Ceramic particle reinforced composite wear-resistant part and preparation method thereof

A technology of reinforced composite and ceramic particles, which is applied in the field of hammer heads of crushers, and can solve problems affecting the quality of castings, difficult penetration of molten metal, fracture or peeling of composite materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

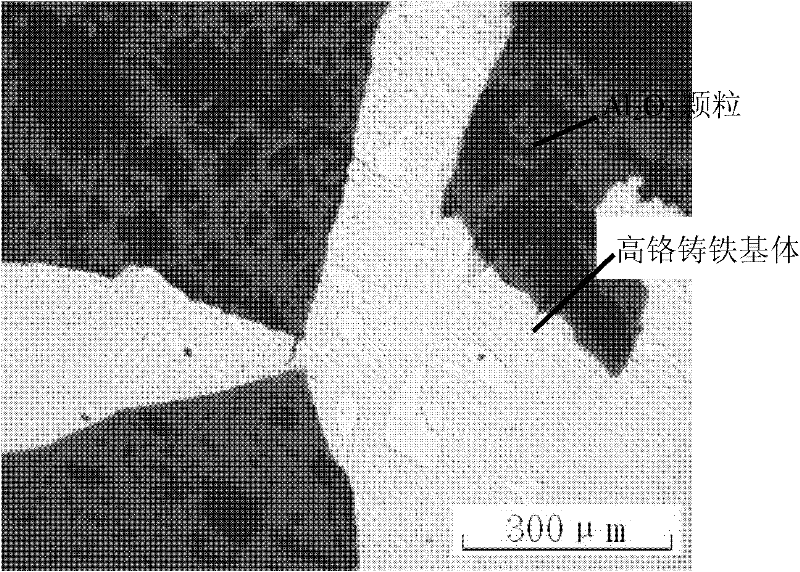

[0027] Example 1: hammer crusher hammer

[0028] 1) First, mix alumina ceramic particles with a particle size of 8-60 mesh and high-manganese steel metal powder with a particle size of 150-400 mesh with absolute ethanol to obtain a mixture, wherein the mass ratio of oxide ceramic particles to metal powder 1:0.8, the addition of absolute ethanol is 3% of the oxide ceramic particles;

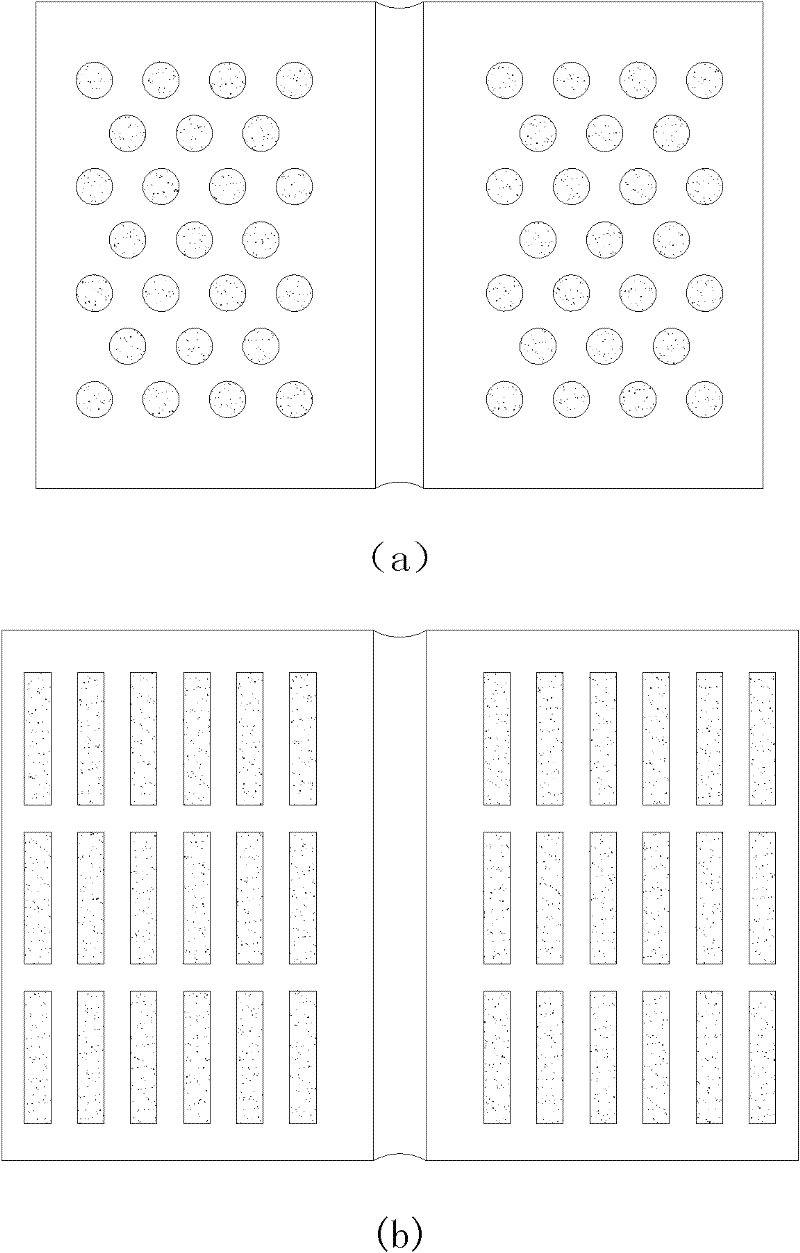

[0029] 2) Then, fill the mixture into a columnar, strip-shaped or honeycomb graphite mold. In order to prevent the mold from sticking, a layer of graphite paper with a thickness of 0.4-0.6mm is placed between the mixed particles and the mold, and dried at 80°C The mixture is mixed particles, and then the mold and the mixed particles are put into a vacuum sintering furnace for sintering at 1300 ° C and a vacuum degree of 0.1 Pa for 45 minutes, and the metal powder bonds the ceramic particles together to form a prefabricated body;

[0030] 3) After cooling, open the mold, take out the sintered pref...

Embodiment 2

[0032] Example 2: hammer crusher hammer head

[0033] 1) First, uniformly mix zirconia ceramic particles with a particle size of 8-60 mesh and alloy steel metal powder with a particle size of 150-400 mesh with absolute ethanol to obtain a mixture, wherein the mass ratio of the oxide ceramic particles to the metal powder is 1:0.5, the addition of absolute ethanol is 4% of the oxide ceramic particles;

[0034]2) Then, the mixture is filled in a block graphite mould. In order to prevent the mold from sticking, a layer of graphite paper with a thickness of 0.4 to 0.6mm is placed between the mixed particles and the mold, and the mixture is dried at 80°C to obtain the mixed particles, and then Put the mold together with the mixed particles into the vacuum sintering furnace and sinter for 50 minutes at 1280°C and a vacuum of 0.1 Pa. The metal powder bonds the ceramic particles together to form a prefabricated body;

[0035] 3) After cooling, open the mold, take out the sintered pref...

Embodiment 3

[0037] Embodiment 3: vertical cement grinding roller

[0038] 1) First, mix alumina ceramic particles with a particle size of 8-60 mesh and high-manganese steel metal powder with a particle size of 150-400 mesh with absolute ethanol to obtain a mixture, wherein the mass ratio of oxide ceramic particles to metal powder 1:1.5, the addition of absolute ethanol is 4.2% of the oxide ceramic particles;

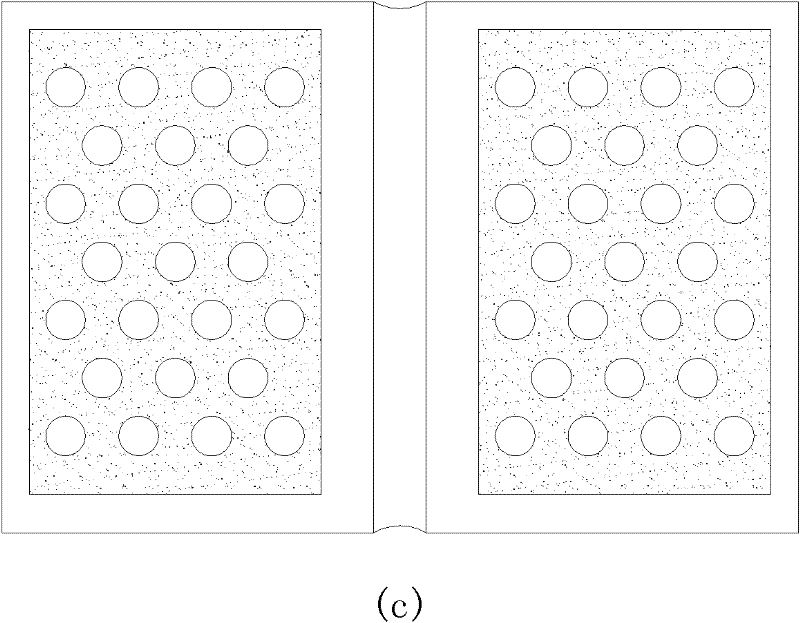

[0039] 2) Then, the mixture is filled in a honeycomb graphite mould. In order to prevent sticking to the mould, a layer of graphite paper with a thickness of 0.4 to 0.6mm is placed between the mixed particles and the mold, and the mixture is dried at 80°C to obtain the mixed particles, and then Put the mold together with the mixed particles into a vacuum sintering furnace and sinter for 30 minutes at 1350°C and a vacuum of 0.1 Pa. The metal powder bonds the ceramic particles together to form a prefabricated body;

[0040] 3) After cooling, open the mold, take out the sintered prefa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com