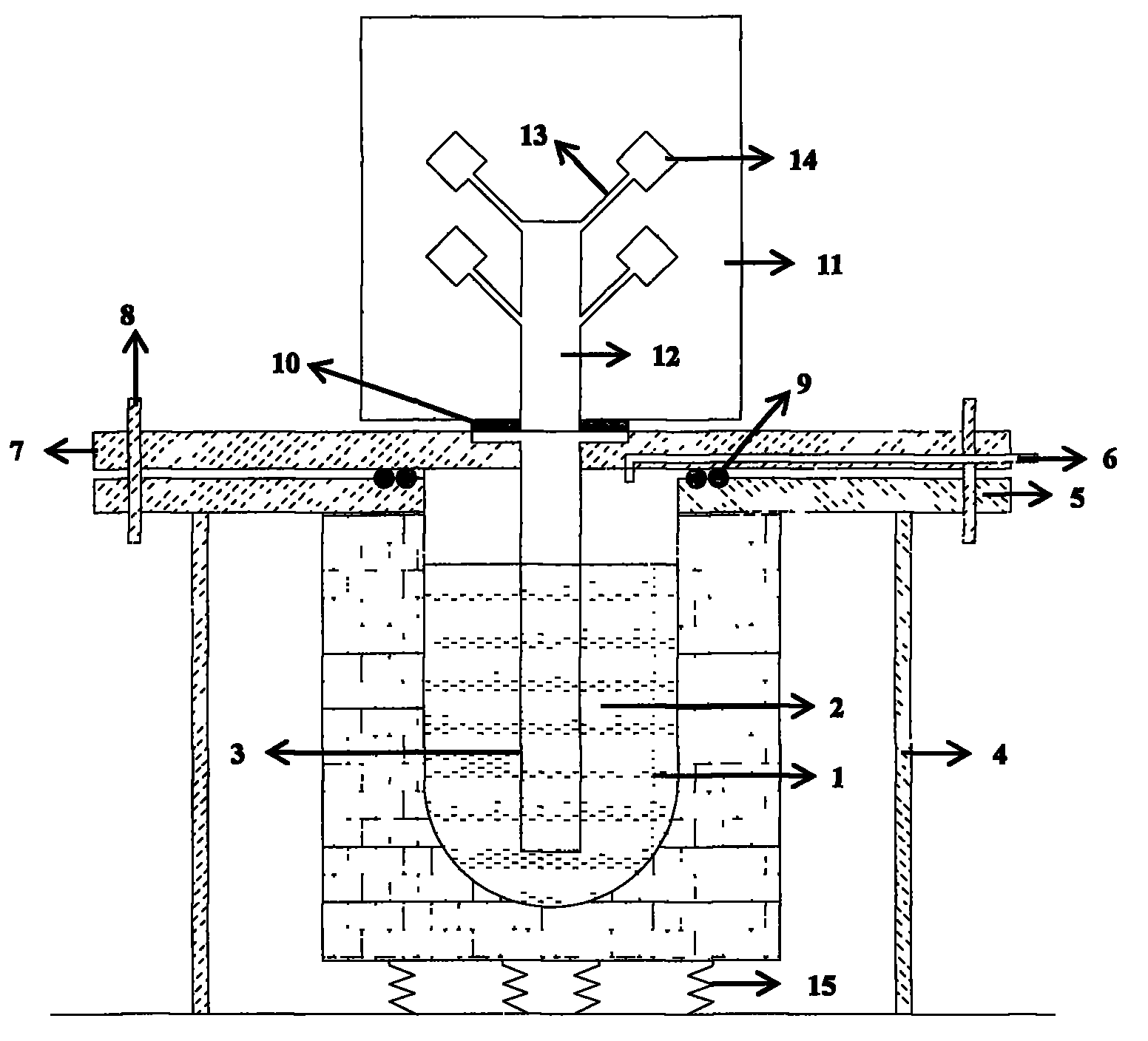

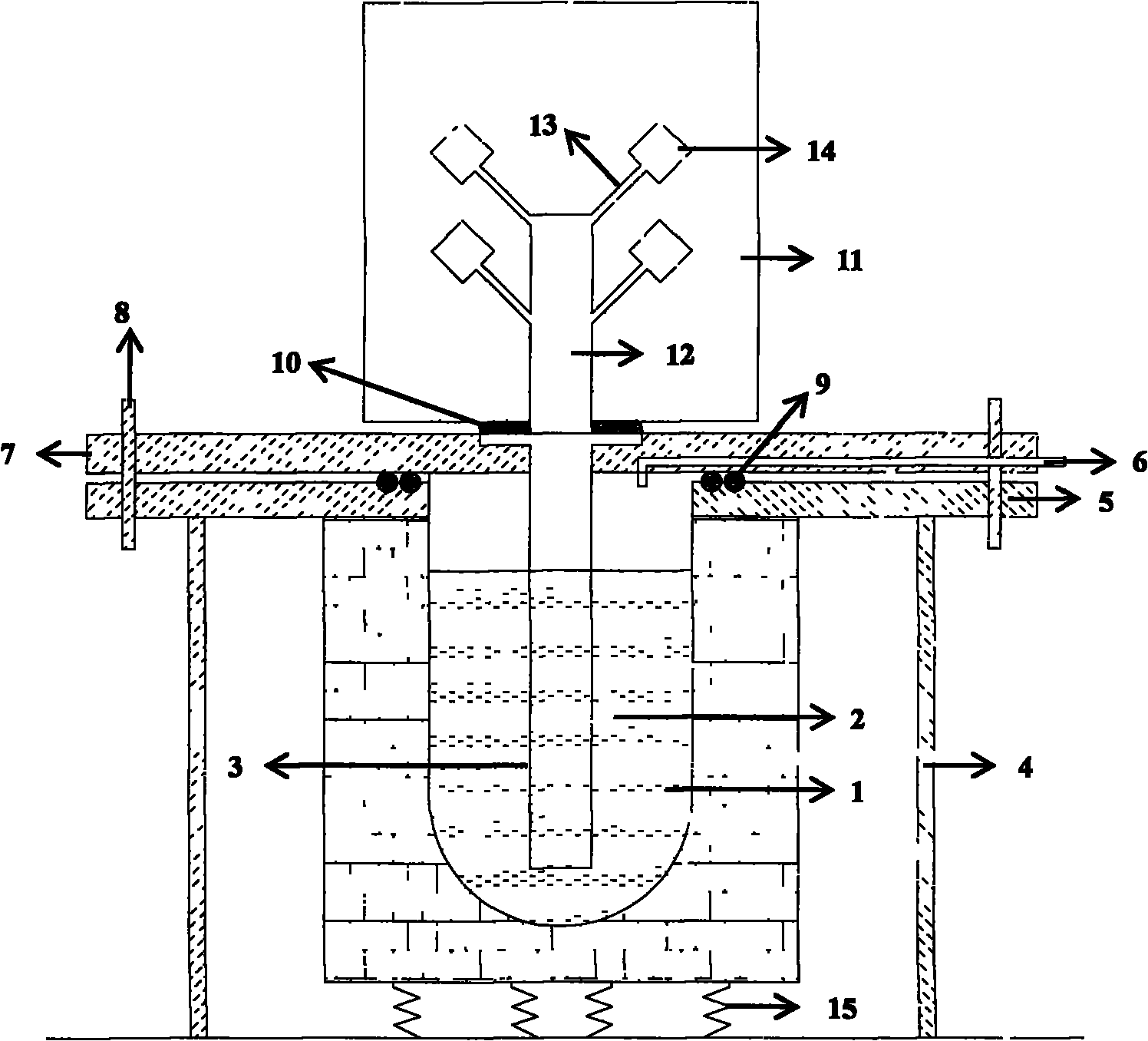

Sealing method used for low-pressure casting

A technology of low pressure casting and sealing cover plate, applied in the field of metal materials or metallurgy, it can solve the problems of uneven force on fastening bolts, unlocked force on bolts, affecting the sealing effect, etc., so as to shorten the assembly cycle and reduce the working strength. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In the production practice of sand mold low-pressure casting of aluminum alloy large shells (several hundred kilograms), when the above-mentioned sealing method is used for production, no air leakage is found in the low-pressure casting process, which shows that this method has good sealing performance.

[0010] In the production practice of sand mold low-pressure casting of magnesium alloy small castings (tens of kilograms), when the above-mentioned sealing method is used for production, an additional metal mold is placed above the mold to increase the weight of the mold, and no gas leakage occurs during the entire process of low-pressure casting This phenomenon shows that this method has excellent sealing performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com