Oxidation-preventing and noise-reducing food processor

A food processing machine and food processing technology, applied in the field of food processing machines, can solve the problems of loss of nutrients in fruits and vegetables, affecting the performance of use, and high noise, and achieve the effects of vacuum sound insulation and noise reduction, convenient assembly and maintenance, and reduced heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

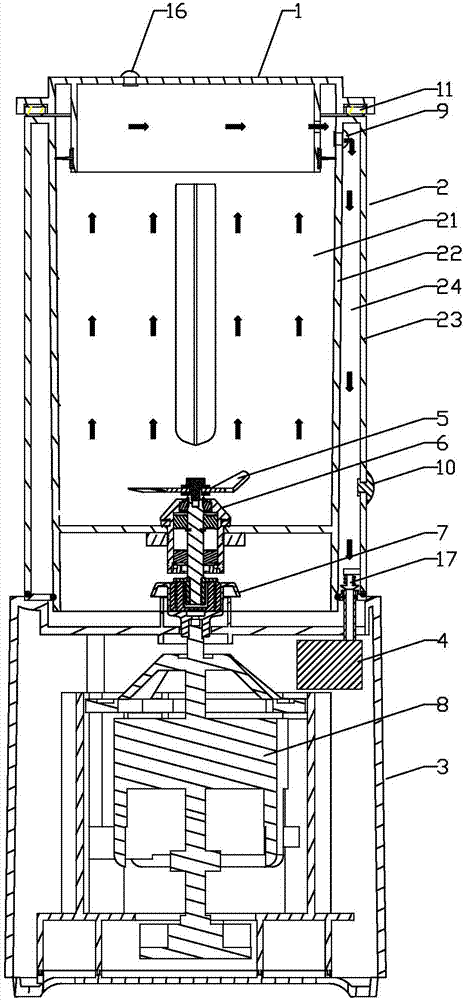

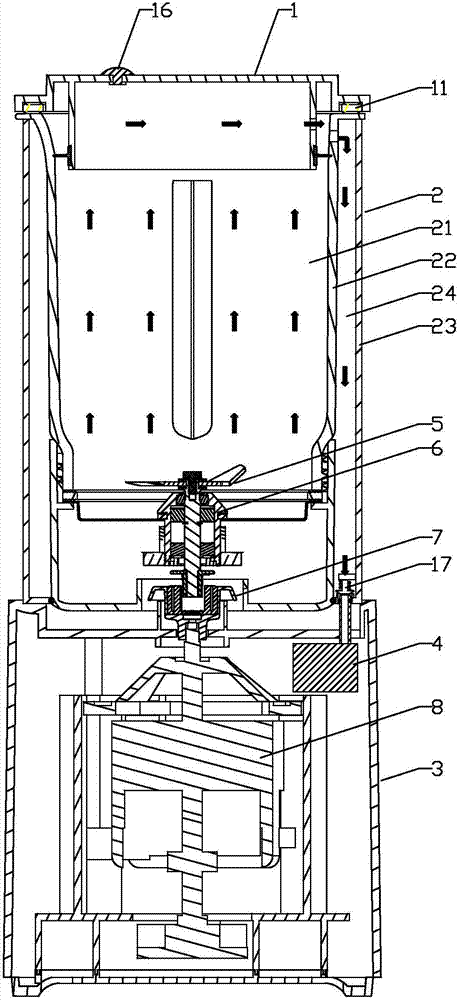

[0037] The present invention will be further described below in conjunction with the drawings, according to figure 1 with figure 2 As shown, the anti-oxidation and noise-reduction type food processor of the present invention includes a cup cover 1, a cup body 2 and a base 3. The cup cover 1 is detachably covered on the top of the cup body 2 to seal and close the inside of the cup body 2. In the food processing chamber 21, the cup body 2 is detachably assembled on the top of the base 3; the inner cavity of the base 3 is provided with a vacuum device 4, and the side wall of the cup 2 is a double-layer structure formed by an inner wall 22 and an outer wall 23 in clearance fit , The gap between the inner wall 22 and the outer wall 23 forms a closed interlayer cavity 24; the food processing cavity 21 and the interlayer cavity 24 are in communication with each other, and the suction end of the vacuum device 4 is connected to the interlayer cavity 24 and the food processing cavity 21 i...

no. 2 example

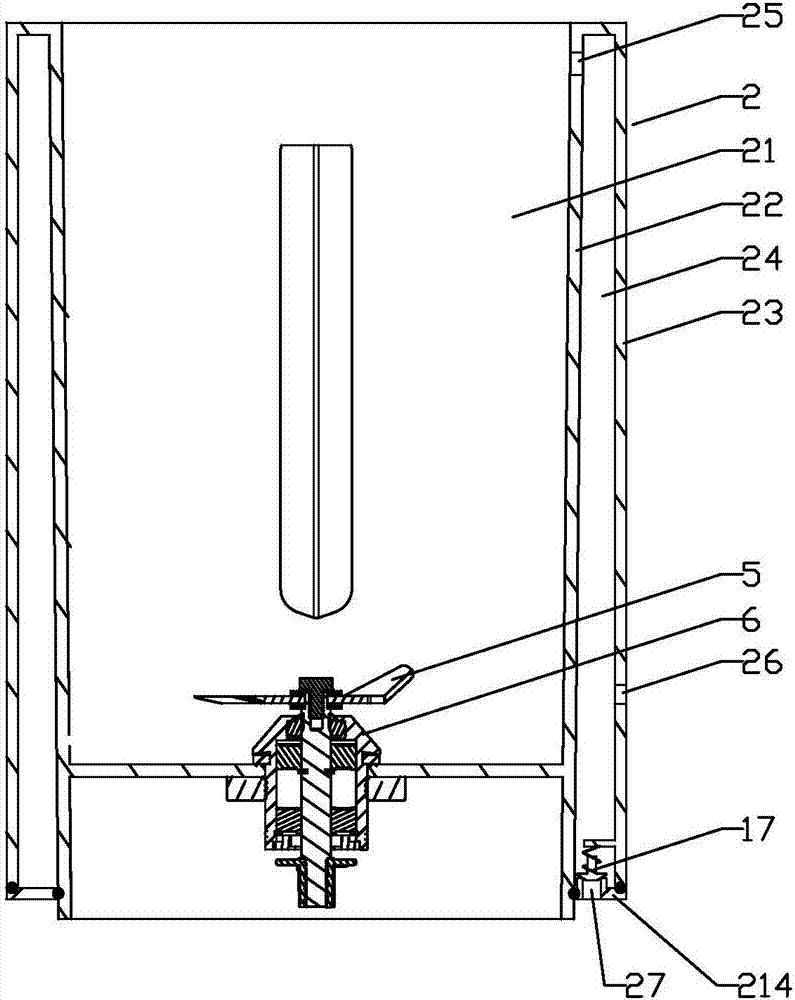

[0048] See image 3 with Figure 4 The anti-oxidation and noise-reduction type food processor is different from the first embodiment in that: the cup body 2 is a separate arrangement, which includes an inner cup 211, an outer cup 212 and a cup holder 213. The inner cup 211 and the cup holder 213 are respectively The outer cup 212 is inserted into the outer cup 212 to form a sleeve-shaped sandwich cavity 24. The inner cup 211 is assembled on the top of the cup holder 213. The food processing cavity 21 is the inner cavity of the inner cup 211. The inner wall 22 is the side wall of the inner cup 211 and the outer wall 23 It is the side wall of the outer cup 212; the inner cup 211, the outer cup 212, and the cup holder 213 are provided with a sealing member between each other, so as to seal and cooperate with each other.

[0049] Other undescribed parts are the same as in the first embodiment, and will not be described in detail here.

no. 3 example

[0051] See Figure 5 The anti-oxidation and noise-reduction food processor is different from the first embodiment in that: the outer wall 23 of the cup body 2 is provided with a vent 28 communicating with the interlayer cavity 24, and the top of the cup cover 1 is provided with a communicating food processing cavity 24 The second air extraction hole 101, the air hole 28 and the second air extraction hole 101 are communicated with each other through a vacuum tube body 12, so that the food processing cavity 21 and the interlayer cavity 24 are communicated with each other; to prevent food from entering the second air extraction hole 101 by mistake, A filter element 13 is provided at the second suction hole 101.

[0052] Other undescribed parts are the same as in the first embodiment, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com