Bunchy yarn, its spinning method and special spinning frame

A yarn and slub technology, which is applied to spinning machines, yarn, textiles and papermaking, etc., can solve problems such as single variety, inability to spin slub yarn, easy separation of core and covered wires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

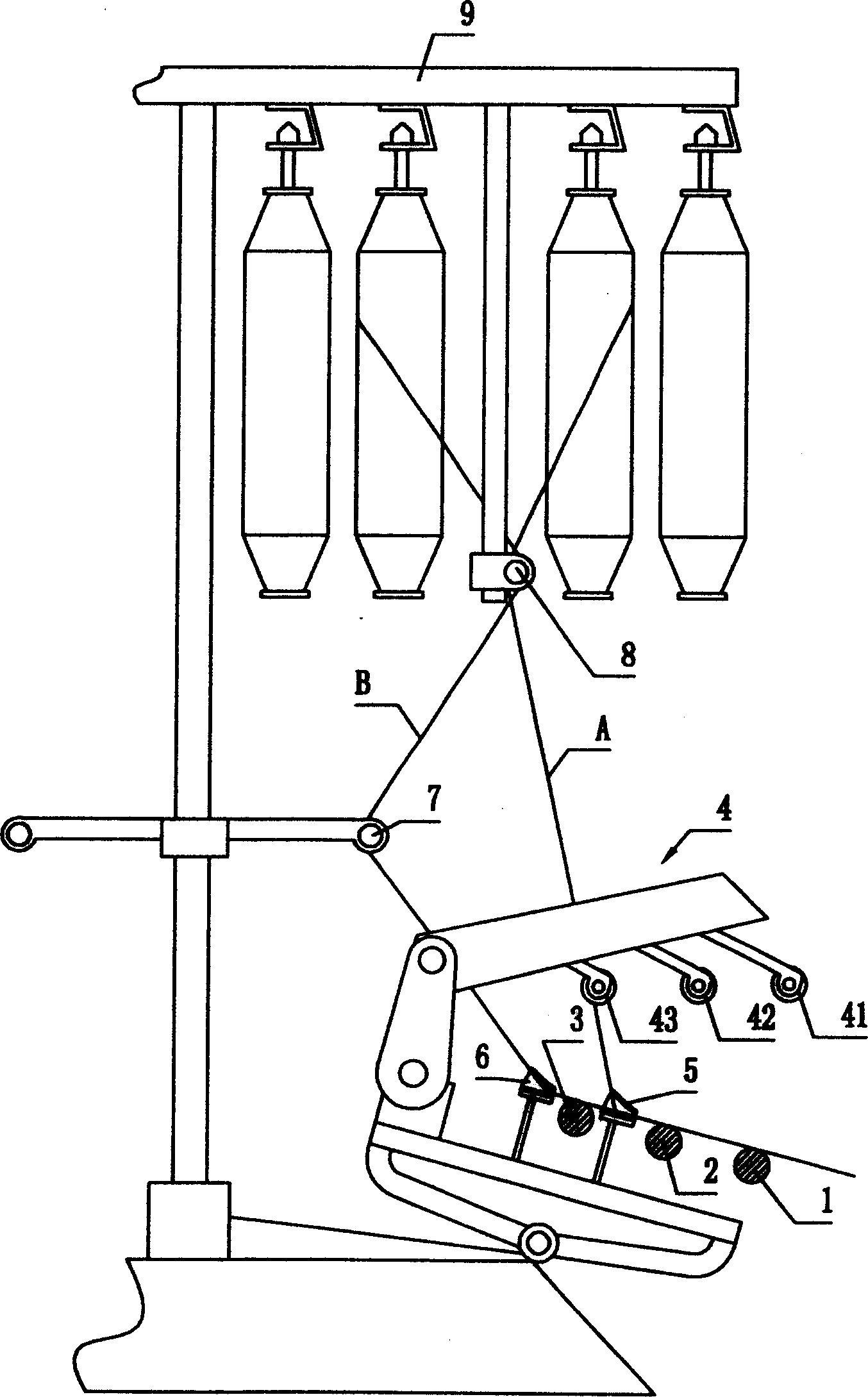

[0012] An improved spinning frame is improved on the basis of A513 type spinning frame. Such as figure 1 Shown, comprise feeding device, and this feeding device comprises front, middle, rear roller 1,2,3 and cradle 4; Front, middle and rear top roller 41,42,43 are installed on this cradle 4, above-mentioned The top roller presses the fed fiber on the front, middle and rear rollers 1, 2 and 3 respectively, forming a drafting front area between the front and middle rollers 1 and 2, and forming a draft zone between the middle and rear rollers 2 and 3. Stretching area; the feeding front side of the rear roller 3 is provided with a rear bell mouth cotton collector 6; the feeding front side of the middle roller 2 is provided with a middle bell mouth cotton collector 5. A spindle hanger support 9 is arranged above the spinning frame, and first and second guide rods 7 and 8 are arranged between the hanger hanger support 9 and the feeding device.

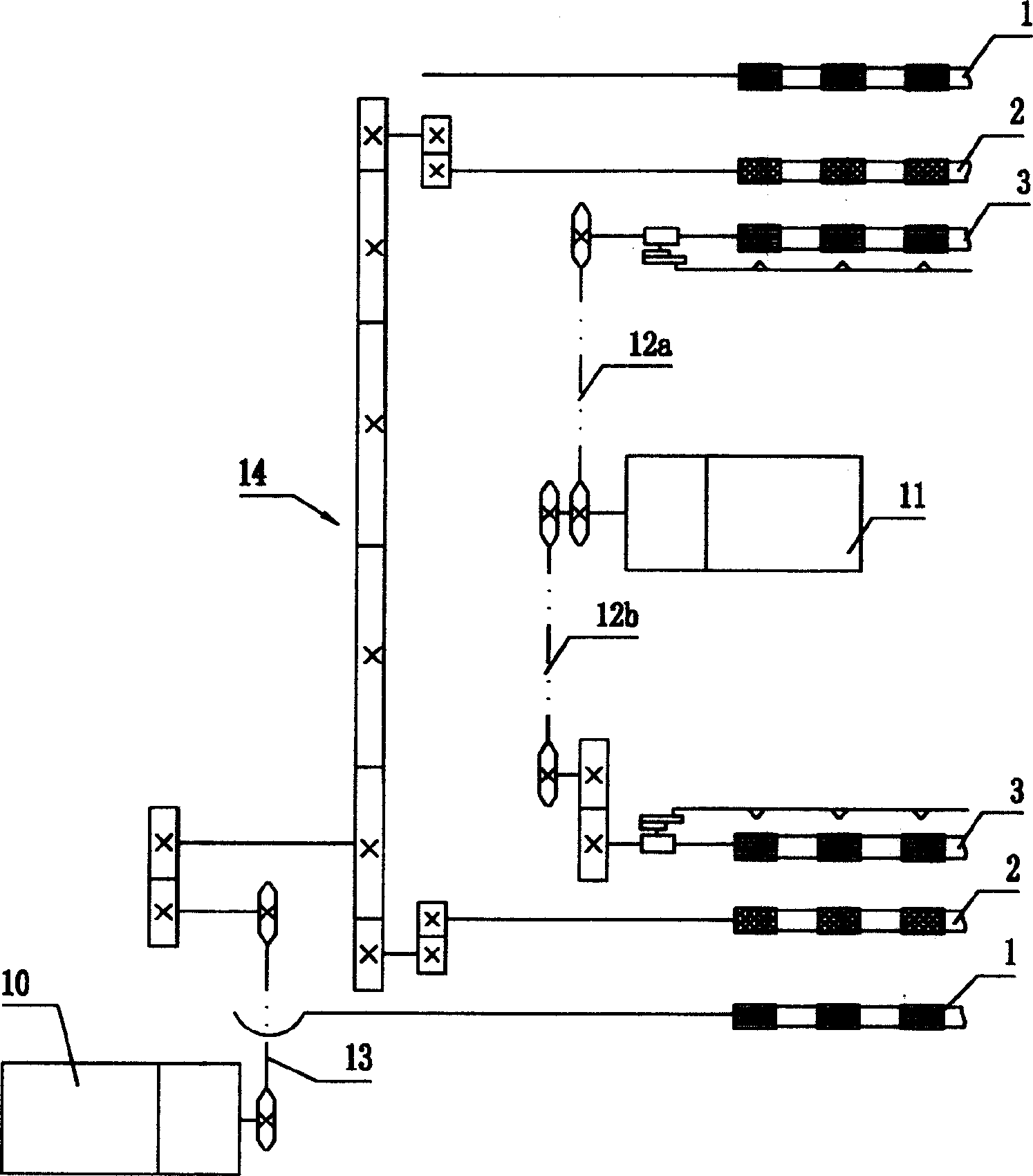

[0013] Such as figure 2 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com