Packing-off piece installation device of turbine stator blades and use method of packing-off piece installation device

A turbine stator and installation device technology, which is applied to stators, leakage prevention, engine components, etc., can solve the problems that the interference fit between the positioning pin and the turbine casing is difficult to disassemble, and the sealing sheet is difficult to install, etc., so as to shorten the assembly cycle and facilitate the installation. , the effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

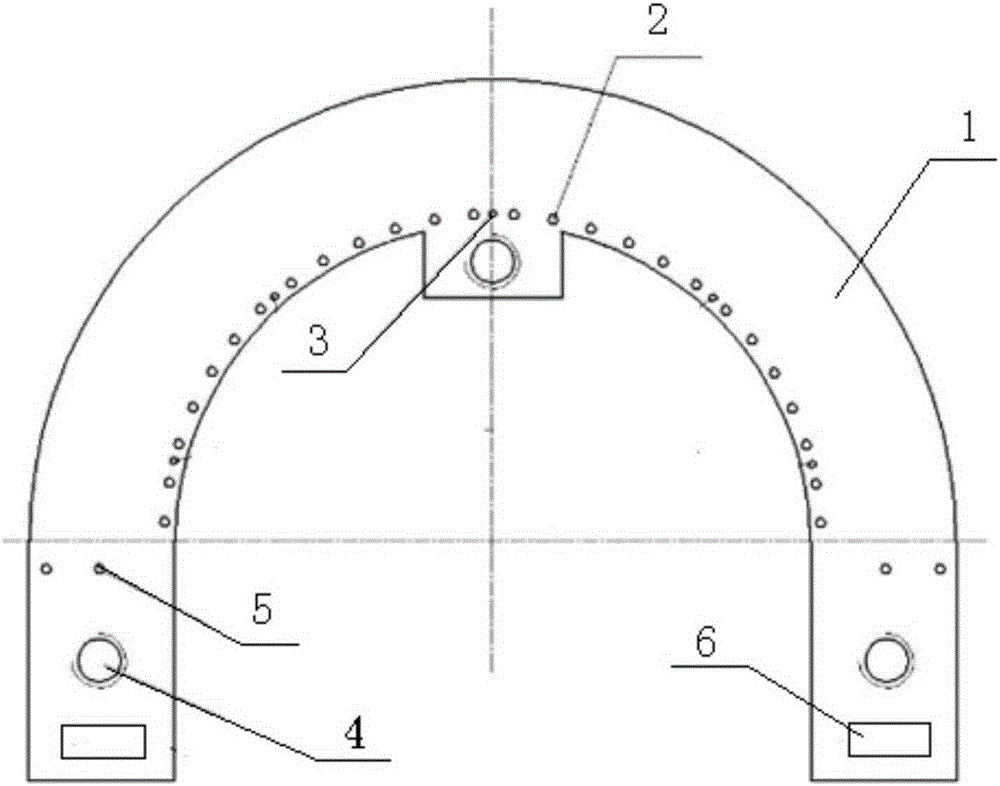

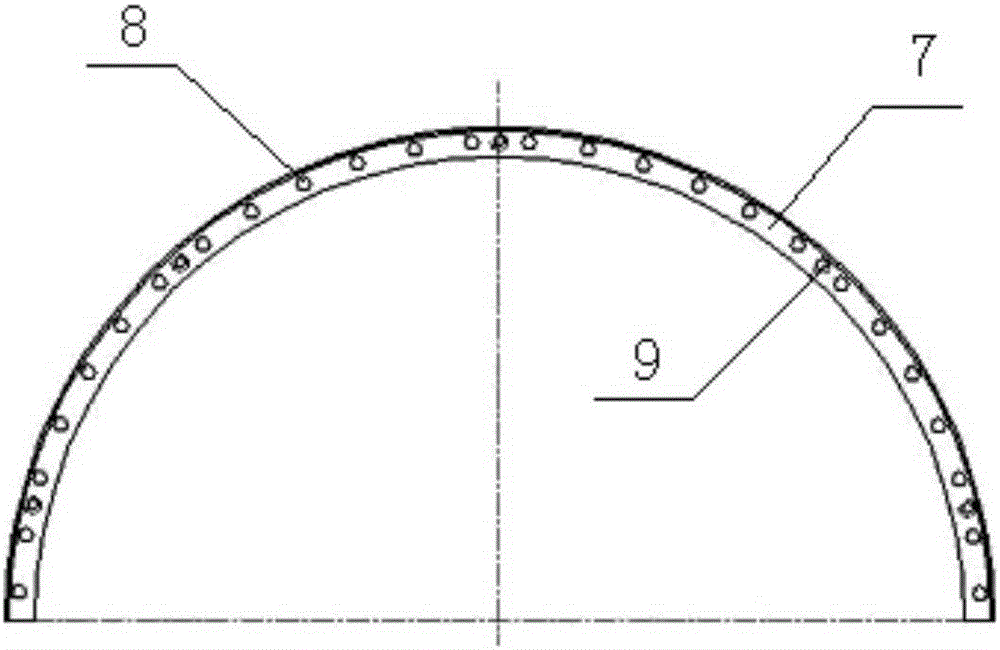

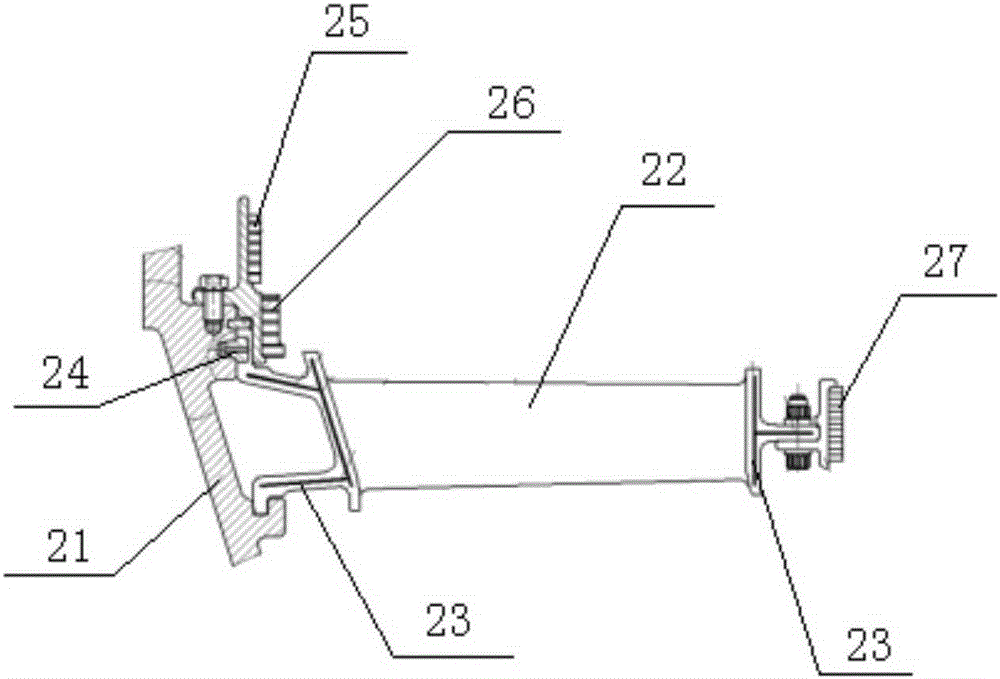

[0026] Such as Figure 1~6 As shown, a turbine stator blade sealing piece installation device includes a mounting plate 1, a mounting edge 7, a backing plate 11, a screw 1, a counterweight 6, a limit block 10, a screw 2, a fixing bolt 12 and a nut. The mounting plate 1 is a semicircular plate with two end plates and an auxiliary plate at the arc top, the semicircular plate is provided with a mounting hole 2 and a round hole 3, and the distance between the mounting hole 2 and the working state The distance between the end holes of the two turbine stator blades 22 is the same, the end plate and the auxiliary plate are provided with hoisting holes 4; the counterweight 6 is fixedly installed on the end plate, and the limit block 10 Installed on the end plate by screw 2; the mounting edge 7 is semicircular, and mounting hole 2 8 and screw hole 9 are set on it; screw 1 penetrates the round hole 3 and is screwed into the screw hole 9 to fix the mounting plate 1 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com