Flexible wallboard assembling tool

A technology of assembly tooling and flexible wall panels, which is applied in aircraft assembly and other directions, can solve problems such as inability to respond quickly to panels, backward aircraft assembly technology, and increased aircraft manufacturing costs, achieving shortened production preparation cycles, high positioning accuracy, and easy maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

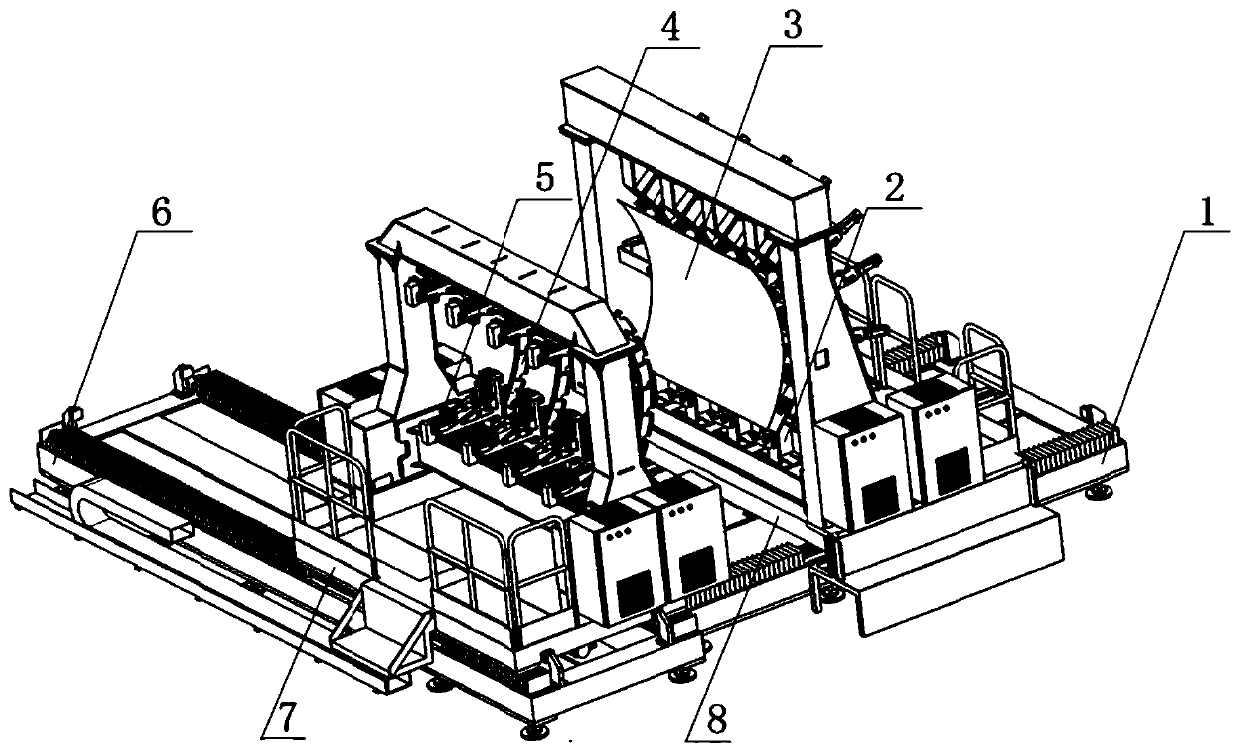

[0048] See figure 1 The flexible wall panel assembly tool of this embodiment includes a base, and the base is provided with a processing station, an assembly station, and a hole-making station. The base includes a first fixed base 1 and a second fixed base 6 that are perpendicular to each other. The first fixed base 1 is equipped with a skin adsorption unit 2 through an X-direction sliding table 8, and the second fixed base 6 is installed with a Y-direction sliding platform 7. Wall panel frame positioning assembly 5. The skin 3 is fixed by the skin adsorption unit 2, and the wall plate frame 4 is fixed by the wall plate frame positioning assembly 5, and the assembly process is performed at the assembly station.

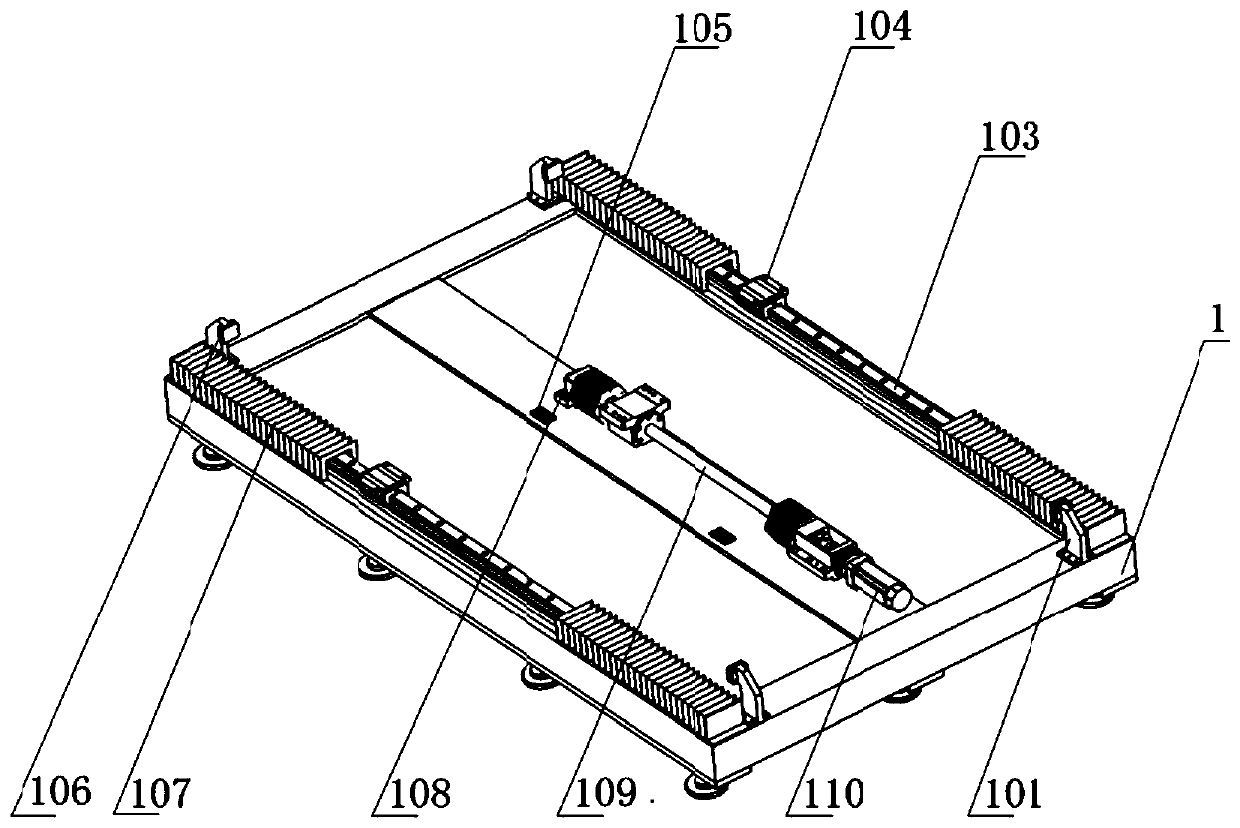

[0049] See figure 2 , The first fixed base 1 is provided with a limit block 101, a limit block 106, an X-direction guide rail 103, a slider 104, a limit switch 105, a guide rail protective cover 107, a screw fixing seat 108, an X-direction screw 109 and a servo Motor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com