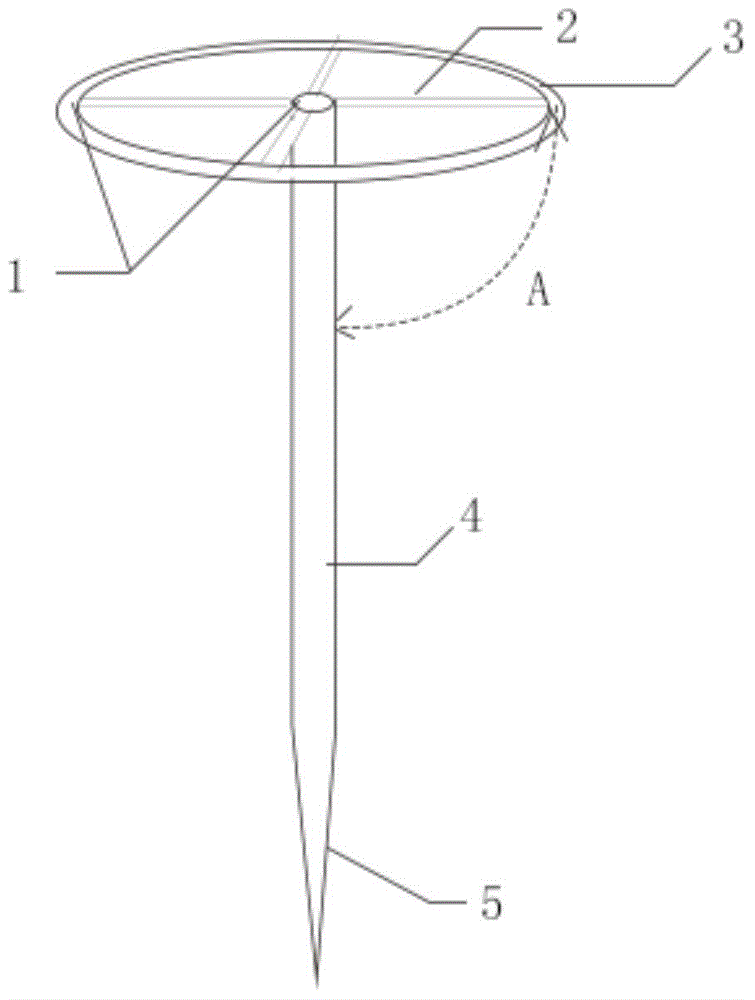

[0012] Such as figure 1 As shown, a needle for weaving includes a needle body and a needle tail, the needle body includes a needle point 5 and a main body 4, the needle tail includes a connecting rod 2, a needle eye ring 3, the main body 4 and the connecting rod 2 Connected by the connecting shaft 1, the needle eye ring 3 and the connecting rod 2 are connected by the connecting shaft 1, the length of the connecting rod 2 is 4-5mm, so that the needle body will not damage the textiles, and at the same time, it solves the problem that the needle thread is difficult to penetrate The problem is that the structure is relatively simple and the production is convenient.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com