A six-wheel drive dumper assembling method

An assembly method and dump truck technology, applied in the direction of motor vehicles, vehicle parts, transportation and packaging, can solve the problems of difficult assembly, difficult pipeline layout, long cycle, etc., and achieve the effect of reducing assembly cycle and facilitating troubleshooting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

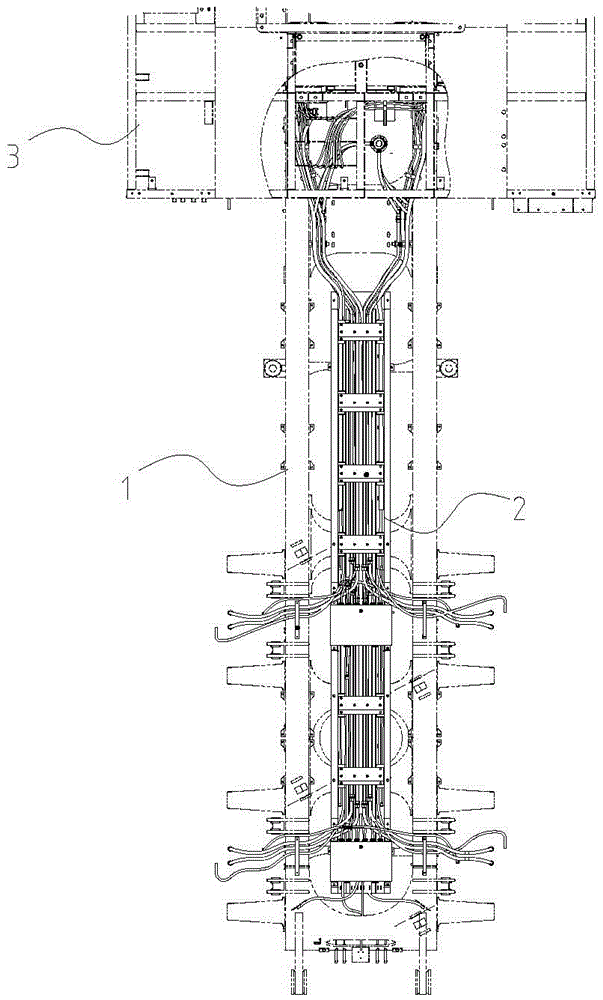

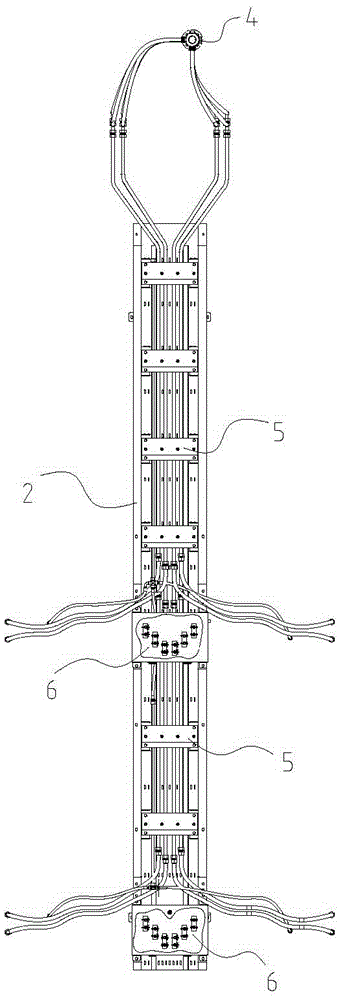

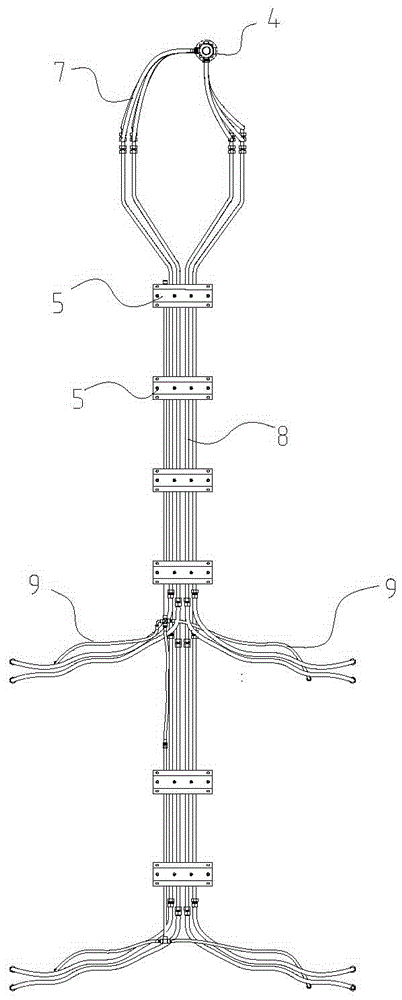

[0029] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0030] A method for assembling a six-wheel drive dump truck, comprising the following steps:

[0031] Pre-lay the pipeline on the walking platform module 3:

[0032] (1) According to the cab, low-voltage electrical cabinet, converter, braking resistor and front axle lighting, set the direction of the wire slot at the position of the walking platform; in the pre-wiring of the wire slot of the walking platform, the wire slot is bent with a 3mm aluminum plate, and the board M6 bolt holes are opened on the top and installed on the bottom beam of the walking platform. The wire slot is divided into two sections.

[0033] (2) When the trunking is separated from the walking platform, cables are pre-distributed in the trunking;

[0034] (3) After the pre-wiring is completed, install the trunking on the bottom beam of the walking platform;

[0035] (4) The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com