Heavy combustion engine assembling method for assembling rotor and front and rear supports in combining manner

A technology of front support and rear support, which is applied to gas turbine devices, mechanical equipment, jet propulsion devices, etc., can solve the problem that the rotor cannot be installed horizontally with the stator components, and achieve the effect of shortening the assembly cycle and convenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

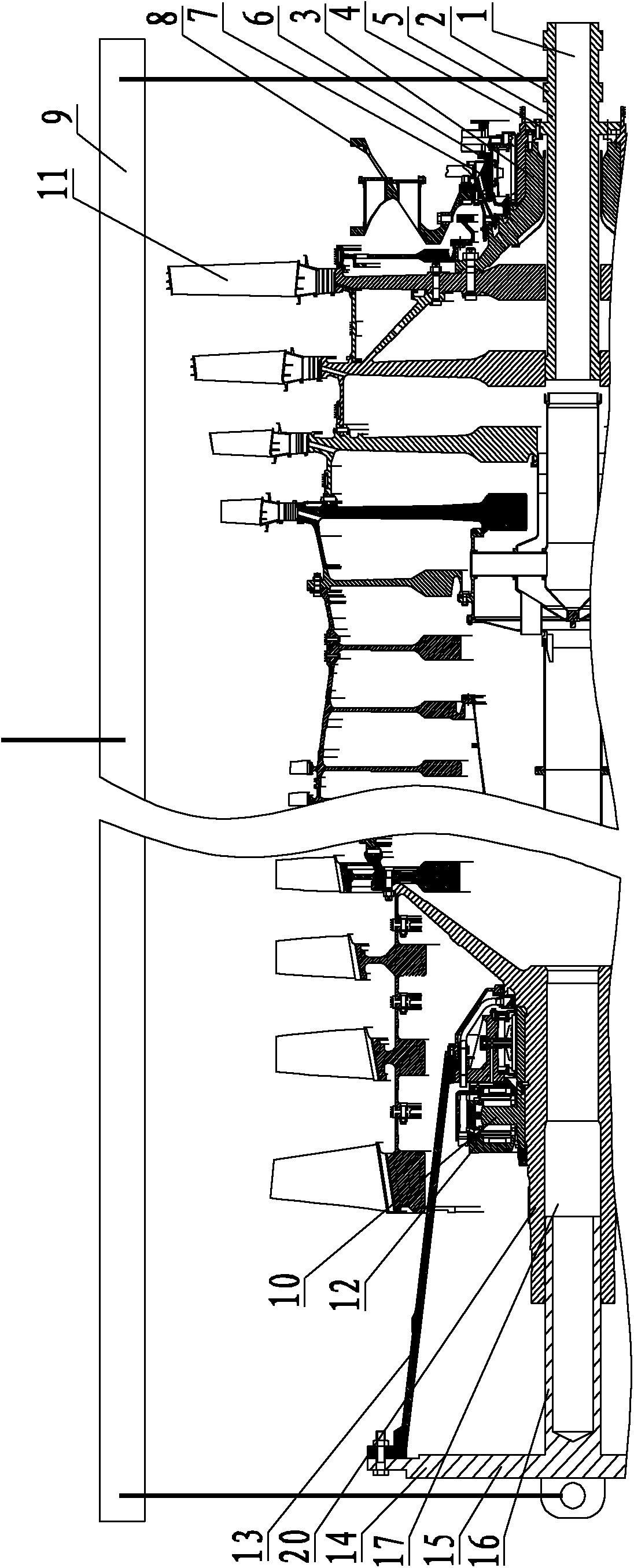

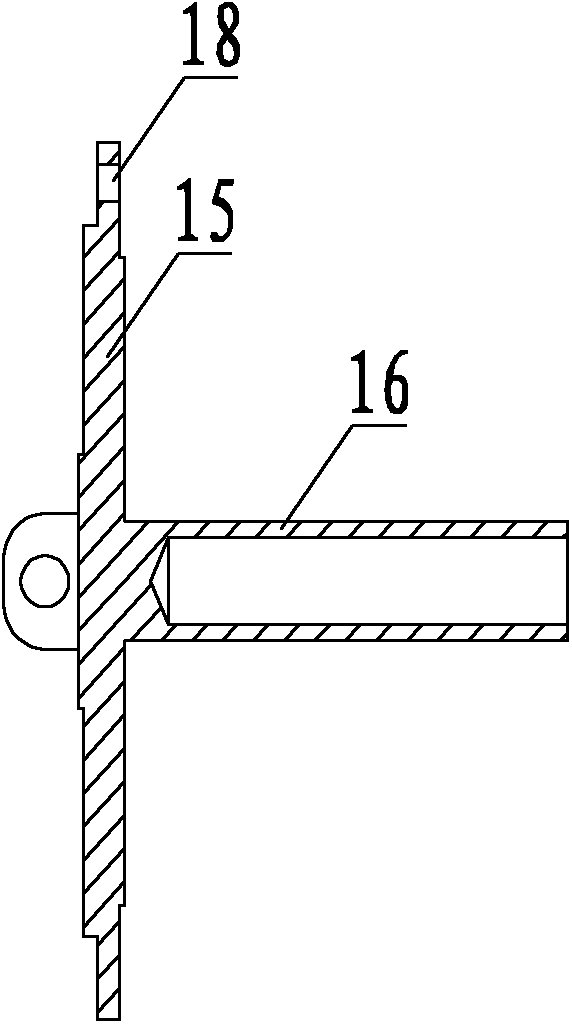

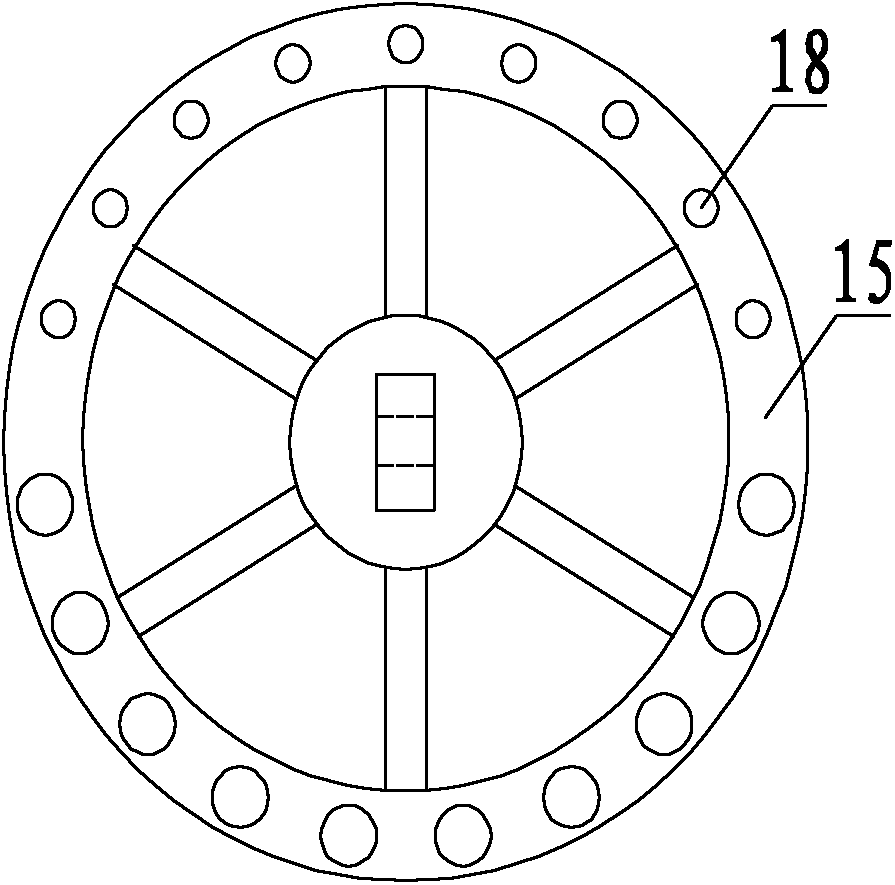

[0025] Such as Figure 1~5 As shown, a method for assembling a heavy-duty gas turbine in which the rotor and the front and rear supports are assembled, includes the following steps:

[0026] Step 1: Assemble the front bearing assembly 12 and the front support cylinder 13 vertically to form the front support 10 through bolts; Assemble the rear bearing assembly 7 and the rear support cylinder 8 to form the rear support 6 through bolts;

[0027] Step 2: Place the gas turbine rotor 11 horizontally on a support seat fixed to the ground. The V-shaped front and rear supports of the support seat are respectively between the first and second stages of the rotor compressor, and the third and fourth stages of the turbine. The drum surface between the stages is in contact with the rubber pad in the middle, and the pin on the support seat is inserted into the radial exhaust hole of the gas turbine rotor 11 to achieve axial positioning;

[0028] Step 3: Mount the front support 10 and the rear sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com