Honeycomb core part machining method based on boss holding

A technology of parts processing and honeycomb core, applied in metal processing equipment, manufacturing tools, details of milling machine equipment, etc., can solve problems such as increasing the production preparation cycle and processing cost of parts, affecting the development cycle of a new generation of aviation equipment, and increasing the cost of auxiliary materials. Achieve the effect of shortening the production preparation cycle, avoiding deformation and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

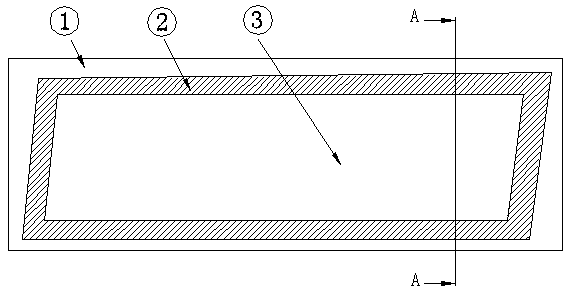

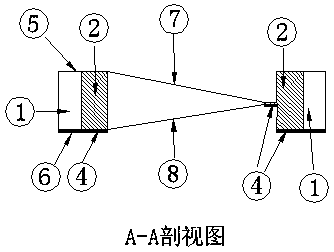

[0020] A method for processing honeycomb core parts based on boss holding, such as figure 1 As shown, the process boss 2 is set along the outline of the part 3, and the remaining process material 1 is connected to the part 3 through the process boss 2; the first surface profile 7 of the part 3 is processed, and the process platform is flush with the profile of the part 3; Then, when turning over the second surface profile 8, a pressing plate is set on the process boss 2 to fix the part 3 with the process boss 2 as a reference.

[0021] During the use of the present invention, qualified honeycomb core parts 3 can be processed without ordering special profile tooling, reducing the processing cost of parts 3; there is no need to use double-sided adhesive tape 4 to hold parts 3, which effectively shortens the parts 3 production preparation period during processing; no need to use alcohol to soak part 3, avoid deformation of part 3 after processing, and ensure the processing qualit...

Embodiment 2

[0023] This embodiment is optimized on the basis of Embodiment 1. After the surface processing of the part 3 is completed, the contour of the part 3 is finally processed, and the process boss 2 around the part 3 is removed. When the second surface profile 8 is turned over, a double-sided adhesive tape 4 is pasted on the process boss 2 .

[0024] After turning over, consider the problem of the connection strength of the boss on the thin side of part 3, and stick the adhesive tape on the thinner process boss 2 to enhance the strength of the boss connection.

[0025] Other parts of this embodiment are the same as those of Embodiment 1, so details are not repeated here.

Embodiment 3

[0027] The present embodiment optimizes on the basis of embodiment 1 or 2, mainly comprises the following steps:

[0028] Step S100: First, trim the blank of the part 3 to obtain the first surface processing positioning surface 5 and the turning surface processing positioning surface 6, and process the first surface of the part 3 based on the repaired first surface processing positioning surface 5 Surface 7, while milling the process boss 2 to be flush with the surface of the part 3, and plane milling the remaining process material 1 to the set thickness;

[0029] Step S200: Then, the part 3 is turned over to process the second surface profile 8, and the process surplus material 1 and the process boss 2 of the turned-over processing positioning surface 6 processed on the first surface are used as a benchmark, and the process surplus material 1, the process Double-sided adhesive tape 4 is pasted on the bonding surface of the boss 2 and the tooling, respectively, to complete the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com