Refrigerated truck bed

A car box and rear frame technology, applied in the field of connection structure of side panels and rear frames, can solve the problems of low efficiency, long assembly cycle of side panels and rear frames, inconvenient disassembly, etc. The effect of shortening the assembly cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

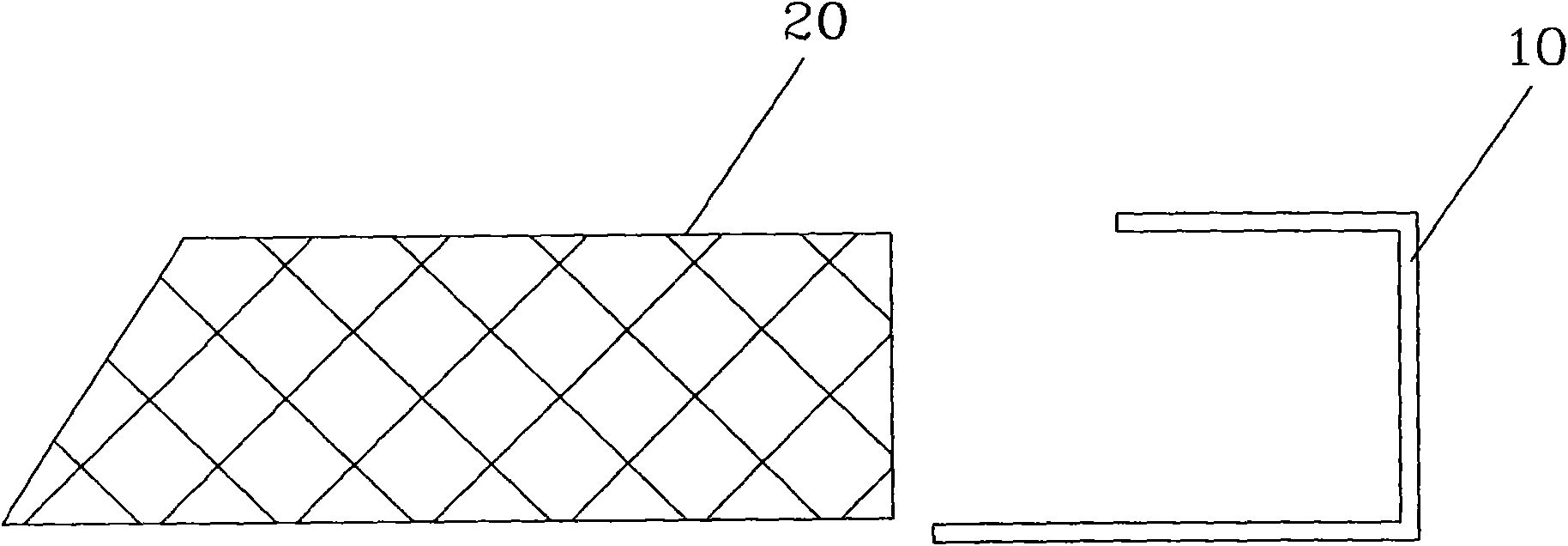

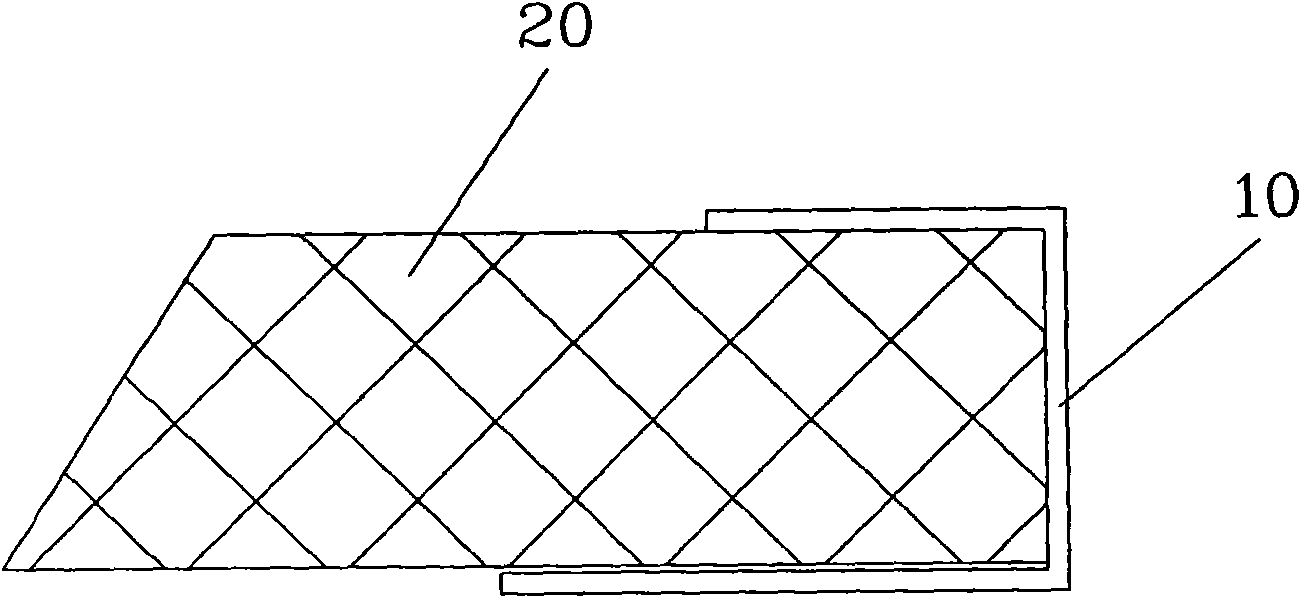

[0018] The refrigerated vehicle box is a cuboid box body, which is composed of a frame, a top plate installed on the frame, a floor, two side panels, a front panel and a rear panel. Wherein the frame is provided with a rear frame for installing side panels.

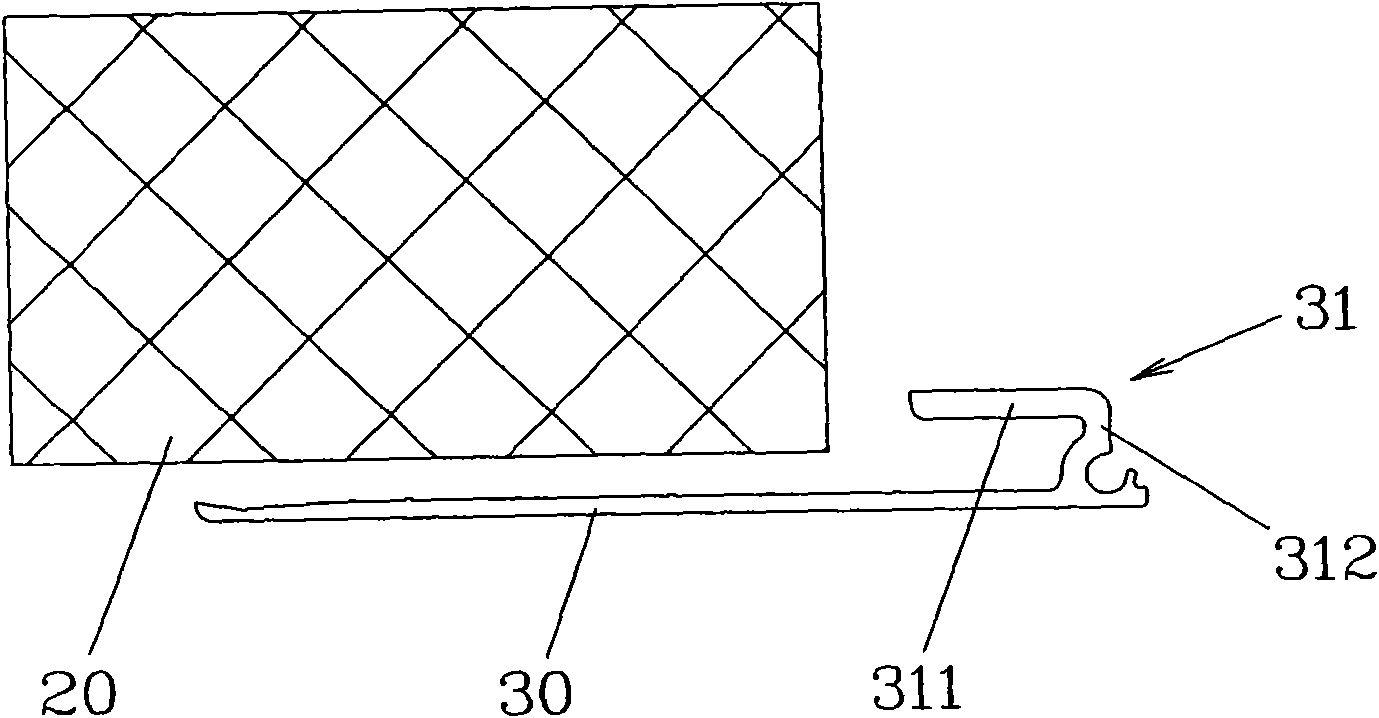

[0019] Such as image 3 , Figure 4 with Figure 5 As shown, in the refrigerated car box of the present invention: the side panel 20 is installed in the rear frame 10 of the frame by the aluminum profile 30 and the rear side corner seal 40 . in

[0020] The side panels are the same as those in the prior art, and will not be repeated here.

[0021] The cross-section of the rear frame 10 is in a right-angle shape, and is composed of a first right-angle side 101 and a second right-angle side 102 perpendicular to each other. A corner seal connecting portion 103 extends from the end of the second right-angled side 102 of the rear frame 10 , and a rear frame connecting portion 11 extends from the end of the first right-an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com