Immersed car hub steel ball cleaning system

A cleaning system, immersion technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc. The frequency of rubbing each other, the cleaning effect is improved, and the surface scratching effect is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

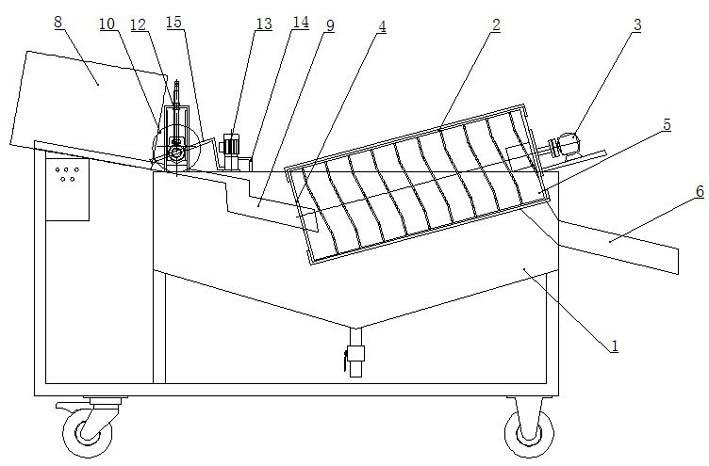

[0018] Such as figure 1 As shown, the present invention relates to a steel ball cleaning system that is not easy to be scratched, has good cleaning effect and is suitable for the preliminary research process. It mainly includes an automatic cleaning device and a ball feeding mechanism arranged at the front end of the automatic cleaning device.

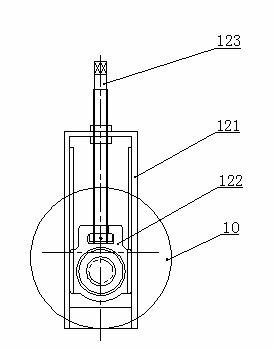

[0019] The above-mentioned automatic cleaning device includes a cleaning tank 1 storing cleaning liquid. Inside the cleaning tank 1, there is a nylon roller 2 with the front end inclined downward. The front end of the roller 2 is inclined downward. A3. The inner wall of the drum 2 is provided with a spiral groove, and the surface of the drum 2 is distributed with through holes. The front and rear ends of the drum 2 are respectively provided with an inlet port 4 and a ball outlet port 5, and a ball outlet channel 6 is provided directly below the ball outlet port 5. . A damping pad is provided on the ball outlet passage 6 below the dru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com