Cooking utensil

A technology of cooking utensils and cooking chambers, applied in kitchen utensils, household utensils, roasters/barbecue grids, etc., can solve problems such as low utilization efficiency, high cost, and poor heat dissipation, and achieve efficient integration, guidance, and improvement Heat dissipation performance, effect of reducing drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

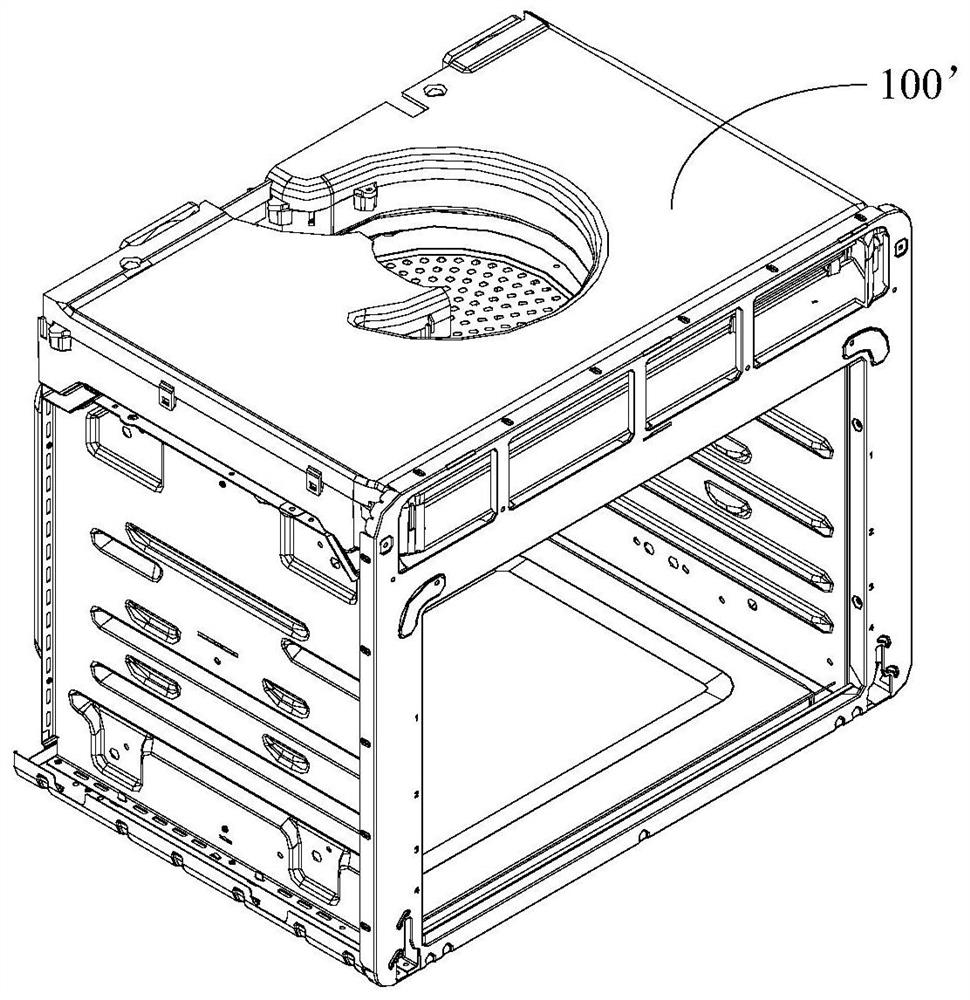

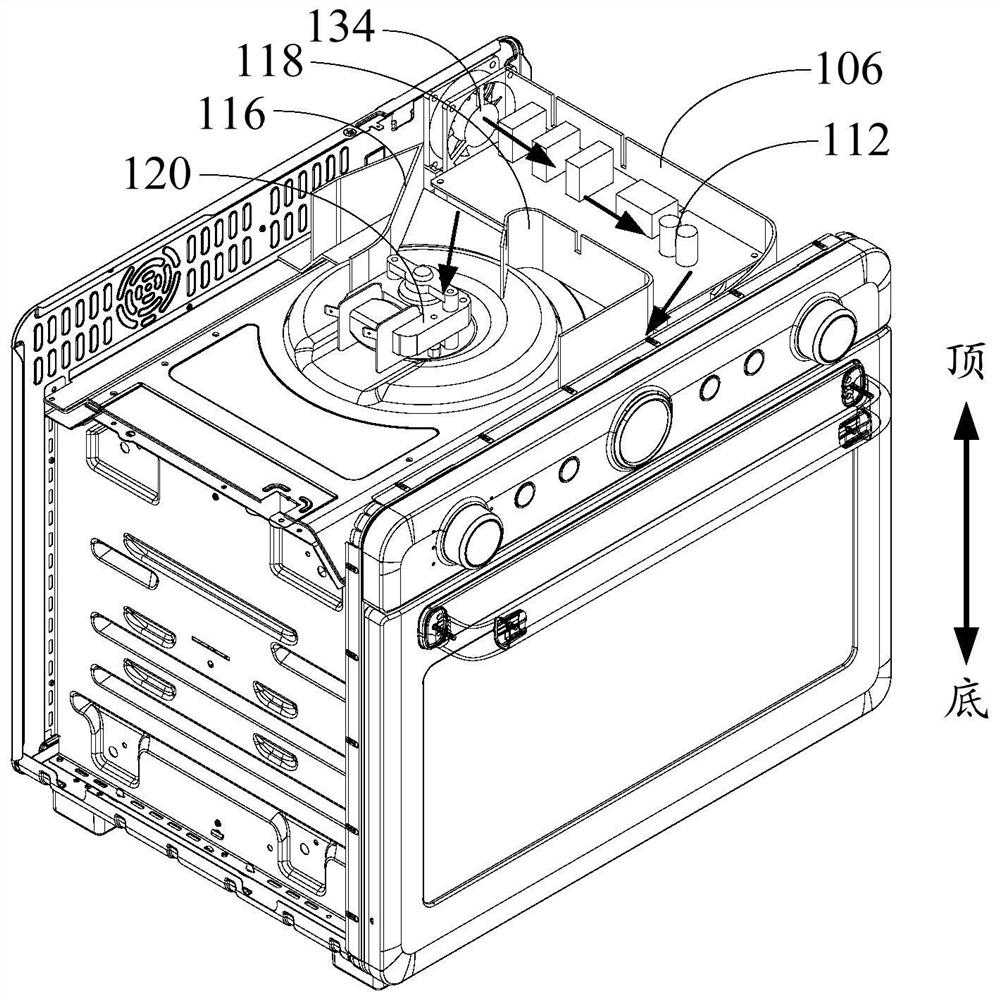

[0072] Such as image 3 and Figure 4 As shown, the first embodiment of the present invention proposes a cooking appliance, including: an air duct structure 100 ;

[0073] Among them, such as image 3 As shown, the airflow inside the air duct structure 100 can be discharged through the air outlet 104 , and the first side wall 106 extends toward the direction of the air outlet 104 , which can play a certain air guiding effect. In addition, since the bottom wall 102 is further provided with a flow guide 108 , and the flow guide 108 extends toward the air outlet 104 , and cooperates with the first side wall 106 to jointly play a role of flow guide.

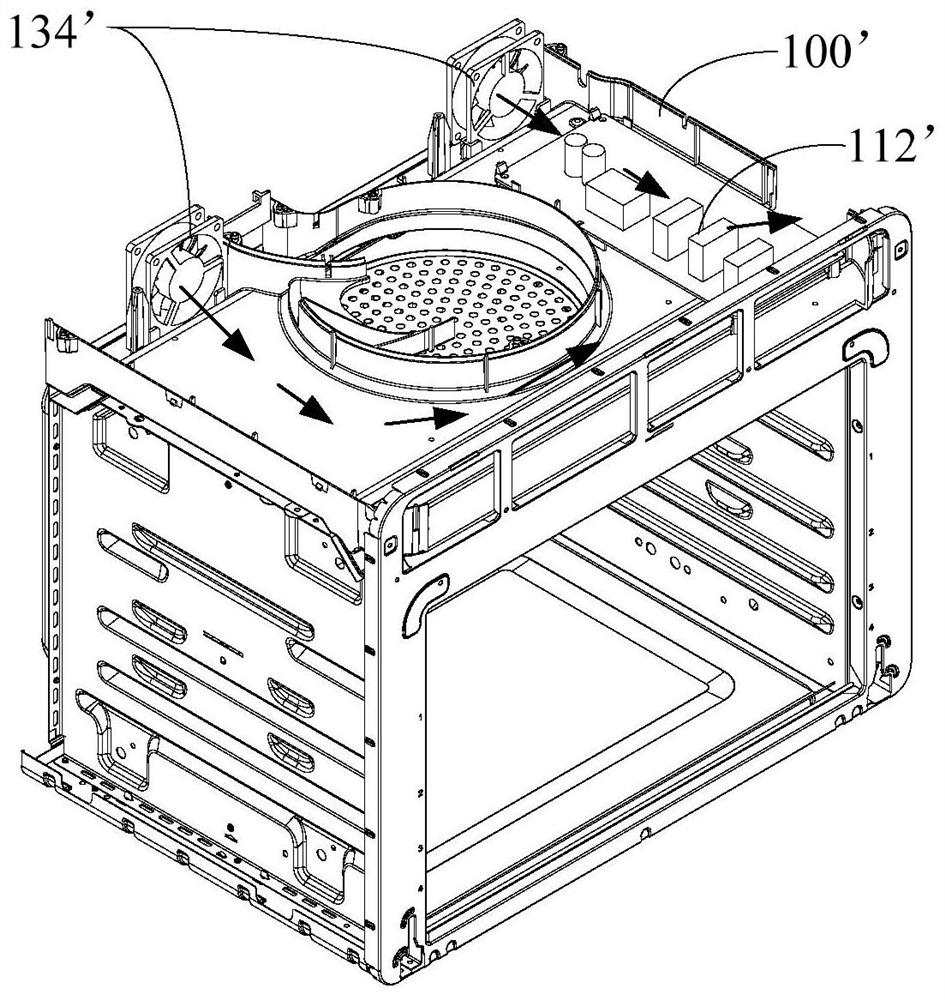

[0074] In particular, as Figure 4 As shown, the top of the air guide 108 is lower than the top of the first side wall 106, which makes it possible to assemble the heat sink 112 inside the air duct structure 100 during use, and assemble the heat sink 112 on the guide. Flow piece 108 on. With such a design, part of the airflow in...

Embodiment 2

[0078] Such as image 3 and Figure 4 As shown, the second embodiment of the present invention proposes a cooking utensil, including: an air duct structure 100 and a heat dissipation member 112; the air duct structure 100 includes a bottom wall 102, an air outlet 104, a first side wall 106, and a flow guide 108 and support 110.

[0079] Among them, such as image 3 As shown, the airflow inside the air duct structure 100 can be discharged through the air outlet 104 , and the first side wall 106 extends toward the direction of the air outlet 104 , which can play a certain air guiding effect. In addition, since the bottom wall 102 is further provided with a flow guide 108 , and the flow guide 108 extends toward the air outlet 104 , and cooperates with the first side wall 106 to jointly play a role of flow guide.

[0080] In addition, if Figure 4 As shown, the support member 110 is disposed on the bottom wall 102 and protrudes from the bottom wall 102 . In particular, the to...

Embodiment 3

[0086] Such as image 3 and Figure 4 As shown, the third embodiment of the present invention proposes a cooking utensil, including: an air duct structure 100 and a heat dissipation member 112; the air duct structure 100 includes a bottom wall 102, an air outlet 104, an air inlet 114, and a first side wall 106 , the deflector 108 and the support 110 .

[0087] Among them, such as image 3 As shown, the airflow inside the air duct structure 100 can be discharged through the air outlet 104 , and the first side wall 106 extends toward the direction of the air outlet 104 , which can play a certain air guiding effect. In addition, since the bottom wall 102 is further provided with a flow guide 108 , and the flow guide 108 extends toward the air outlet 104 , and cooperates with the first side wall 106 to jointly play a role of flow guide.

[0088] Moreover, when the heat dissipation element 112 is assembled on the support element 110 of the air duct structure 100, the first side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com