Steam turbine blade-cascade assembling frock

A technology for assembling tooling and steam turbines, applied in auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problems of increased cost of steam turbines, low work efficiency, lack of versatility, etc., to save materials, improve work efficiency, and reduce tooling Quantity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

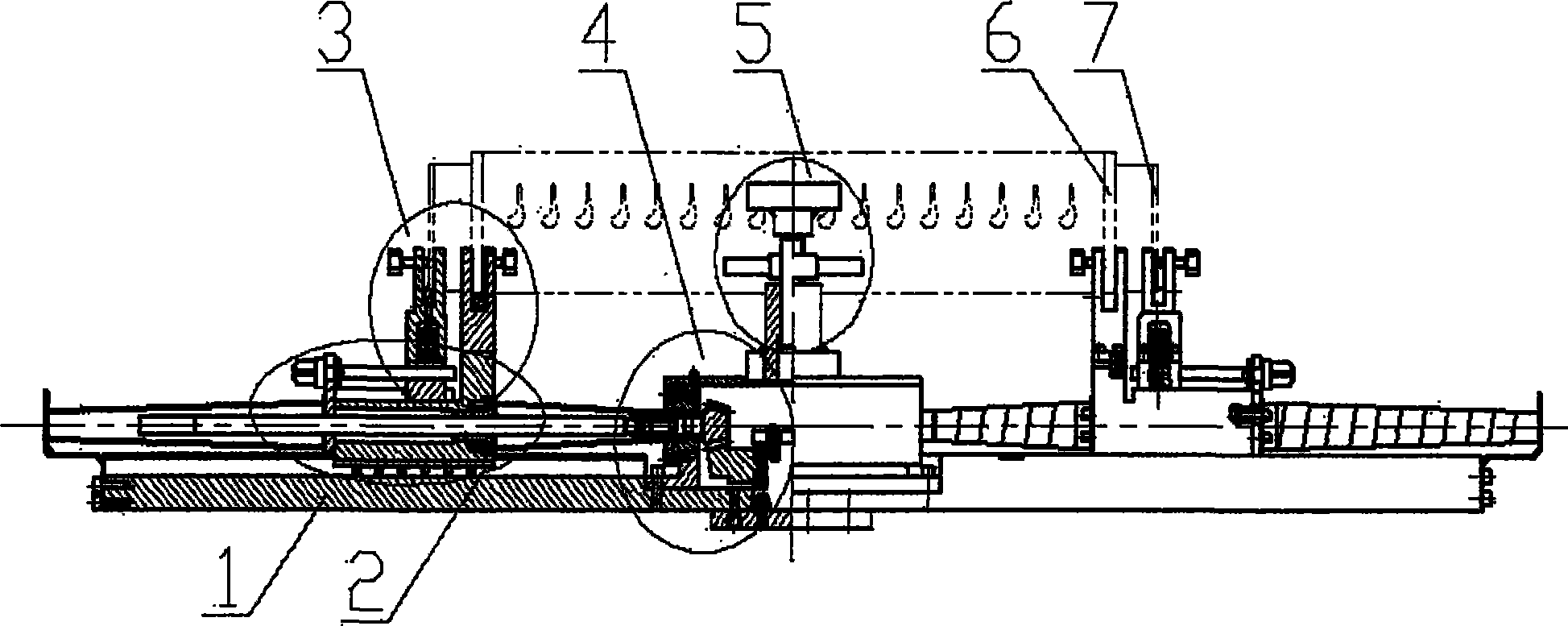

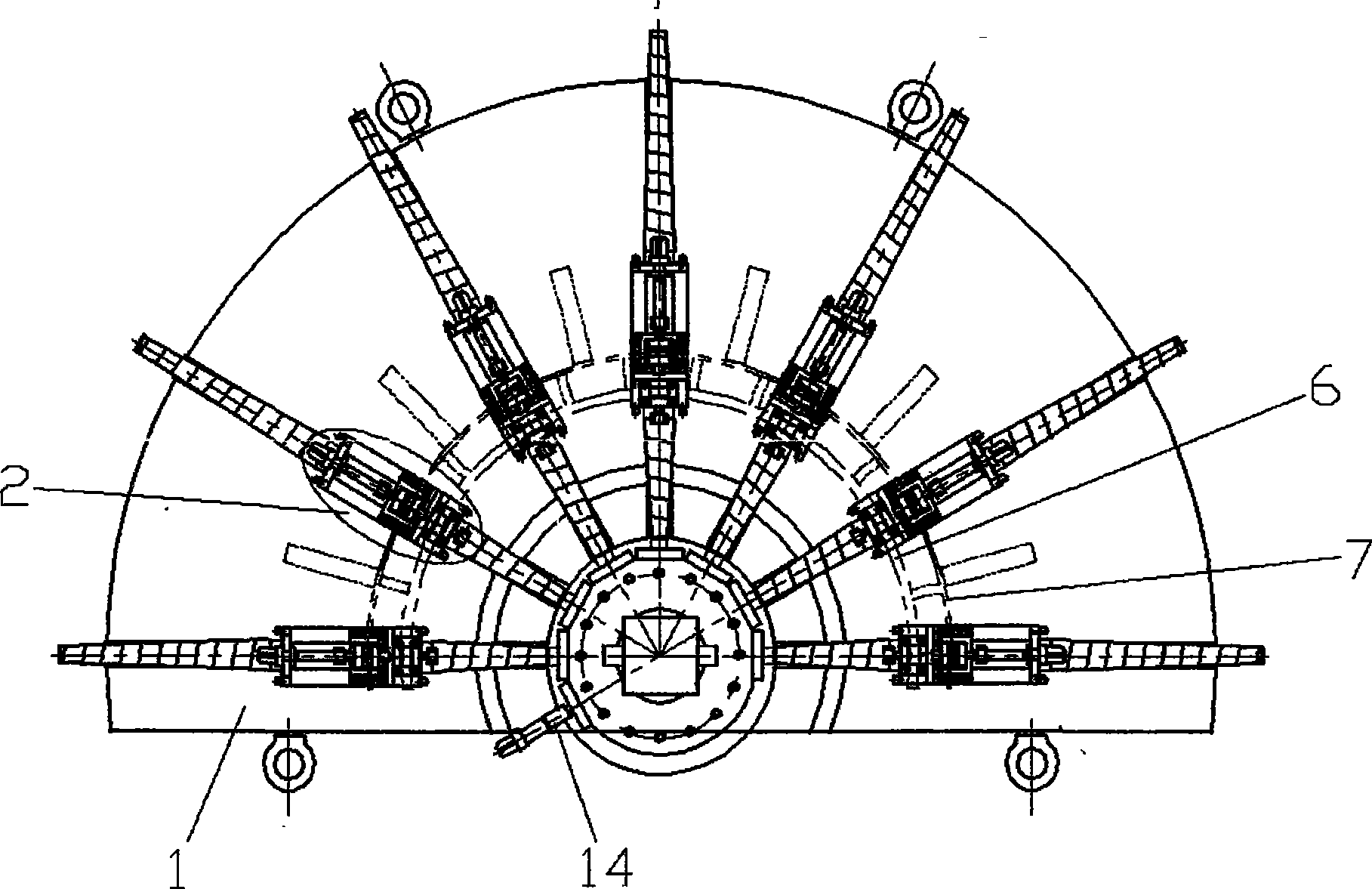

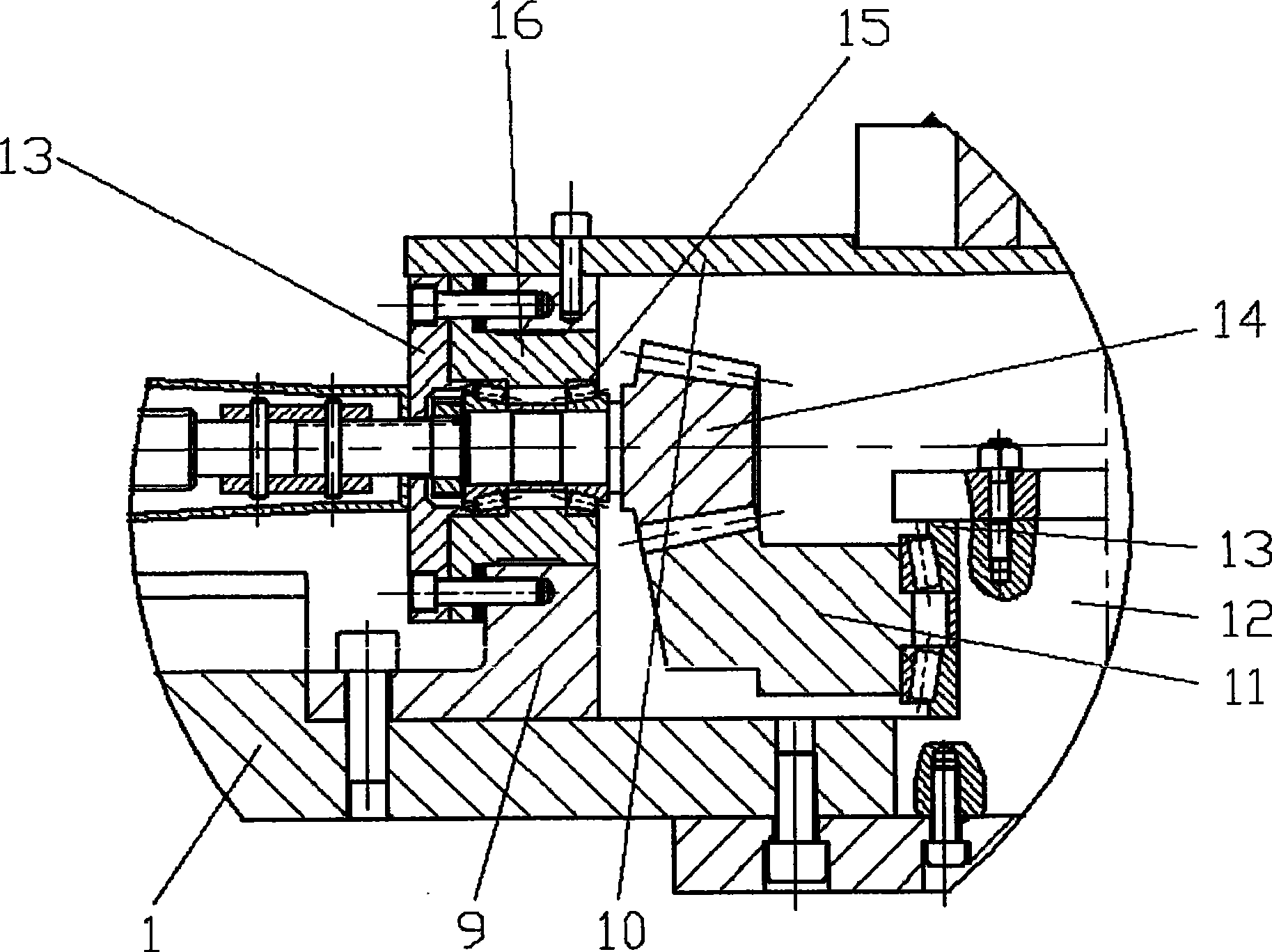

[0022] see figure 1 , figure 2 : This tooling is mainly composed of chassis 1, a plurality of radial sliding devices 2 arranged on the chassis, inner and outer belt clamping mechanisms 3 arranged on the sliding device 2, and arranged in the center of the chassis 1 for driving all sliding devices 2 The synchronously moving transmission mechanism 4 and the cascade arc centering mechanism 5 arranged in the center of the top surface of the transmission mechanism are composed of five parts, and the specific structures of each part are described as follows.

[0023] Chassis 1 is in the shape of a disc with a plurality of trapezoidal chutes 8 on it, seven of which are shown in this example. The chutes are radially distributed with the center of chassis 1 as the origin, and each chute is in On the radius, there is a sliding device 2 radially slidingly matched therein in the chute 8 . The transmission mechanism 4 of the sliding device 2 is arranged in the center of the chassis 1 , s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com