Biological manure recovery device

A recovery device and feces technology, applied in the direction of biofuels, chemicals for biological control, biocides, etc., can solve the problem that the traditional activated sludge method cannot meet the discharge standards, the efficiency of nitrogen and phosphorus removal cannot be further improved, and sewage treatment Poor quality and other problems to achieve the effect of improving usability and feasibility, reducing harm to the human body, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

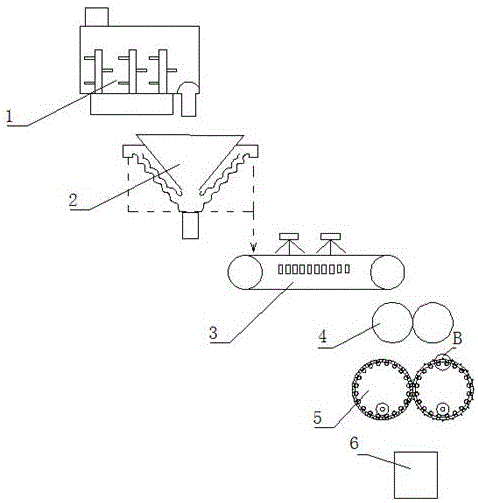

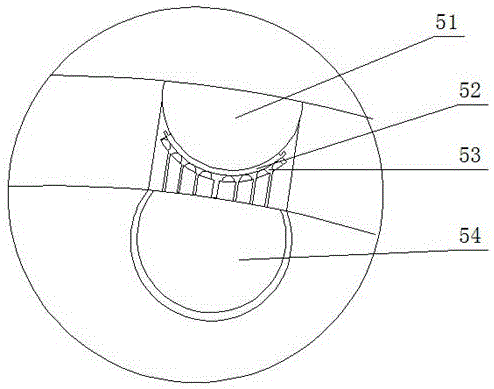

[0030] like figure 1 As shown, the biological feces recovery device of the present invention includes a crushing mechanism 1, a centrifugal mechanism 2, a drying mechanism 3, a compacting mechanism 4, a forming mechanism 5, and a collecting mechanism 6; the centrifugal mechanism 2 is used for centrifugal dehydration and will be dehydrated The material is transferred to the centrifugal mechanism 2; the compacting mechanism 4 includes two matching squeeze rollers, which compress the dried material into a strip shape and transfer the strip-shaped material to the forming mechanism 5, and the forming mechanism It includes two opposite forming rollers, the surface of the forming rollers has a mold cavity 51, and the two forming rollers cooperate with each other to extrude the material into shape. The structure dries and solidifies the feces, thereby ensuring the recovery of biological feces, reducing the pollution of rivers and water by biological feces, improving the recycling and ...

Embodiment 2

[0038] The biological excrement recovery device in embodiment 1, its recovery method is:

[0039] Step 1: Put fresh biological feces, straw, and water into the crushing mechanism 1 to crush and stir for 12-15 minutes to obtain a mixture, the water content in the mixture is 78-80%, and the average particle size is 6-8mm;

[0040] Step 2: Put the mixed material into the centrifugal mechanism 2, and make the mixed material undergo centrifugation and dehydration for 4-6 minutes, so that the water content in the mixed material will be 40-45%;

[0041] Step 3: Put the dehydrated mixture into the drying mechanism 3 and spread it evenly to a thickness of 1-1.3cm; use an open flame at 550-600°C to dry the lower part of the mixture for 20-30s to make the content of the mixture The water volume will be 20-24%;

[0042] Step 4: put the mixture into the compacting mechanism 4, and extrude the mixture into a strip with a thickness of 1-1.5cm under a pressure of 300-350kPa;

[0043] Step 5...

Embodiment 3

[0048] In the biological feces recovery device in embodiment 1, the ceramic sheet adopted by the conveyor belt comprises a reinforcement layer, a braided layer, and a ceramic layer from the inside and outside, and the reinforcement layer is made up of the following materials by weight: 12 parts of iron, 0.3 parts of carbon, 0.4 parts of aluminum, 1 part of silicon, and 0.3 parts of nickel; the braiding layer is made of the following materials by weight: 3 parts of iron wire, 1 part of aluminum wire, 1.5 parts of glass fiber, and 2 parts of ceramic fiber; the ceramic layer is made of the following materials Composition: 16 parts of vermiculite, 20 parts of sepiolite, 3 parts of iron slag, 9 parts of perlite, 6 parts of calcium oxide, 8 parts of alumina, 40 parts of ceramic powder, 16 parts of glass powder, 2 parts of bentonite, 7 parts Nickel-chromium alloy, 10 parts lithium oxide, 13 parts expanded perlite, 15 parts mullite. The reinforcing layer of this composition has the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com