Bridge rib hoisting and supporting rack integral construction method and device

A technology for supporting brackets and construction methods, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as insufficient lifting capacity, long construction time, and inflexible floating cranes, and reduce equipment and capital investment. , The cycle of assembly is shortened, and the lifting method is flexible.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

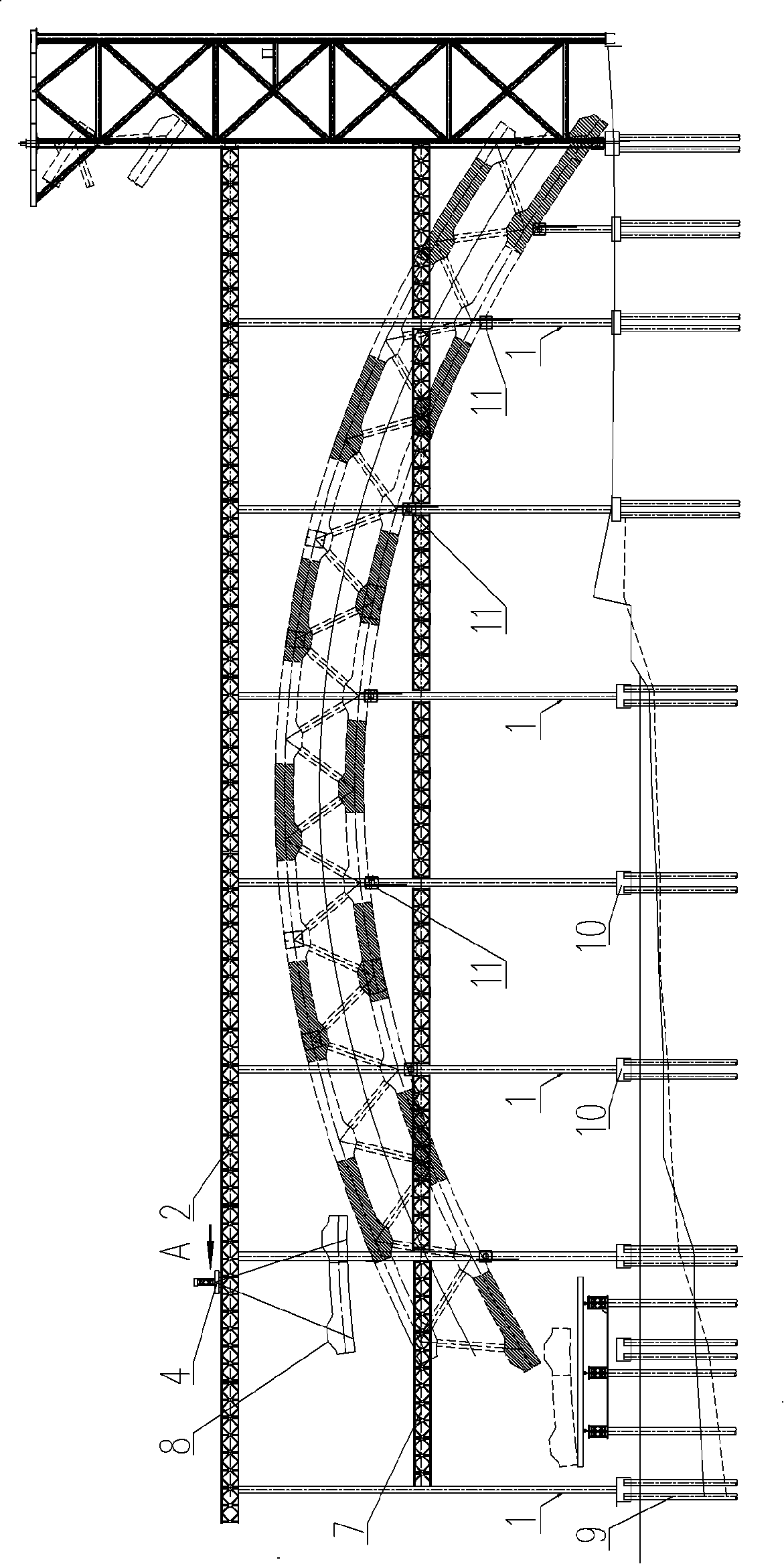

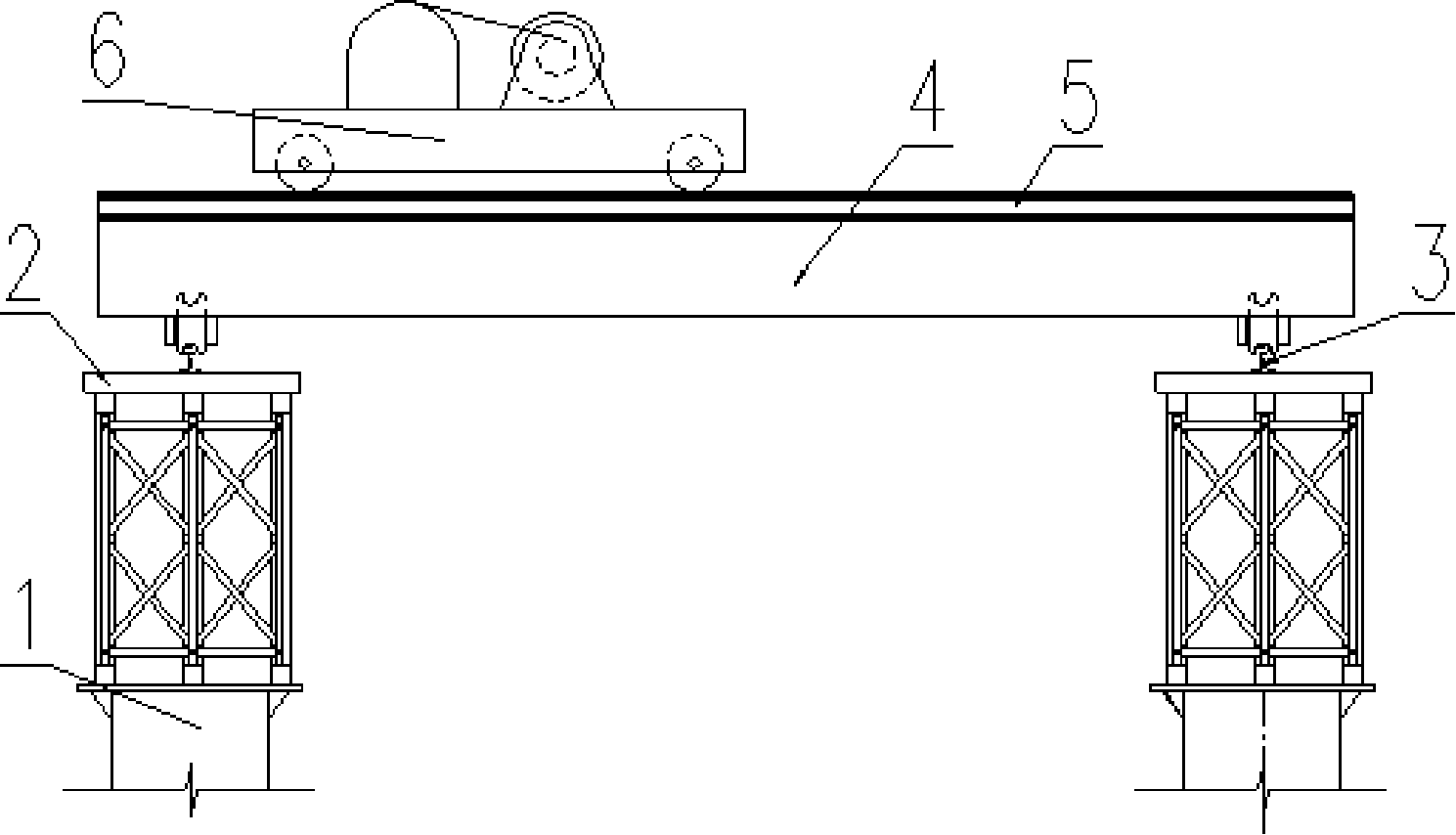

[0017] Embodiments of the present invention: as figure 1 As shown, a part of the construction site of the bridge arch rib is on land, and a part is on the water, and a column 1 is set within the arch rib assembly range. See figure 2 , the columns 1 can be arranged in 2 rows, including the entire assembly range, the number and spacing of the columns 1 can be determined according to the design, the supporting corbels 11 are installed on the corresponding elevation of the columns 1, and the arch ribs 8 of each section are hoisted and located on the corbels. On the leg 11; install the hoisting beam 2 on the column 1, the hoisting beam 2 is provided with a longitudinal moving track 3, the crane 4 is installed on the longitudinal moving track 3, and the crane 4 is provided with a traversing track 5, the traversing track 5 is provided with a hoist 6 that moves laterally, and the arch rib 8 is hoisted to each assembly position by the hoist 6 . In order to be more stable, support tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com