Axial-flow compressor unit body component assembling device and method

An assembly device and compressor technology, which can be applied to hand-held tools, manufacturing tools, etc., can solve problems such as affecting the engine assembly cycle, and achieve the effect of reducing labor intensity of workers and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

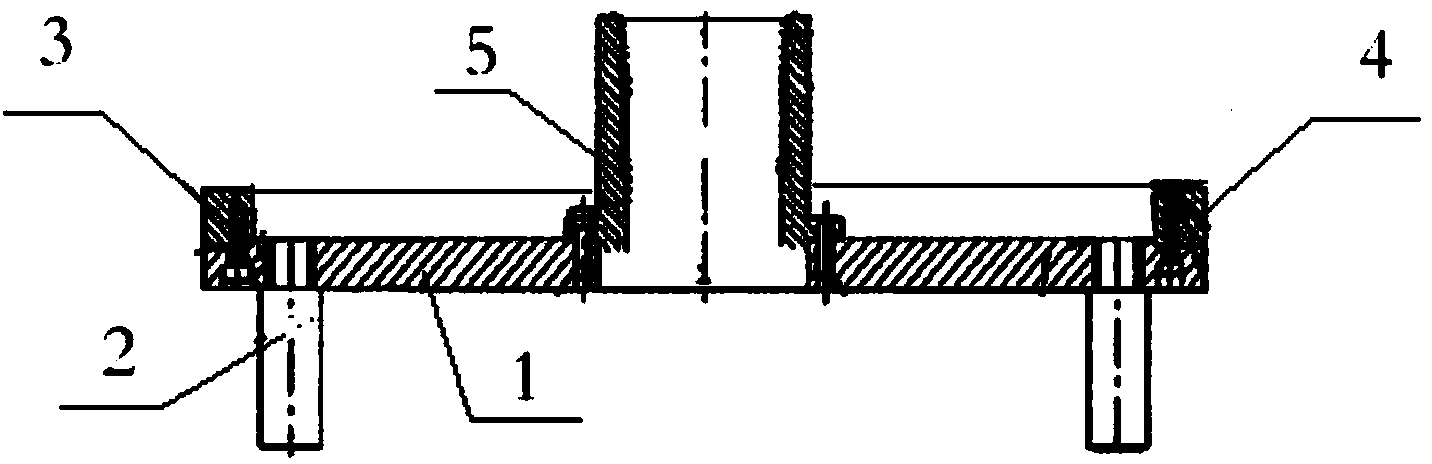

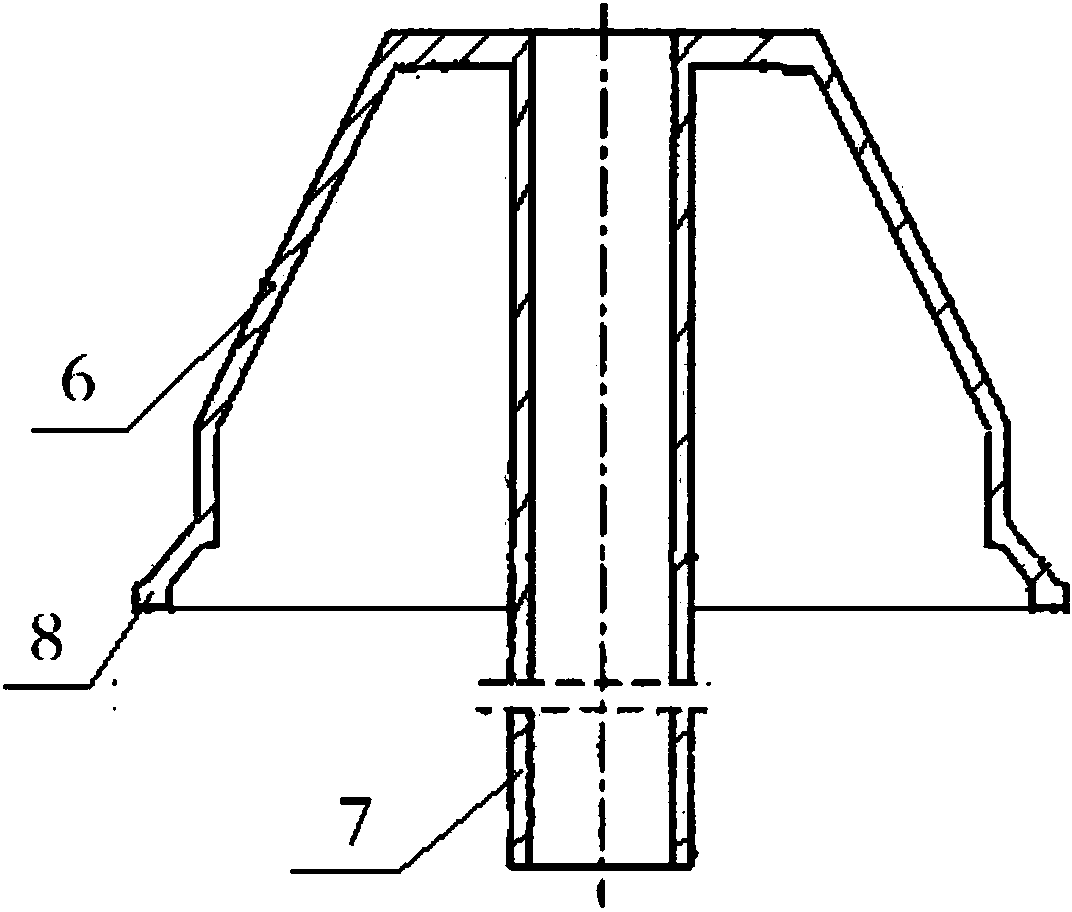

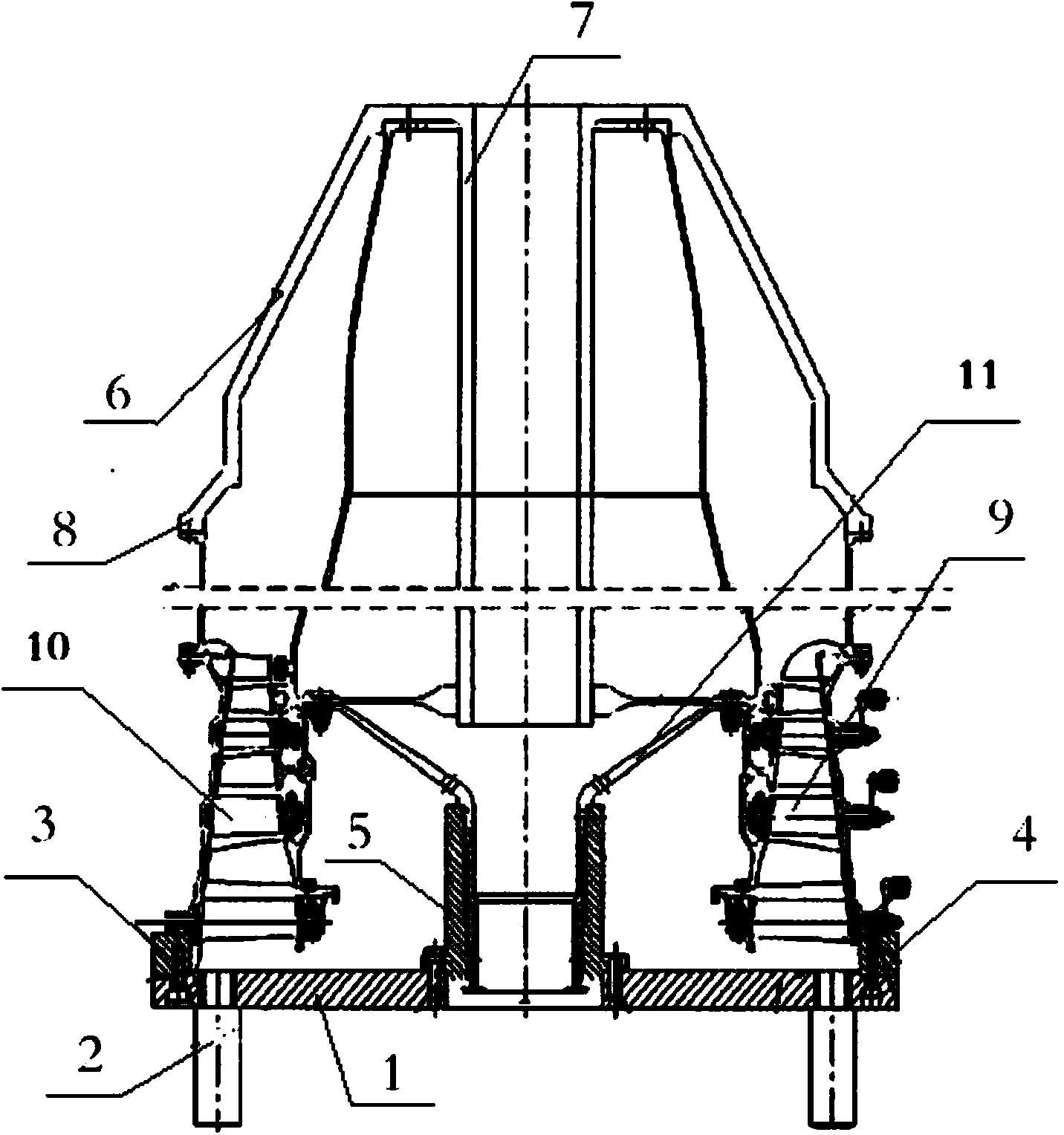

[0026] Such as figure 1 , 2 As shown, an axial-flow compressor unit assembly assembly device includes a base and a centering mechanism. The base includes a disc 1, a foot 2, a positioning half ring 1 3, a positioning half ring 2 4 and a positioning sleeve 5, Described supporting foot 2 is arranged on described disc 1 below, and described positioning semi-ring one 3, positioning semi-ring two 4 and positioning sleeve 5 are arranged on described disc 1; Described centering mechanism comprises hollow shaft 7 and positioning Cover 6, the hollow shaft 7 is arranged at the center of the positioning cover 6, and the outer edge of the positioning cover 6 is provided with a positioning edge 8. Positioning pins are arranged between the first positioning half ring 3 and the second positioning half ring 4 and the disc 1 . A positioning shaft is provided between the positioning sleeve 5 and the disc 1 for fixing the relative position between the positioning sleeve 5 and the disc 1 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com