Eccentric half-ball valve

A hemispherical valve, eccentric technology, applied in the direction of the valve device, the cock including the cut-off device, engine components, etc., can solve the problems such as troublesome production and use of customers, achieve the effect of convenient and fast maintenance, shorten the assembly cycle, and reduce technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

[0019] Such as figure 1 , figure 2 As shown, the sealing structure of the eccentric hemispherical valve in the prior art has been described in the background art, and will not be repeated here.

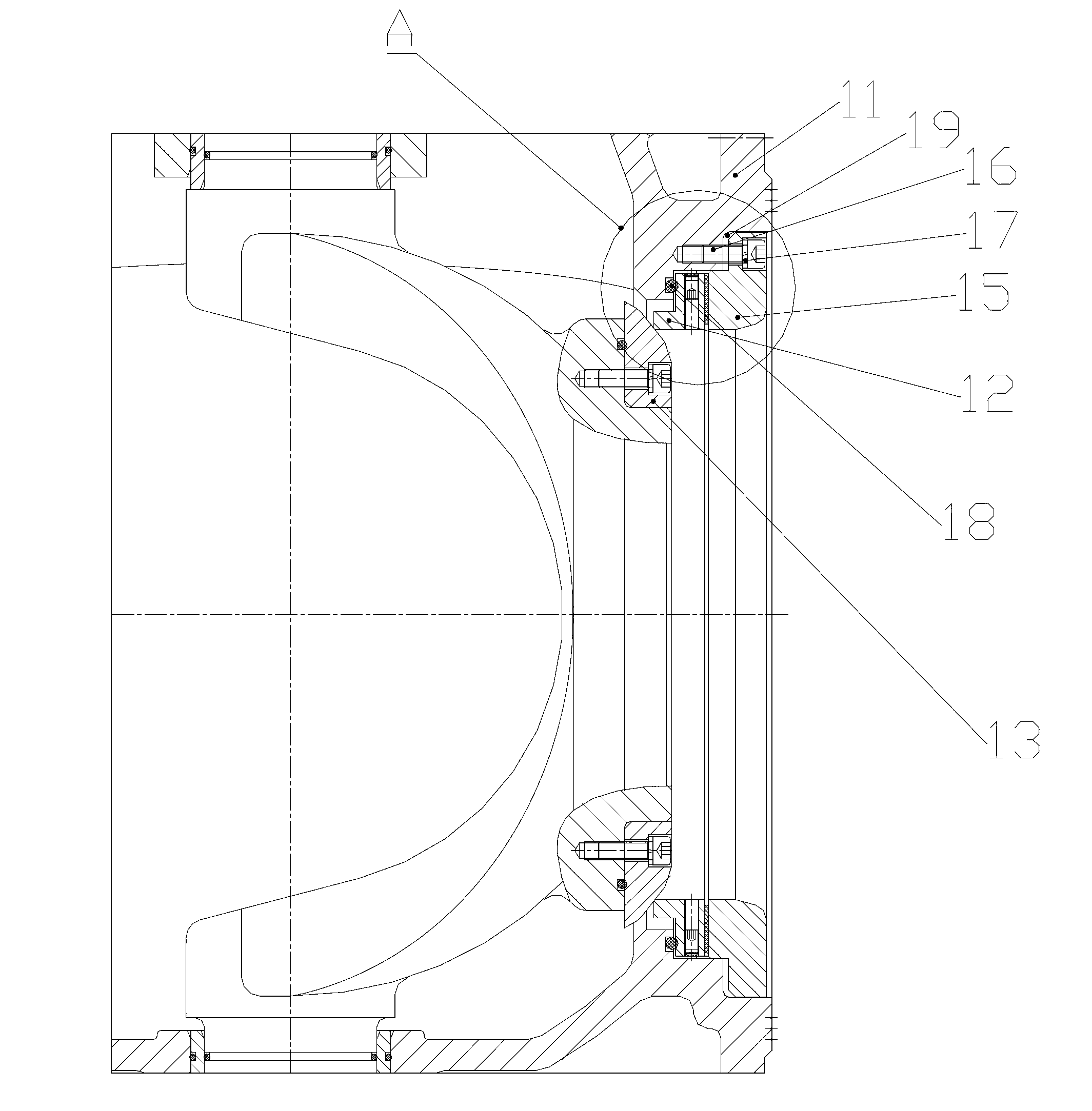

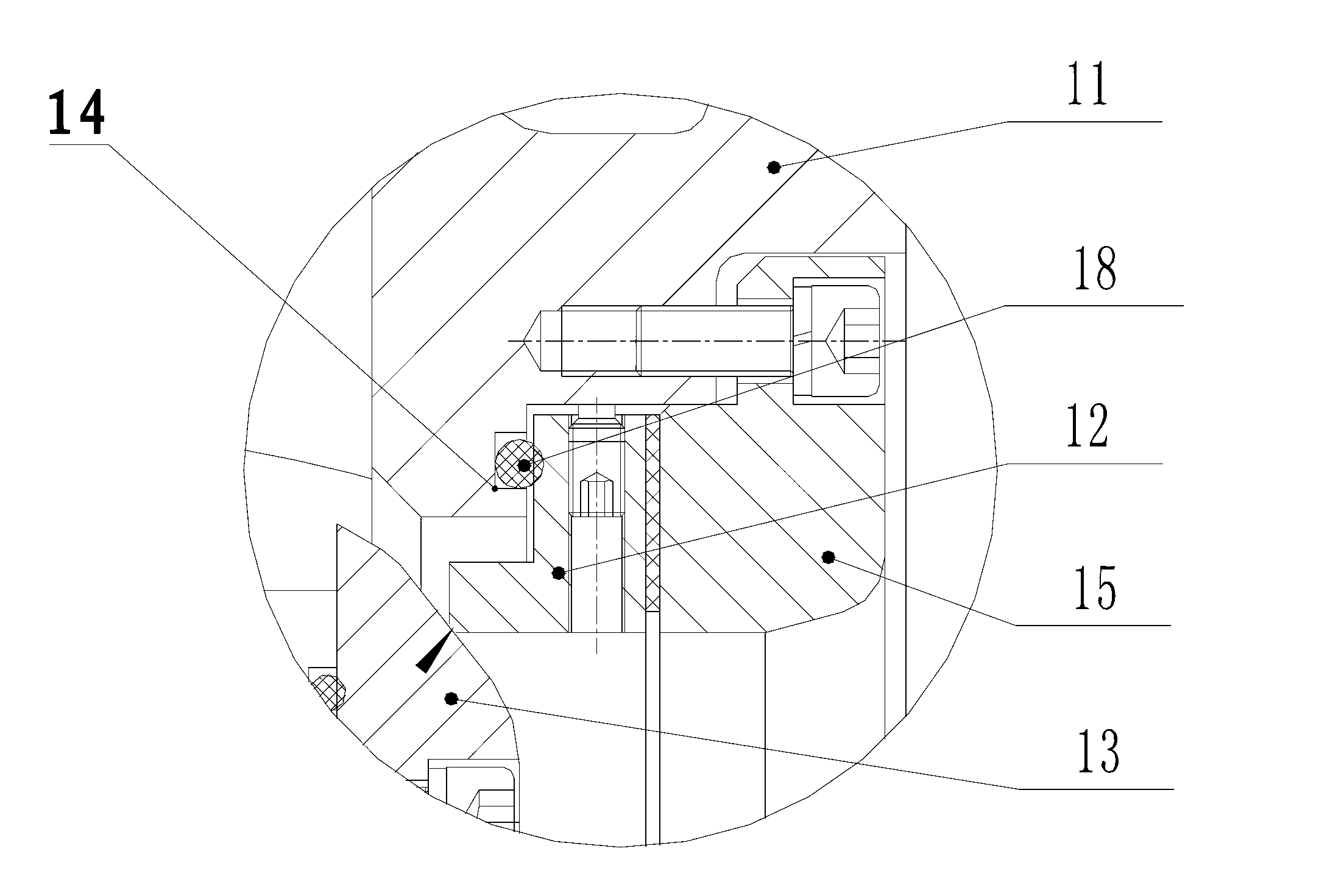

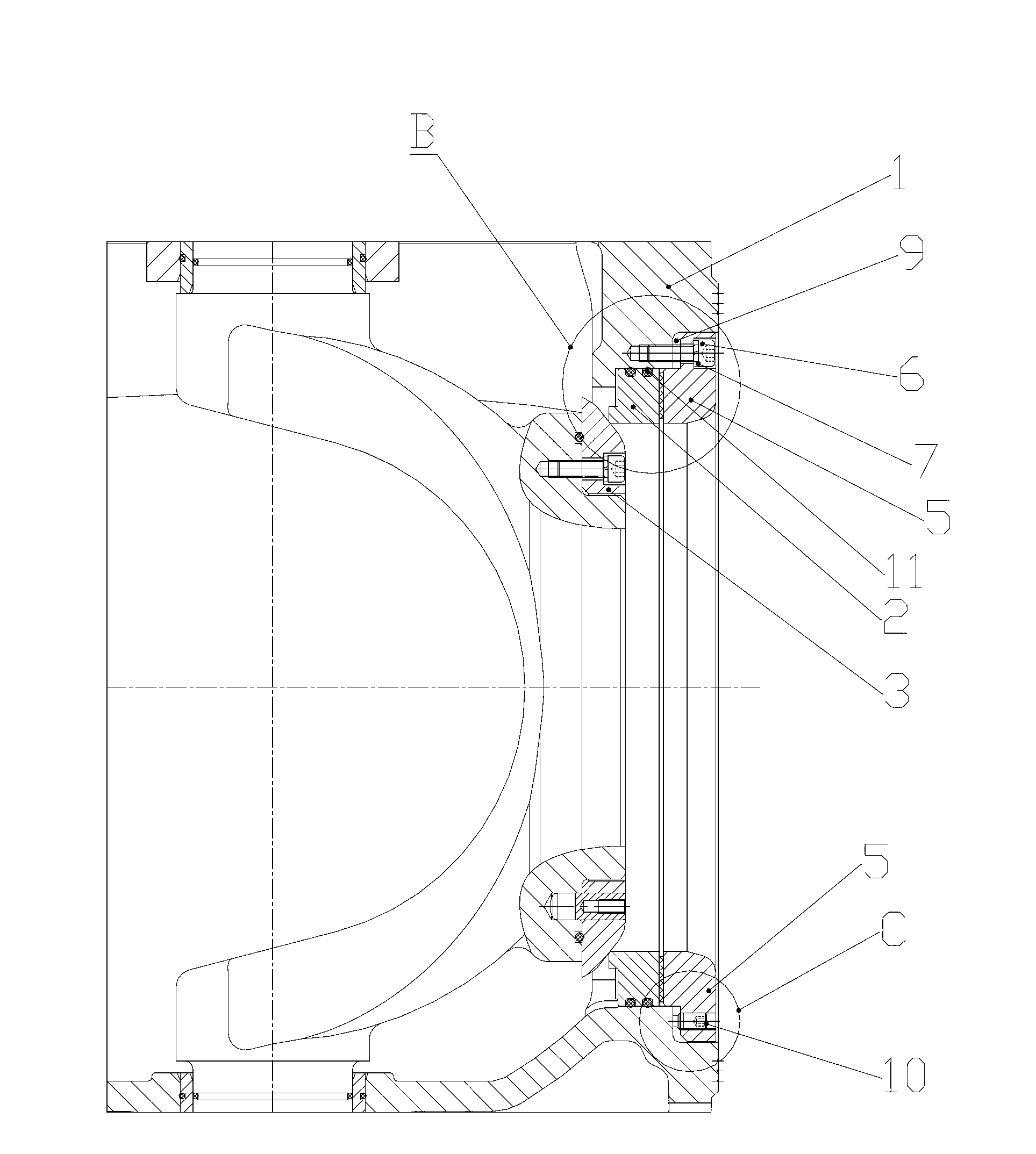

[0020] Such as image 3 , Figure 4 As shown, an eccentric hemispherical valve, which includes a valve body 1, a valve seat 2 and a spherical crown 3 that cooperate with each other are provided in the valve body 1, and the radial sealing cylindrical surface of the valve seat 2 that is mutually sealed with the valve body 1 One or more than one ring groove 4 is provided, and a sealing ring 11 is set inside the ring groove 4 . This is a radial sealing structure. In this sealing structure, the compression of the sealing ring 11 depends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com